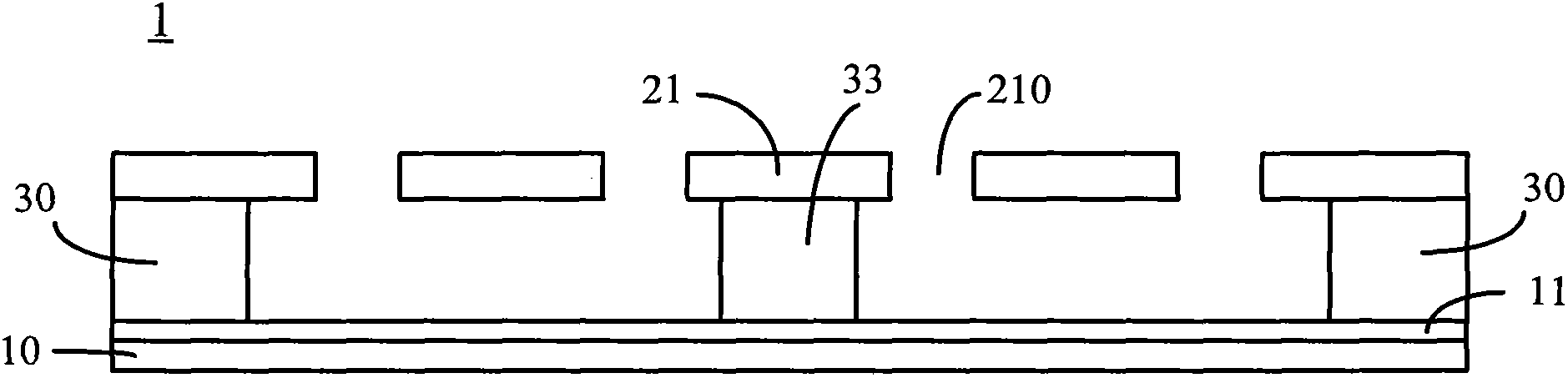

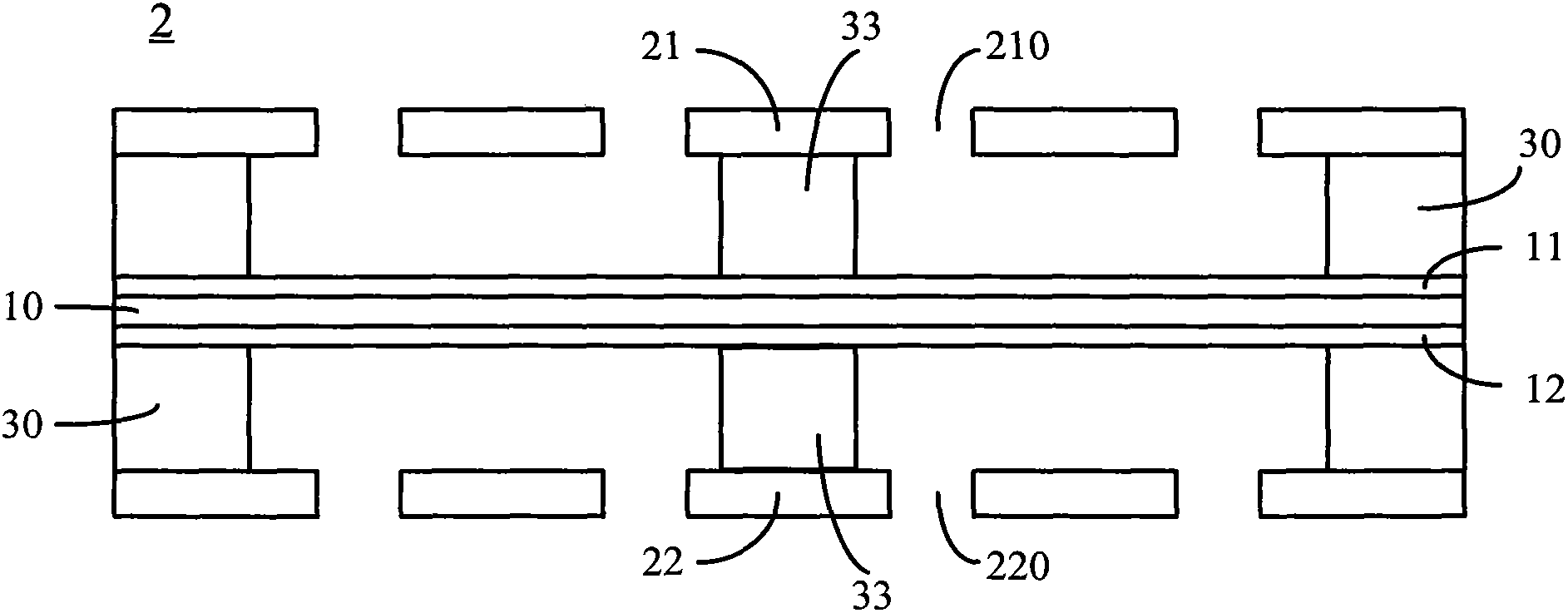

Electrostatic loudspeaker and production method thereof and conductive back board of electrostatic loudspeaker

A conductive backplane and loudspeaker technology, which is applied to electret electrostatic transducers, sensors, electrical components, etc., can solve the problems of reduced electret life and no protection for electrodes, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] With 50 grams of Taipol TPE SBS-4202 (the copolymer of 60% butadiene or isoprene and 40% styrene, purchased from Taiwan Rubber Company) and 5 grams of fluorine-containing cycloolefin (according to U.S. invention patent application 11 / 776,554 No. or British Invention Patent Application No. 0,721,860) into a 2-liter conical flask, add 1,200ml of toluene, stir with a mechanical stirrer at 70°C until the polymer dissolves, and filter the solution with a 0.5μ filter The solution preparation is then completed. Soak the stainless steel conductive mesh (150 mesh) in the above solution for several minutes at room temperature, take it out and dry it at 70°C to complete the protection of the conductive backplane. There is no difference in the conductivity between the surface-protected conductive backplane and the unprotected conductive backplane measured by a three-purpose electric meter (the resistance between any two points on the same conductive backplane is less than 15Ω).

...

