Ballast water treatment system

A treatment system and ballast water technology, applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problems of difficult to remove sediment, increase treatment cost, explosion management efficiency, etc., and save treatment time or cost, high maintenance and management efficiency, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, preferred embodiments of the ballast water treatment system of the present invention will be described in detail with reference to the accompanying drawings.

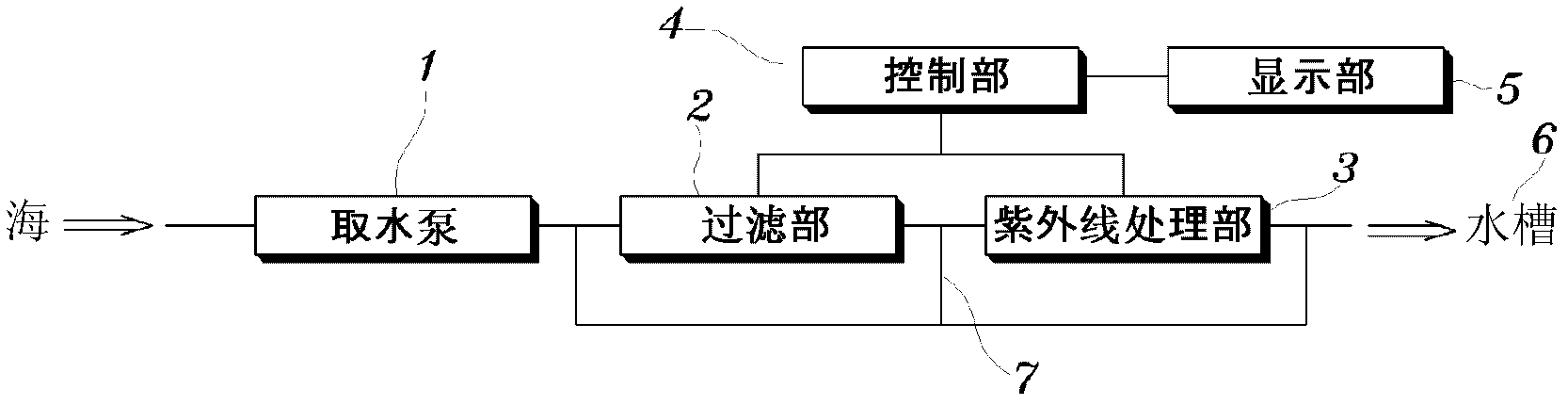

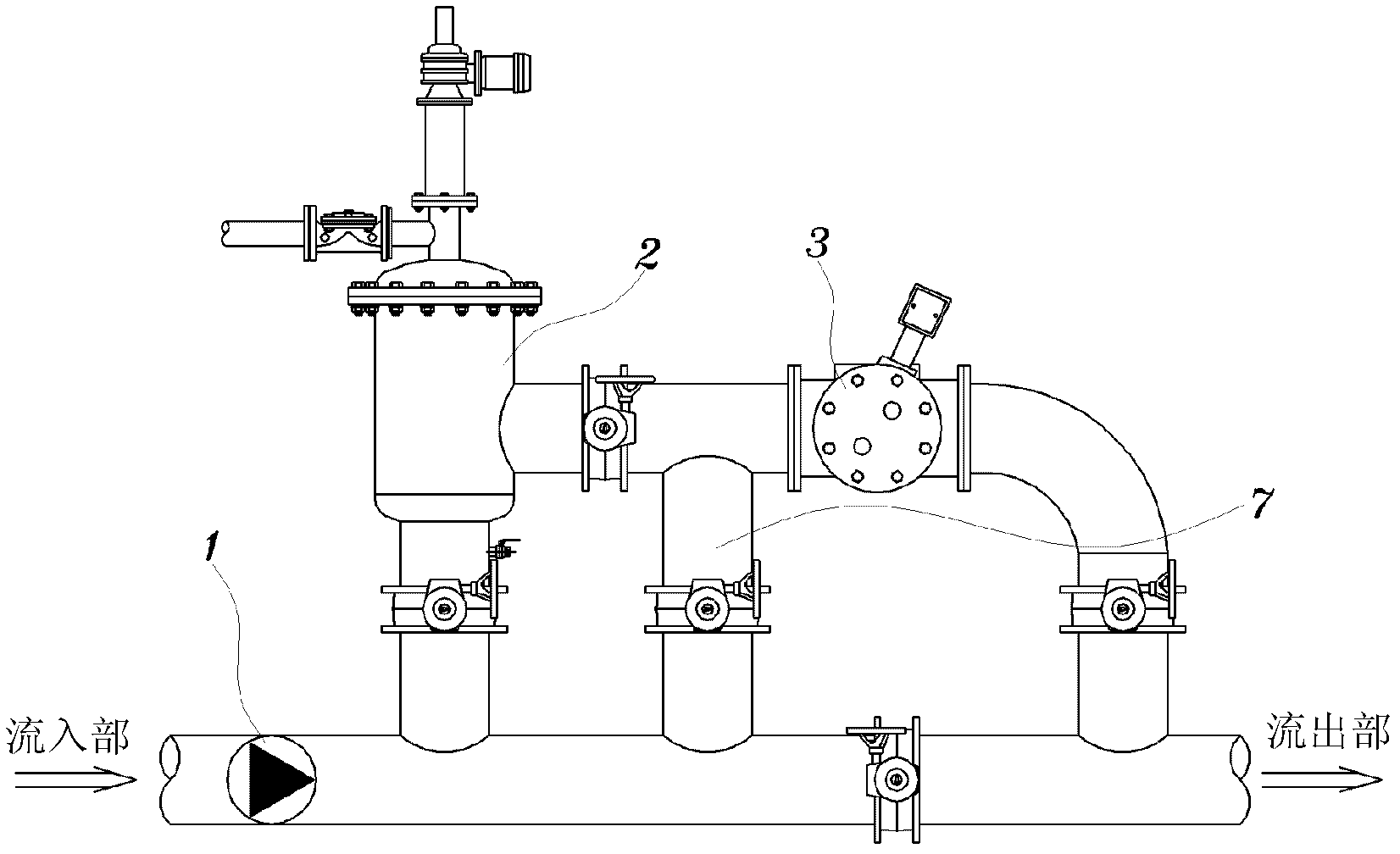

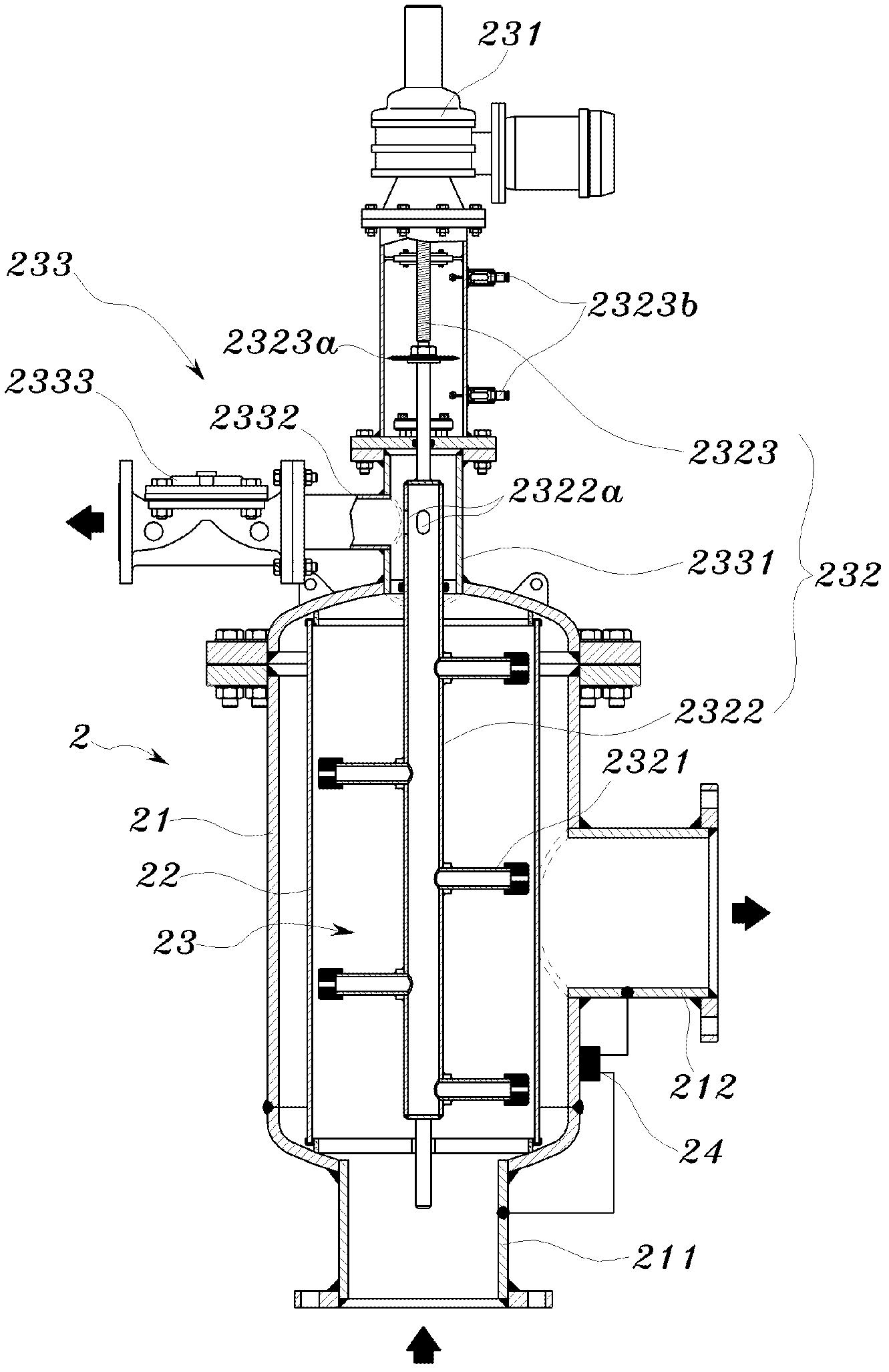

[0057] figure 1 It is a block diagram of a ballast water treatment system according to an embodiment of the present invention; figure 2 It is a systematic diagram of the combination relationship between the filter part and the ultraviolet treatment part of the ballast water treatment system according to an embodiment of the present invention; image 3 It is a sectional view of the filtering part of the ballast water treatment system according to an embodiment of the present invention; Figure 4 It is a partially cut schematic diagram of the ultraviolet treatment part of the ballast water treatment system according to an embodiment of the present invention; Figure 5 It is a schematic diagram of the casing washing part of the ultraviolet treatment part; Figure 6 Photos of experimental equipment u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com