Preparation method for curry powder

A technology of curry powder and raw materials, which is applied in food preparation, application, food science, etc., can solve the problems of insufficient fragrance and full and delicate taste, and achieve the effect of full and delicate taste, low production cost and fragrant smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

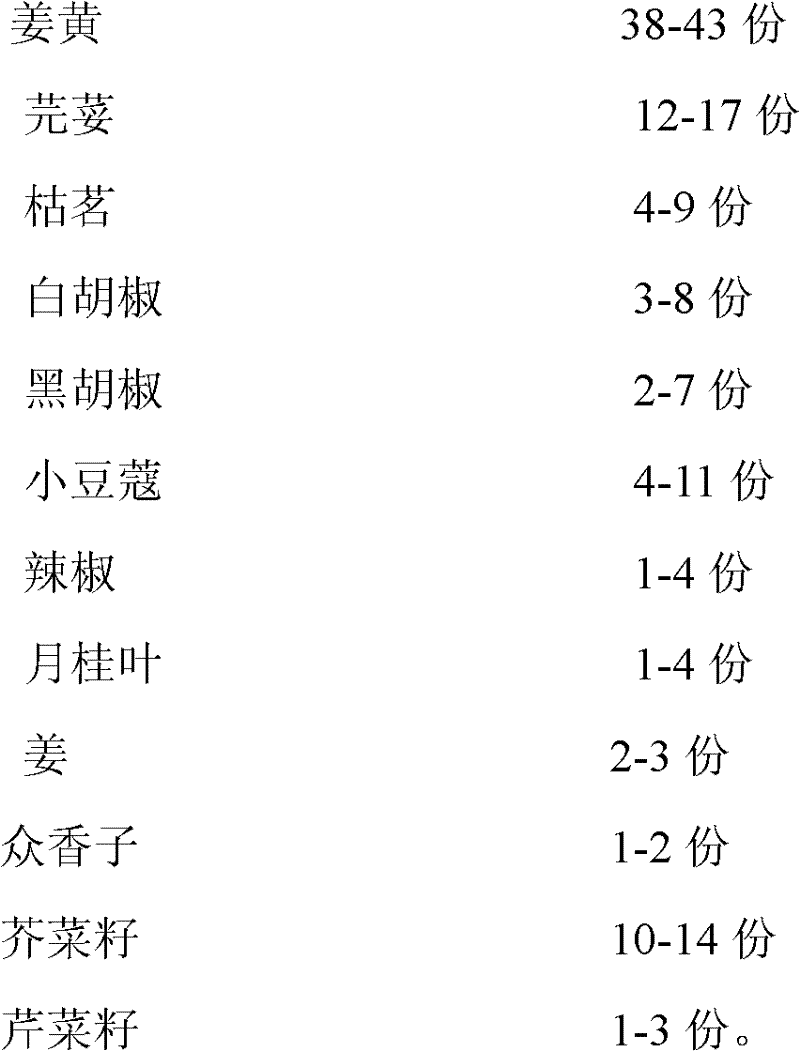

[0016] A kind of curry powder, used raw material and the parts by weight of raw material are:

[0017]

[0018]

[0019] The preparation method of curry powder, comprises the steps:

[0020] Dry the above-mentioned raw materials separately and use a pulverizer to pulverize them, pass the above-mentioned pulverized raw materials through a 60-mesh sieve, and then accurately weigh and feed according to the above-mentioned curry powder formula, and stir and mix evenly. Then put it into a closed pot, dry it at a temperature below 100°C to prevent deterioration during storage, cool it after drying, put it in a aging tank, and age it for about 6 months to make it produce a strong aroma. Finally, it is measured and packaged to obtain a finished product.

