Converter primary flue gas dry dedusting system

A dry dust removal and flue gas technology, which is applied in the manufacture of converters and the improvement of process efficiency, can solve the problems of explosion venting, converter smelting and the influence of recovered gas volume, etc., to avoid explosion, facilitate management and maintenance, and simplify the system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

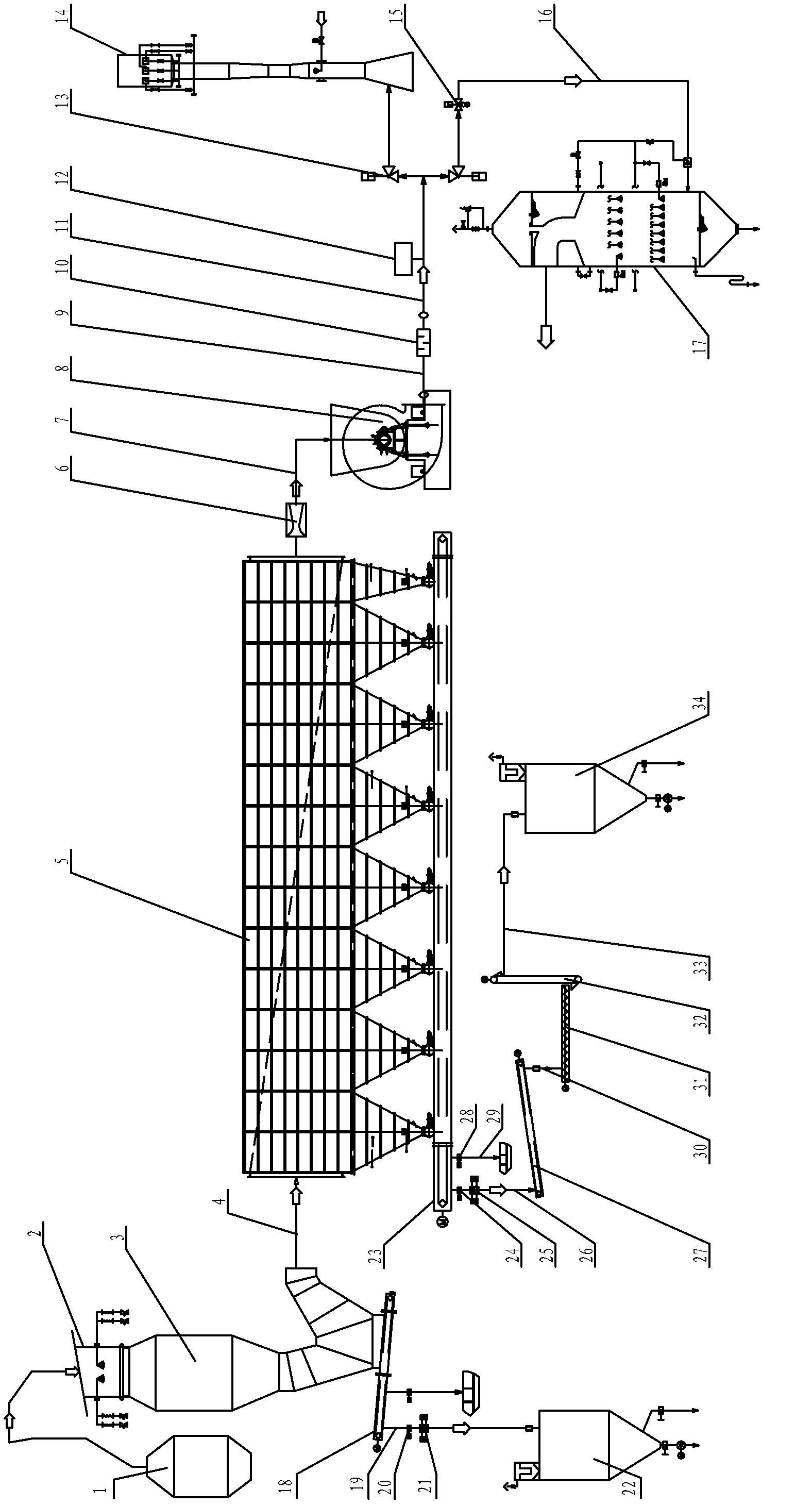

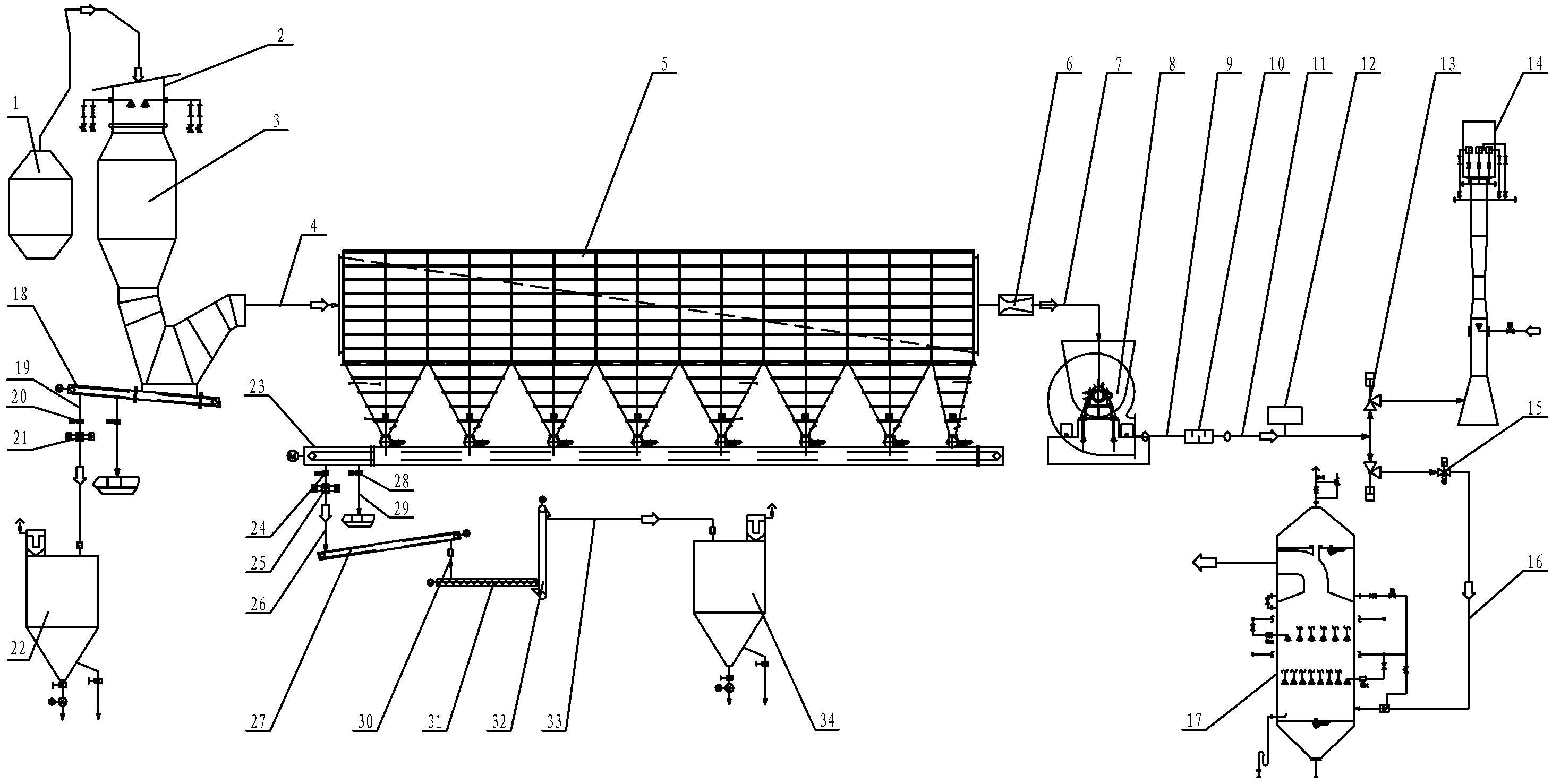

[0012] Such as figure 1 As shown, the vanadium extraction converter primary flue gas dry dedusting system includes evaporative cooling tower 3, first flue gas pipeline 4, high temperature bag filter 5, venturi flowmeter 6, second flue gas pipeline 7, induced draft fan 8. The third flue gas pipe 9, the muffler 10, the fourth flue gas pipe 11, the flue gas composition analyzer 12, the cup valve switching station 13, the diffuser chimney 14, the glasses valve 15, the fifth flue gas pipe 16, the gas cooler 17. Built-in scraper ash conveyor 18, coarse ash unloading pipe 19, first pneumatic flapper valve 20, first pneumatic double-layer flap valve 21, coarse ash bin 22, first scraper ash conveyor 23, The second pneumatic flapper valve 24, the second pneumatic double-layer flap valve 25, the first fine ash discharge pipe 26, the second scraper ash conveyor 27, the accident pneumatic flapper valve 28, the accident ash discharge pipe 29, the first Second fine ash unloading pipe 30, sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com