Method for utilizing waste refractory materials

A technology of waste refractory materials and refractory materials, which is applied in the field of comprehensive utilization of resources, can solve problems such as waste of metal resources, utilization restrictions, and poor resistance to melting damage of construction objects, and achieve the effect of reducing negative impacts and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

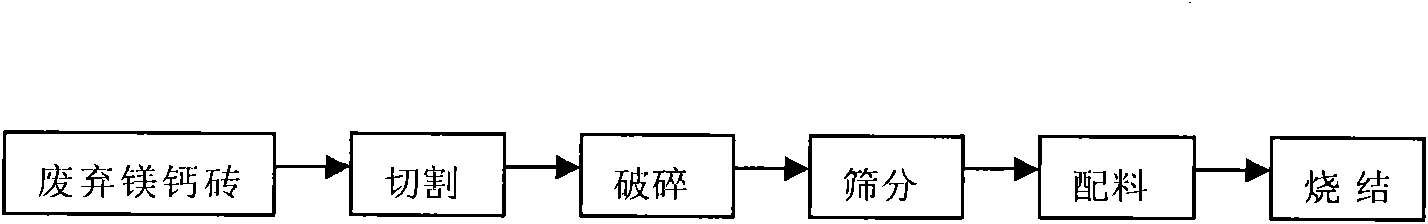

Image

Examples

Embodiment 1

[0017] 1. Cut off the slag layer and metamorphic layer of the waste magnesia-calcium refractories, which are called cutting blocks;

[0018] 2. After crushing the cutting block, it becomes magnesium-calcium powder;

[0019] 3. Sieve out magnesium-calcium powder with a particle size of less than 3mm for batching. The weight percentage of the batching is 27.2% of Jianshan mineral powder, 8.3% of Australian mineral powder, 18% of YD mineral powder, 3% of South African mineral powder, and goblin mineral powder 10.1%, dust removal ash 5%, magnesia-calcium brick powder 2%, limestone 3%, blast furnace return ore powder 13%, lime 5.8%, coke powder 4.5%;

[0020] 4. Pelletizing and granulating: Roller granulating and granulating is carried out according to the above-mentioned ingredients, and the process is the same as the existing granulating and granulating process.

[0021] 5. Sintering: The balls made in the previous step are sintered, and the process is the same as the existing p...

Embodiment 2

[0022] Embodiment two: the percentage by weight of the batching of this embodiment is 27.2% of Jianshan ore, 7.9% of Australian ore, 18% of YD ore, 3% of South Africa ore, 10.1% of goblin ore, comprehensive 5%, magnesia-calcium brick 2.5%, ash Stone 3%, high return 13%, white ash 5.6%, coke powder 4.5, other steps are identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com