Embodiment 2

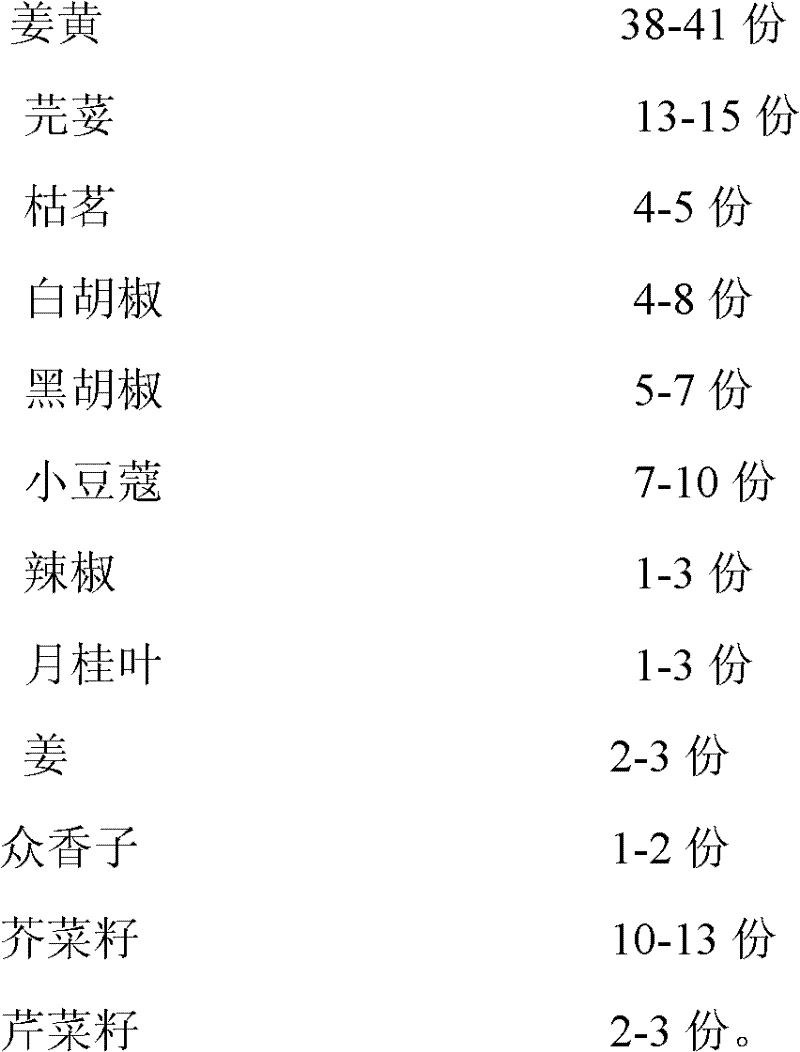

[0022] A kind of curry powder, used raw material and the parts by weight of raw material are:

[0023]

[0024] The preparation method of this curry powder, comprises the steps:

[0025] Dry the above-mentioned raw materials separately and use a pulverizer to pulverize them, pass the above-mentioned pulverized raw materials through a 60-mesh sieve, and then accurately weigh and feed according to the above-mentioned curry powder formula, and stir and mix evenly. Then put it into a closed pot, dry it at a temperature below 100°C to prevent deterioration during storage, cool it after drying, put it in a aging tank, and age it for about 6 months to make it produce a strong aroma. Finally, it is measured and packaged to obtain a finished product.

Embodiment 3

[0027] A kind of curry powder, used raw material and the parts by weight of raw material are:

[0028]

[0029] The preparation method of this curry powder, comprises the steps:

[0030] Dry the above-mentioned raw materials separately and use a pulverizer to pulverize them, pass the above-mentioned pulverized raw materials through a 60-mesh sieve, and then accurately weigh and feed according to the above-mentioned curry powder formula, and stir and mix evenly. Then put it into a closed pot, dry it at a temperature below 100°C to prevent deterioration during storage, cool it after drying, put it in a aging tank, and age it for about 6 months to make it produce a strong aroma. Finally, it is measured and packaged to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com