Anaerobic reactor capable of controlling methane mixing quantity

An anaerobic reactor and stirring volume technology, which is applied in the field of anaerobic reactors, can solve problems such as poor sludge bulking effect and poor anaerobic treatment effect of sewage, and achieve improved COD removal rate, treatment efficiency, and volume Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

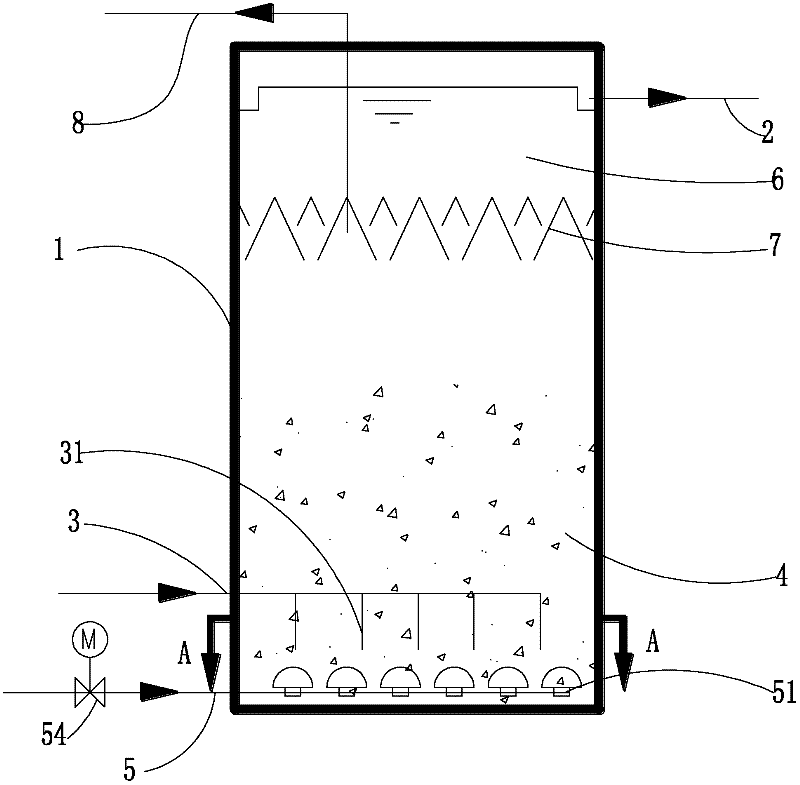

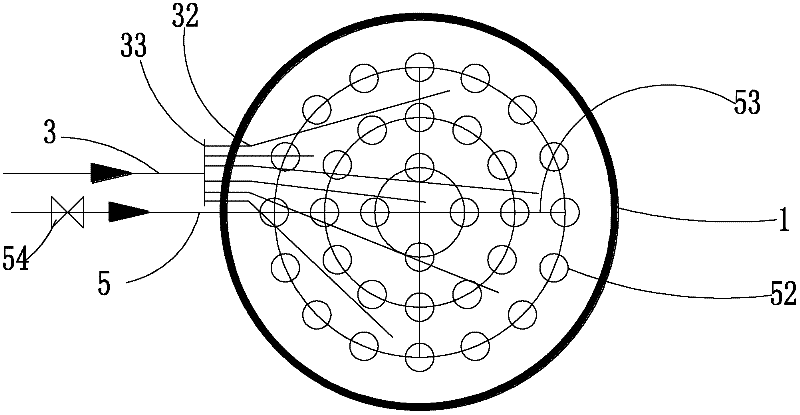

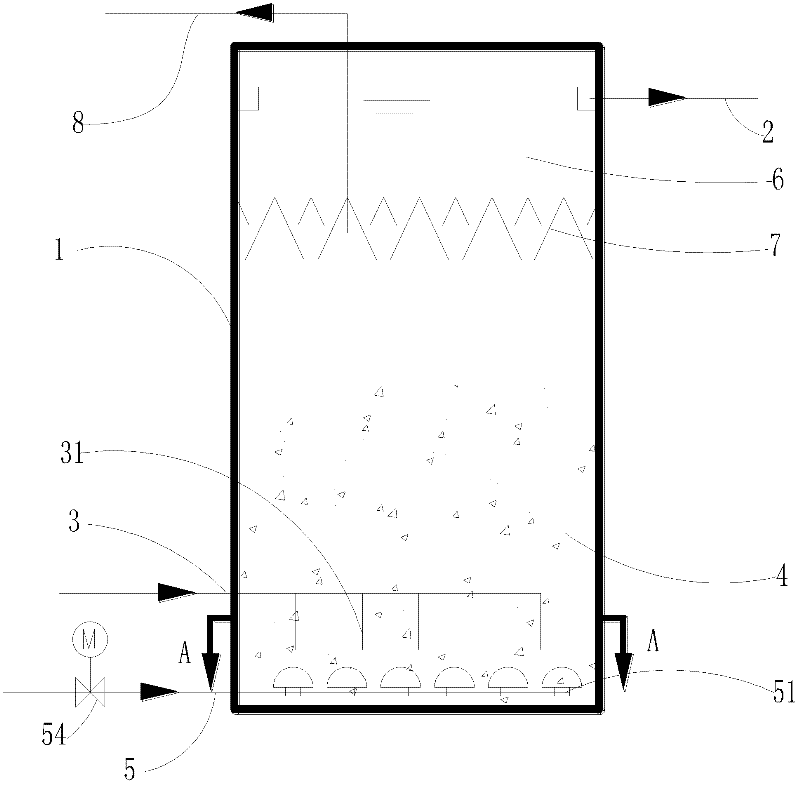

[0029] like figure 1 and figure 2 As shown, in the anaerobic reactor with controllable biogas stirring amount, the upper end of the anaerobic reactor 1 is provided with a purified water outlet pipe 2 for clear water after the treatment of the anaerobic reactor 1, and the lower end of the anaerobic reactor 1 is provided with a supply pipe The wastewater enters the wastewater inlet pipe 3 of the anaerobic reactor 1; the sludge expanded bed 4 is arranged in the anaerobic reactor 1; the biogas inlet pipe 5 controlled by a valve is also arranged at the lower end of the anaerobic reactor 1, the biogas The inlet pipe 5 communicates with the lower end of the anaerobic reactor 1 and the gas outlet of the biogas inlet pipe 5 is lower than the maximum height of the sludge expanded bed 4 . The upper end of the sludge expanded bed 4 is a water outlet clarification area 6, and the upper end of the water outlet clarification area 6 is also provided with a biogas outlet pipe 8, and the biog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com