Treating method for wastewater produced in production of fiber fabrics

A technology for producing wastewater and treatment methods, which is applied in the textile industry wastewater treatment, water/sewage treatment, degassed water/sewage treatment, etc. , The effect of improving biodegradability and reducing pool capacity

Inactive Publication Date: 2017-05-31

达金兰

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the first-level physical and chemical treatment method for domestic fiber fabric production wastewater is to mix and neutralize the acidic wastewater and alkaline wastewater generated in the fiber fabric production process, aerate to remove sulfide, add lime milk to remove zinc, and settle to clarify. It is difficult to meet the national discharge standards, especially the S of wastewater 2- , Zn 2+ and COD are not easy to reach the standard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

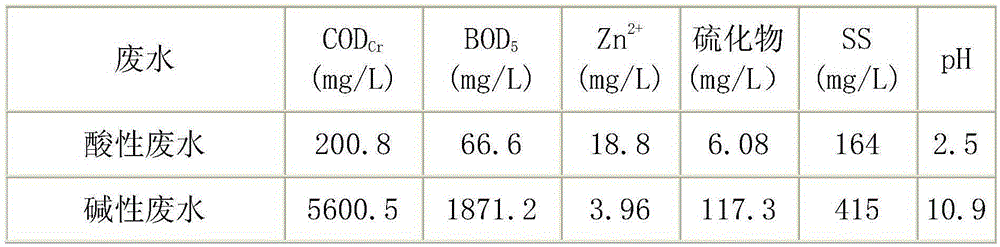

[0017] Example 1. The specific scheme of a method for treating waste water from the production of fiber fabrics is as follows: Table 1 for the quality of raw water.

[0018] Table 1 Water quality of fiber fabric wastewater

[0019]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

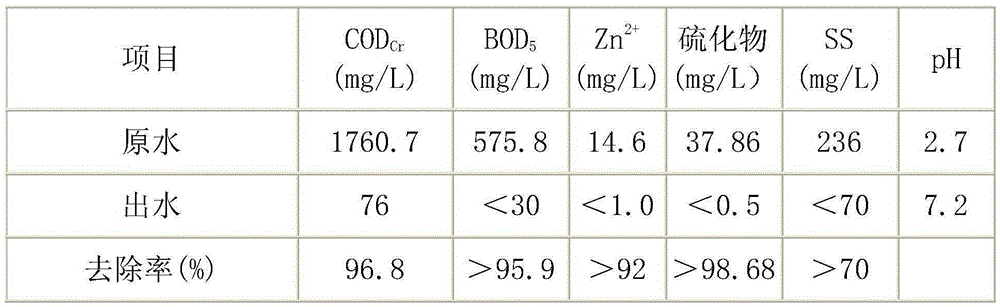

The invention discloses a treating method for wastewater produced in production of fiber fabrics. The method is characterized in that the COD content of effluent having undergone shallow air floatation decreases to 250 mg / L, and the removal rate of COD reaches 87.9%; and after the wastewater undergoes a reaction in an iron filing filtering tower and stays for about 30 min, the content of Zn<2+> in effluent is less than 0.05 mg / L, and the content of sulfide is less than 0.5 mg / L, so treatment requirements on Zn<2+> and sulfide are met. The tank depth of an air floatation apparatus is no more than 650 mm, so the effluent retention time of the apparatus is short (only 3 to 5 min), the surface load of the apparatus is as high as 9.5 to 12 m<3> / (m<2>.h), and the removal rate of suspended solids can reach 85% or above; and effluent of an air-stripping reaction tank enters the procedure of shallow air floatation, and a great amount of fibers are removed and recovered, so pollutant load of subsequent treatment is reduced, and recycling of fiber fabric elements is realized.

Description

technical field [0001] The invention relates to the technical field of industrial wastewater treatment, in particular to a method for treating wastewater from fiber fabric production. Background technique [0002] A large amount of acid and alkali wastewater will be generated during the production of fiber fabrics, and its direct discharge will cause serious water pollution and loss and waste of a large amount of fiber resources. Due to the strong acidity of the mixed wastewater from fiber fabric production and its rich zinc salts and sulfides, it is difficult to treat it. The conventional physical and chemical + biochemical treatment methods have problems such as unstable operation, large floor space and high investment. Research and development are urgently needed. A new method of governance that is reliable and economical. Fiber fabric production wastewater mainly includes acidic and alkaline wastewater, of which acidic wastewater mainly comes from spinning workshops and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/14C02F1/24C02F1/20C02F1/467C02F1/463C02F103/30

Inventor 达金兰

Owner 达金兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com