Emergency accident linkage alarm device

An alarm device and accident technology, applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of affecting the blast furnace, delaying time, affecting production, etc., to shorten the accident processing time, reduce the fluctuation of raw material composition, labor The effect of productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings.

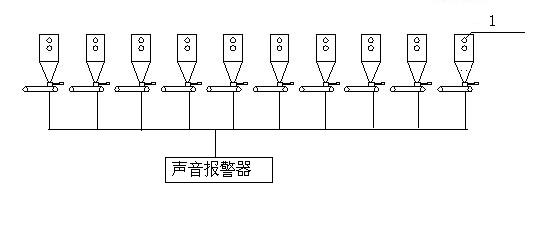

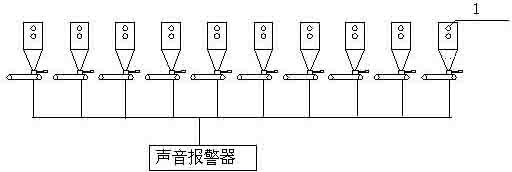

[0012] Such as figure 1 As shown, the meter data monitor of the batching microcomputer control system is equipped with an audible alarm, and the audible alarm is connected to the meter monitoring flowmeter 1 of each small belt scale.

[0013] In the instrument monitoring flowmeter system of each small belt scale, according to the characteristics of the raw materials and the size of the ratio, set the flow fluctuation range control parameters, and the sound alarm is connected with the instrument monitoring flowmeter of each small belt scale. When it exceeds the allowable fluctuation range , The alarm immediately alarms, prompts the on-site batching microcomputer operator, adjusts in time and uses the microphone to notify the batching worker and the first mixing operator to deal with the shortage of material and the moisture of the mixture in time to keep the production order stable.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com