Polyacrylate polymer terminated cyclodextrin polyrotaxane and preparation method thereof

A polyacrylate and cyclodextrin technology, applied in the field of polymer-terminated cyclodextrin polyrotaxane and its preparation, can solve problems such as single method, and achieve the effect of low price and widening scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

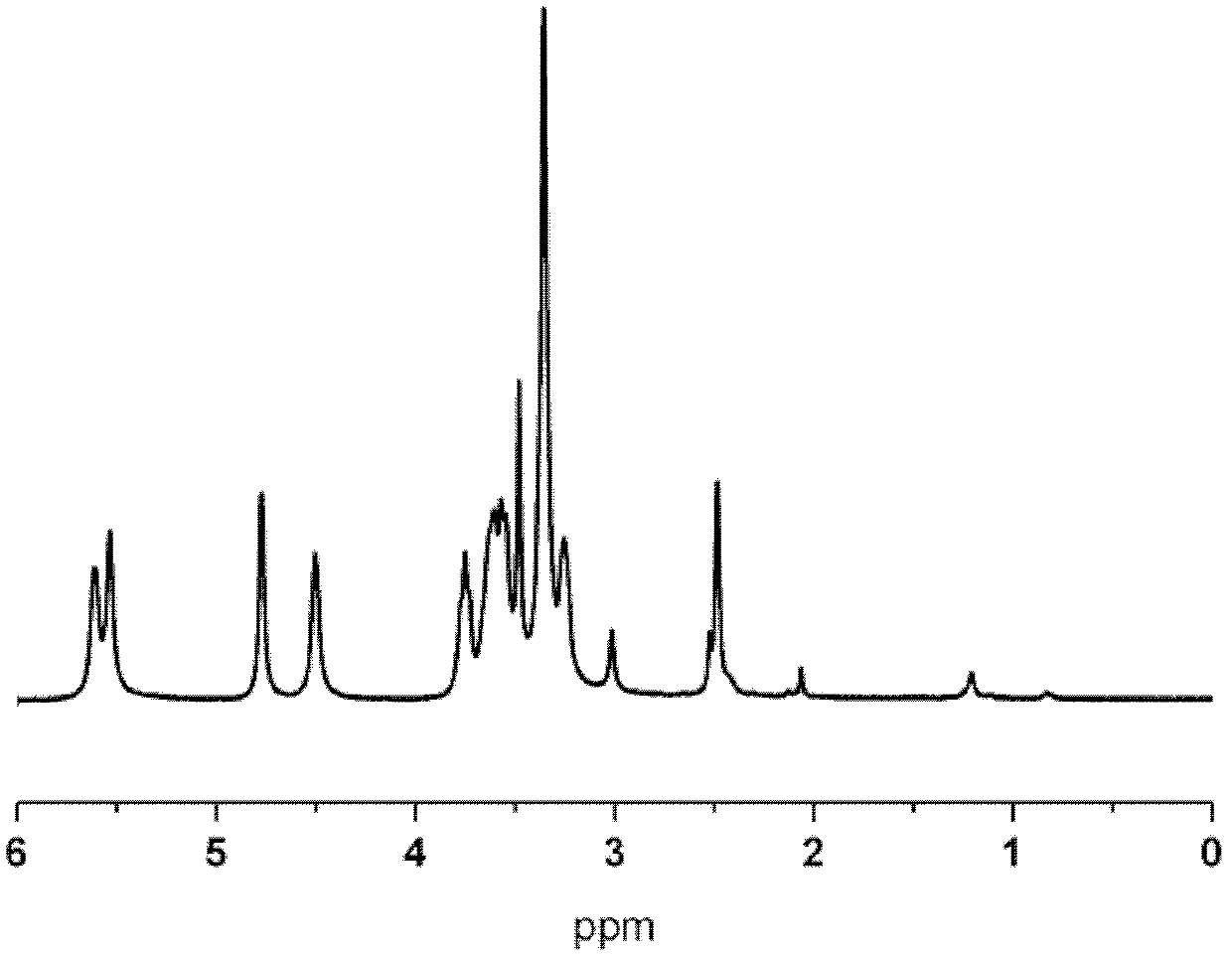

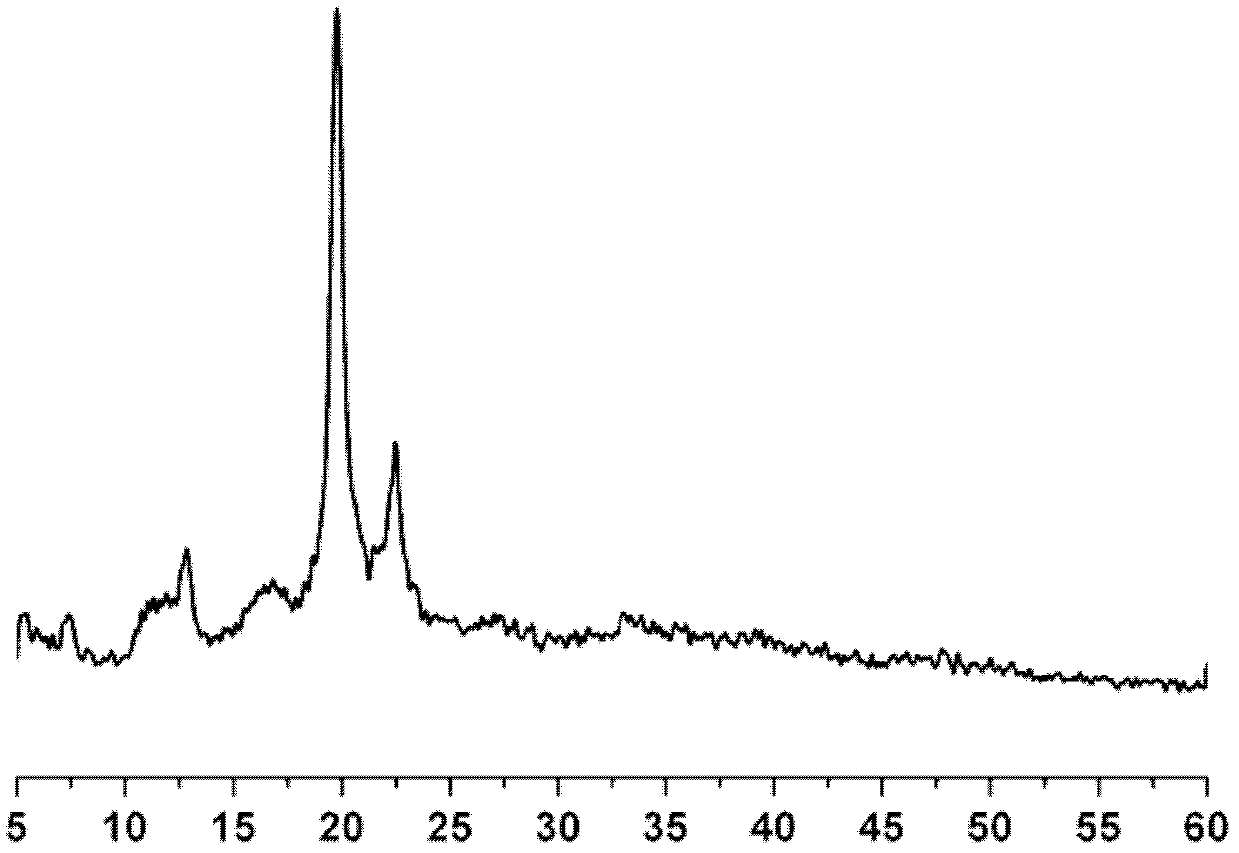

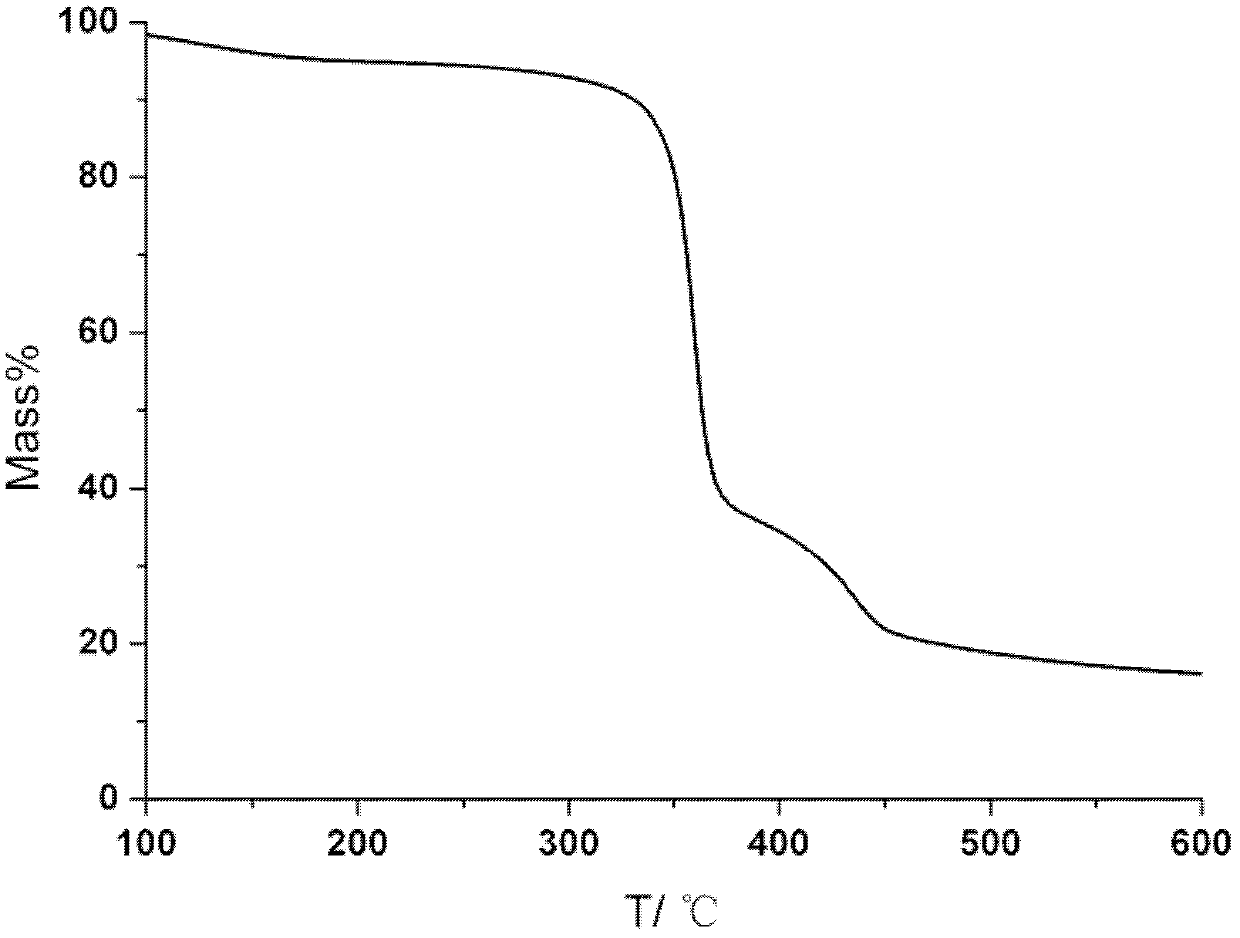

Method used

Image

Examples

Embodiment 1

[0024] Step a: at room temperature, 5 grams of polyethylene glycol dimercaptoacetate (average molecular weight 6100) aqueous solution with a mass percent concentration of 15% and 42.5 grams of an α-cyclodextrin aqueous solution with a mass percent concentration of 11.27% were stirred Mix evenly, wherein the molar ratio of polyethylene glycol dimercaptoacetate to α-cyclodextrin is 1:40; the mixed solution is left to stand at room temperature for 24 hours to obtain a non-flowing gel-like polypseudorotaxane physical condensation glue;

