Method for clamping crystal by adopting heat emission heat sink in laser diode end-pumped solid-state laser

A technology of laser diodes and solid-state lasers, applied to lasers, laser components, laser components, etc., can solve problems such as uneven distribution, affecting the quality of output light, and bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

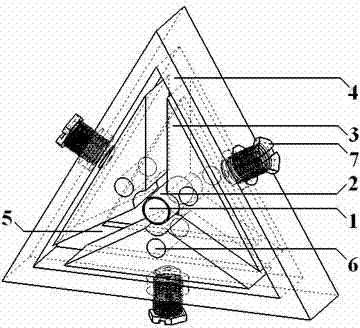

[0016] like figure 1 As shown, for the circular laser crystal 1, the clamping method of three metal heat sinks 3 is adopted, the metal frame 4 is triangular, and there is a metal boss 5 on the metal frame 4, and the metal boss 5 and the metal frame 4 are integral structures, which can be The axial rotation of the laser crystal 1 during clamping is prevented.

[0017] Taking the diameter of the circular laser crystal 1 as 4 mm and the length of 10 mm as an example, connect the vertices of the end face of a whole heat sink to the center point of the surface where it is located. Holes, using the wire cutting method to cut the heat sink along the connecting line into a single piece of metal heat sink 3 with a corresponding number of pieces.

[0018] The width of each side of the metal frame 4 and the width of each metal heat sink 3 is 20 mm, and there is a top wire 7 at the center of each side, and each metal heat sink 3 is fixedly connected to the metal frame 4 through the top w...

Embodiment 2

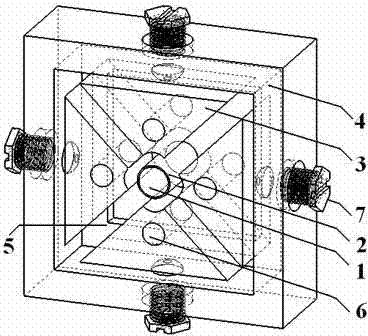

[0022] like figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the clamping method of four metal heat sinks 3 is adopted, and the metal frame 4 is square. The four metal heat sinks are more evenly stressed and have better thermal conductivity.

Embodiment 3

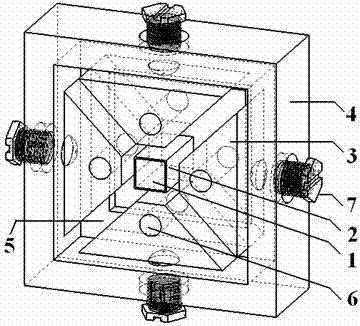

[0024] like image 3 As shown, since the laser crystal 1 has a quadrangular structure, the clamping method of four heat sinks is adopted, and the metal frame 4 is square. The metal frame 4 is provided with a metal boss 5, and the metal boss 5 and the metal frame 4 are integral structures, which can prevent the laser crystal 1 from rotating axially during the clamping process.

[0025] Taking the quadrangular laser crystal 1 with a length and width of 20 mm and a thickness of 10 mm as an example, connect the vertices of the end face of the entire heat sink block to the center point of the face where it is located, and use the wire cutting method to cut the heat sink along the connection line as Four triangular prisms, cut one corner of each triangular prism to obtain a plane parallel to the sides of the original quadrangular prism and the size of the side of the crystal rod 1, and process the clamping surface of each metal heat sink 3 to make it rough is 2 microns.

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com