Aluminium electrolysis flue gas dry purification method

A dry purification and aluminum electrolysis technology, applied in the field of flue gas purification, can solve the problems of deformation of the horizontal cover of the electrolytic cell, low flue gas collection efficiency, low purification efficiency, etc., and achieves easy maintenance, optimized design process control, and reduced maintenance. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

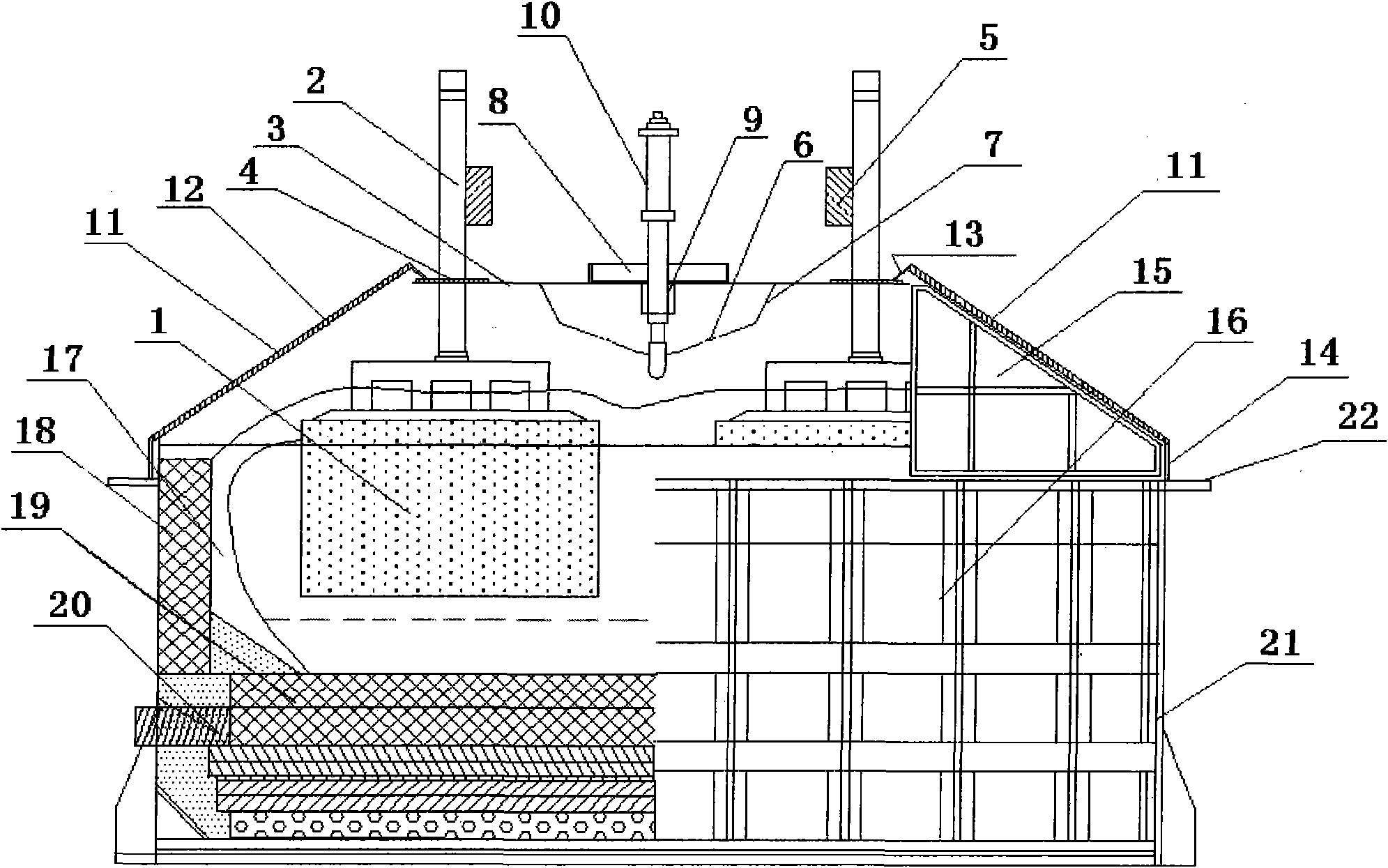

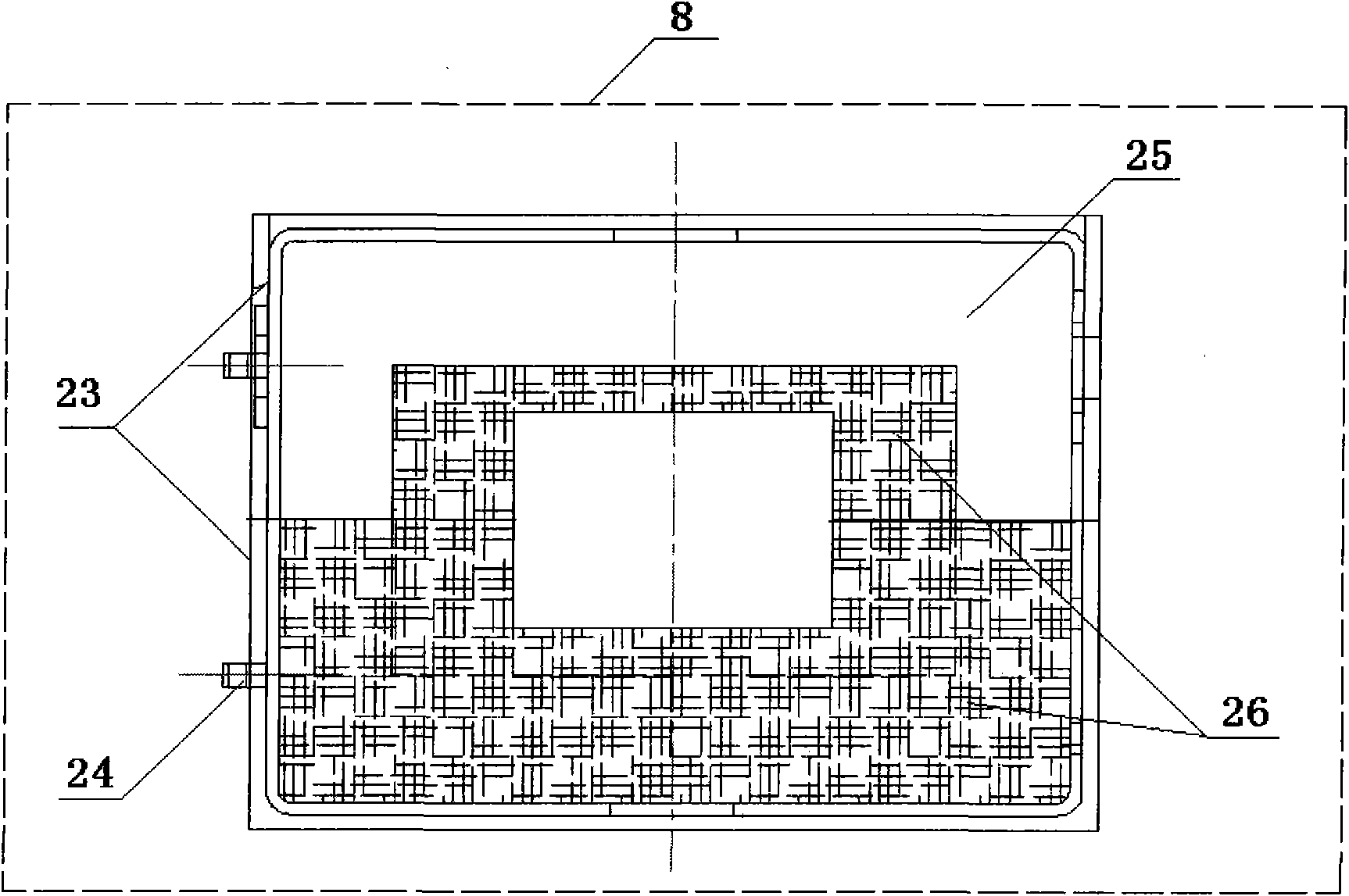

[0044] The technical process of the dry purification method for aluminum electrolysis flue gas of the present invention is that the flue gas generated by the electrolytic cell is collected by the sealed gas collection system of the electrolytic cell, flows through branch smoke pipes and horizontal smoke pipes in sequence, and then enters the underground flue after being collected and aggregated. The electrolytic flue gas is fully mixed and reacted with the fresh alumina uniformly fed through the linear feeder, and the HF gas in the flue gas is adsorbed to complete the adsorption reaction; after the adsorption reaction, the flue gas containing a large amount of fluorine-loaded alumina The channel aggregates and flows into the low-pressure pulse dust collector, and the gas-solid separation is carried out through the bag filter chamber low-pressure pulse dust removal. After separation, the fluorine-containing alumina is collected through the dust hopper of the dust collector, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com