[0025] Step b: Add 4 grams of dimethylaminoethyl acrylate monomer and 8 mg of azobisisobutyronitrile free radical initiator powder to the polypseudorotaxane physical gel obtained above, stir and mix evenly to obtain a white Heterogeneous suspension; the above-mentioned white heterogeneous suspension was placed in a 365 nm ultraviolet dark box analyzer and reacted for 28 hours;

[0026] Step c: After the reaction is completed, add 400 milliliters ...

Embodiment 2

[0036]Step a: at room temperature, 5 grams of polyethylene glycol dimercapto propionate (average molecular weight 10200) aqueous solution and 50 grams of α-cyclodextrin aqueous solution with a mass percent concentration of 11.27% were stirred under the condition of stirring Mix evenly, wherein the molar ratio of polyethylene glycol dimercaptopropionate to α-cyclodextrin is 1:47; the mixed solution is allowed to stand at room temperature for 24 hours to obtain a non-flowing gel-like polypseudorotaxane physical condensation glue;

[0037] Step b: Add 10 grams of dimethylformamide solution of 30% n-butyl acrylate monomer and 30 mg of azobisisobutyronitrile free radical to the polypseudorotaxane physical gel obtained above Initiator powder, obtain a kind of white heterogeneous suspension after stirring and mixing; Above-mentioned white heterogeneous suspension is placed in 365 nanometer ultraviolet dark box analyzer and reacted for 18 hours;

[0038] Step c: After the reaction is...

Embodiment 3

[0044] Step a: at room temperature, 5 grams of polyethylene glycol dimercaptopropionate (average molecular weight 4200) aqueous solution and 10 grams of α-cyclodextrin aqueous solution with a mass percent concentration of 11.27% were stirred under the condition of stirring Mix evenly, wherein the molar ratio of polyethylene glycol dimercaptopropionate to α-cyclodextrin is 1:9.7; the mixed solution is allowed to stand at room temperature for 24 hours to obtain a non-flowing gel-like polypseudorotaxane physical condensation glue;

[0045] Step b: Add 20 grams of dimethyl methacrylate monomer solution in dimethylformamide with a mass percent concentration of 20% and 80 mg of azobisisobutyronitrile free Base initiator powder, after stirring and mixing, obtain a kind of white heterogeneous suspension; Above-mentioned white heterogeneous suspension is placed in 365 nanometer ultraviolet dark box analyzer and reacted for 24 hours;

[0046] Step c: After the reaction is completed, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com