Real-time partial zero compensation optical aspheric surface profile detection method

A technology of zero position compensation and surface shape detection, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of small detection dynamic range and achieve the effects of improving dynamic range, accurate detection and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

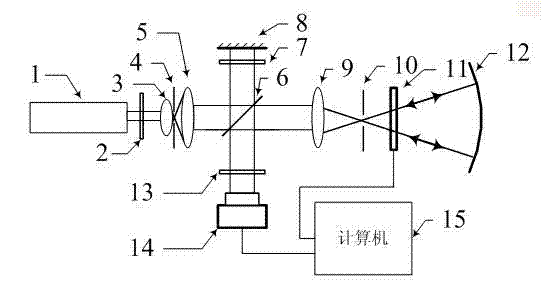

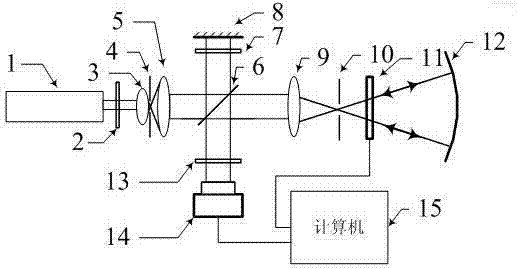

[0026] Embodiment 1: The process of using the present invention to detect the rotationally symmetrical secondary concave aspheric surface type is as follows:

[0027] 1) After beam expansion and collimation, the light emitted from the He-Ne laser is used as an illumination source, and a standard Tieman-Green interference optical path is built. The light in one optical arm is reflected by a standard plane mirror and used as a reference light. The aspheric surface is placed in another optical arm, and the reflected light is used as the object light.

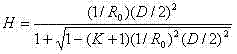

[0028]2) According to the characteristic parameters of the aspheric surface to be measured: quadric surface constant K , Vertex curvature radius R 0 , polynomial coefficient A n , Aspheric diameter D , find the edge sagittal height of the aspheric surface H ,

[0029]

[0030] Then find the best matching spherical radius of the aspheric surface to be tested R , the best matching sphere refers to the sphere that minimizes...

Embodiment 2

[0040] Embodiment 2: The process of utilizing the present invention to detect the surface type of a rotationally symmetric quadratic concave aspheric surface is as follows:

[0041] The difference from Example 1 is step 7), in step 7), the phase modulation range of the selected liquid crystal spatial light modulator is less than 2p: so the phase function y i = y CGH +( i -1)p / 4, i =1, 2, 3, 4, take the modulus of 2p, and then perform binary quantization to obtain the corresponding calculated holograms respectively; then load the holograms on the liquid crystal spatial light modulator in turn, and obtain the +1 order diffraction of the hologram The light wave is used as the illumination light wave, and the light wave returned from the aspheric surface to be tested passes through the hologram to take the +1 order diffracted light, which interferes with the plane reference light wave, and the CCD camera records four phase-shifted interferograms in sequence I i .

[0042] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com