Powder metallurgy start chainwheel and gear

A powder metallurgy and starting chain technology, applied in the field of gears and powder metallurgy starting sprockets, can solve the problems of waste, poor precision and high scrap rate, and achieve the effects of reducing manpower and material resources, small precision errors and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

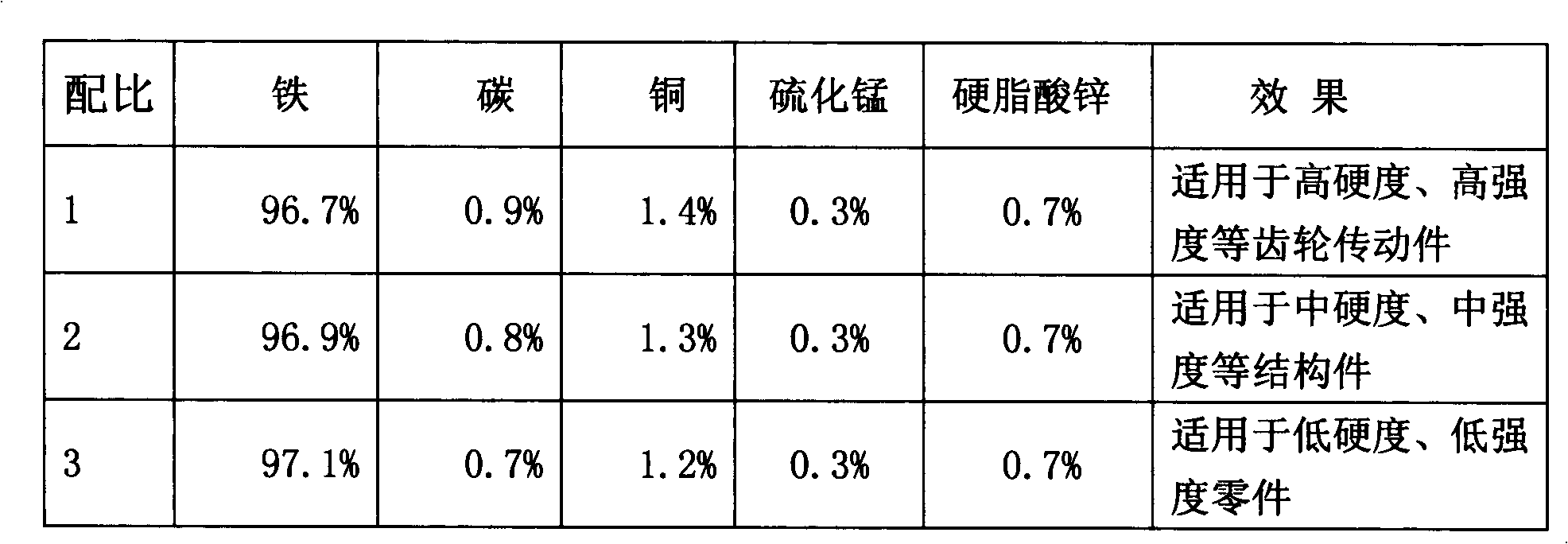

[0040] Raw material weight proportion of the present invention:

[0041]

[0042] Manufacturing method: One-time pressing and forming by powder metallurgy process.

[0043] Process flow: forming, sintering, oil immersion, machining, vibration grinding, cleaning, steam treatment, oil immersion, packaging.

[0044] Forming parameters: machine: 315T hydraulic press

[0045] Pressure: about 250T

[0046] Forming method: female mold floating

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com