Embodiment 2

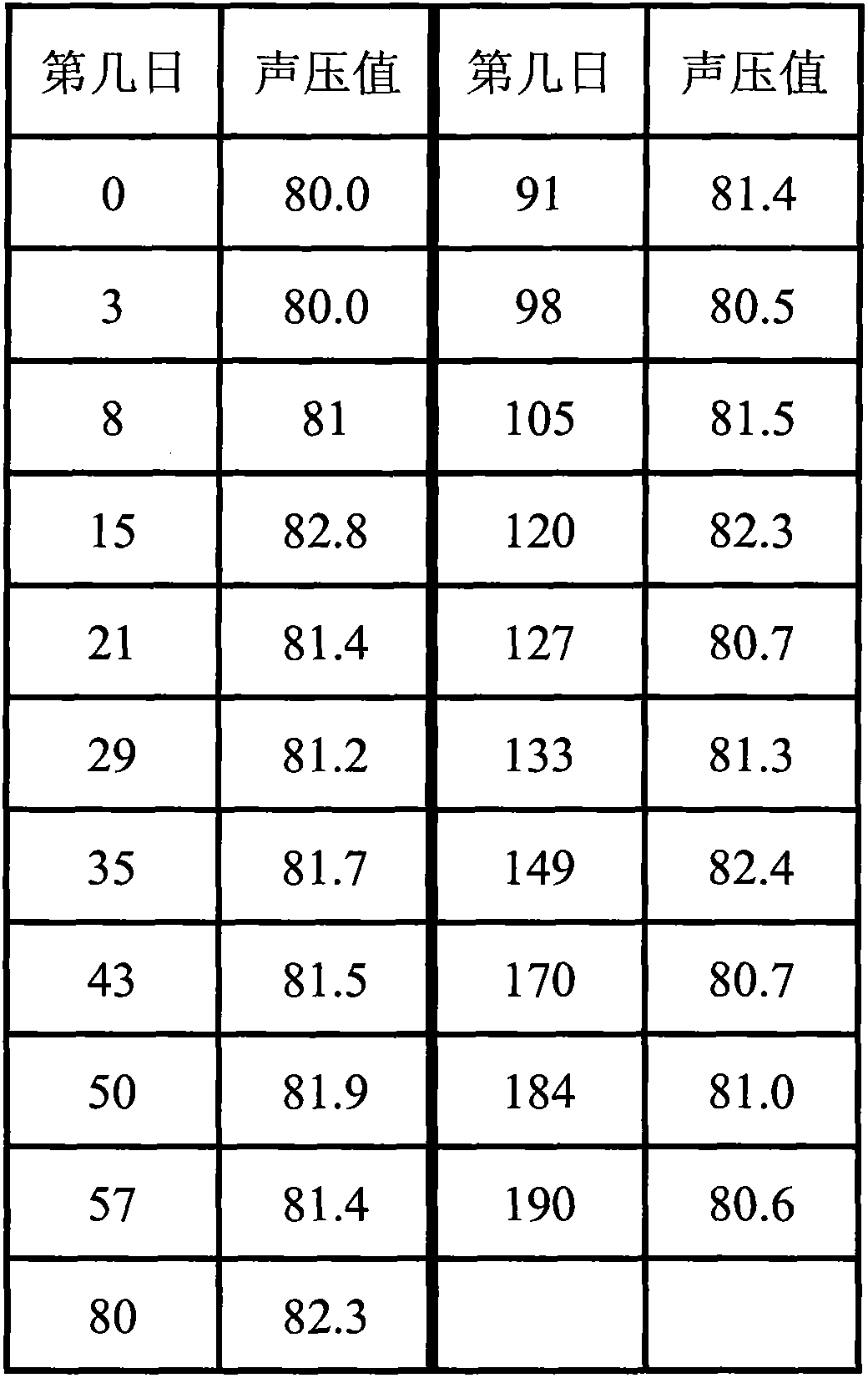

[0056] Dissolve 50 grams of Taipol TPE SBS-4202 and 5 grams of fluorine-containing cyclic olefin (synthesized according to the method of U.S. Patent Application No. 11 / 776,554 or British Patent Application No. 0,721,860) in 300 ml of toluene, spraying This solution is spray-coated on the plastic film conductive backboard (spray-coated on the aluminum-plated surface) of surface aluminized, after drying, make 10 * 14cm as described in embodiment one 2 thin speaker. After testing, there is no significant difference in the sound pressure performance compared with the sound quality and the speaker composed of the unprotected conductive backplane. This proves that the conductive backplane does not affect its sound pressure value after being protected. After 180 days, the sound pressure of the speaker made of the back plate is still maintained at about 83dB. In the experiment of the control group, the sound pressure has dropped to 72dB after 180 days without the protection of the co...

Embodiment 3

[0058] After mixing Asahi's fluorine-containing coating Lumiflon LF200 (Tg: 35°C; OH value: 52mg KOH / g-polymer; specific gravity: 1.12) with a crosslinking agent containing unsaturated monomers of isocyanate, spray the coating Spray the solution on the stainless steel conductive mesh (60 mesh), take it out and dry it at 80°C for 3 hours to complete the protection of the conductive backplane. Make 10×14cm as described in Example 1 2 The sound pressure performance of the thin speaker has no significant difference from the sound quality and the speaker composed of the unprotected conductive backboard. However, the service life of the speaker made of the polymer-protected conductive backboard is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com