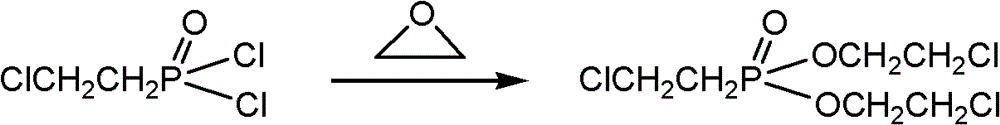

Method for preparing 2-chloroethylphosphonic acid bis(2-chloroethyl)ester

A kind of technology of chloroethyl phosphine dichloride and chloroethyl phosphine dichloride by weight is applied in the field of preparation of 2-chloroethyl phosphonic acid diester, and can solve the problems of high reaction temperature, unsatisfactory yield, complicated post-processing and the like , to achieve the effect of high product purity, less side reactions and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In the dry reaction bottle, install mechanical stirring, thermometer, gas distributor and reflux condenser, place the reaction device in a low-temperature water bath, first use N 2 Replace the air in the bottle twice, add 100.00 g (0.550 mol) of freshly distilled 2-chloroethylphosphine dichloride under the protection of nitrogen, wait until the temperature in the bottle drops below 10°C, start stirring, and quantitatively introduce Ethylene oxide gas 50.88g (1.155mol), feed time about 10h, maintain the reaction temperature at 5-20°C, after feeding, keep the temperature at 30-40°C, continue the reaction for 3h, after the reaction, reduce the pressure The residual ethylene oxide was removed to obtain 146.00 g of the target product with a yield of 98.50% and a GC purity of 98.00%.

Embodiment 2

[0019] In the dry reaction bottle, install mechanical stirring, thermometer, gas distributor and reflux condenser, place the reaction device in a low-temperature water bath, and use N 2 Replace the air in the bottle twice, add 100.00 g (0.550 mol) of freshly distilled 2-chloroethylphosphine dichloride under the protection of nitrogen, wait until the temperature in the bottle drops below 10°C, start stirring, and quantitatively feed it through a gas distributor Ethylene oxide gas 49.67g (1.128mol), feed time about 10h, maintain the reaction temperature at 5-20°C, after feeding, keep the temperature at 30-40°C, continue the reaction for 3h, after the reaction, reduce the pressure The residual ethylene oxide was extracted to obtain 144.96 g of the target product, with a yield of 97.80% and a GC purity of 97.50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com