Interfacial debonding monitoring method for steel tube concrete tube wall based on piezoelectric impedance measurement

A technology of concrete-filled steel tube and interface peeling, which is applied in the direction of material impedance and can solve the problems of expensive sensing and testing systems and poor shear resistance of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

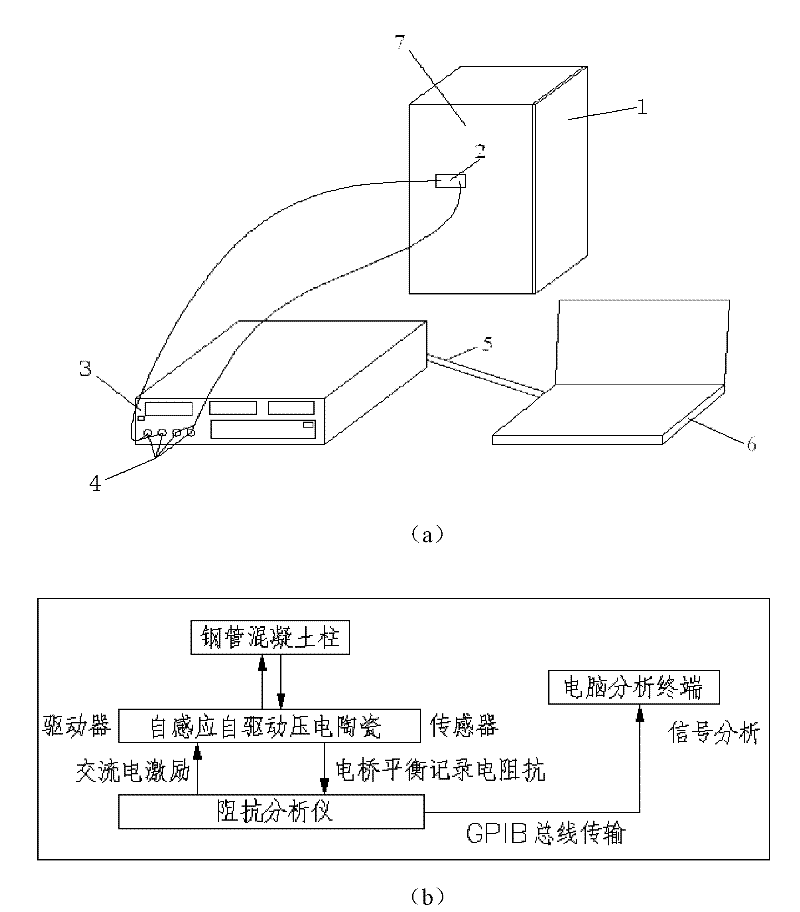

[0059] The monitoring method for the interface peeling of concrete filled steel pipe wall based on piezoelectric impedance measurement is as follows:

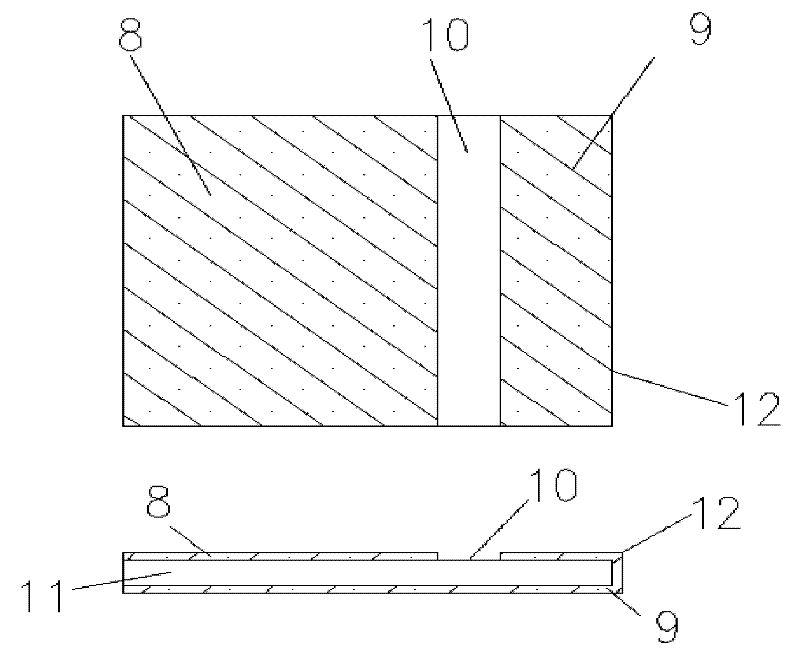

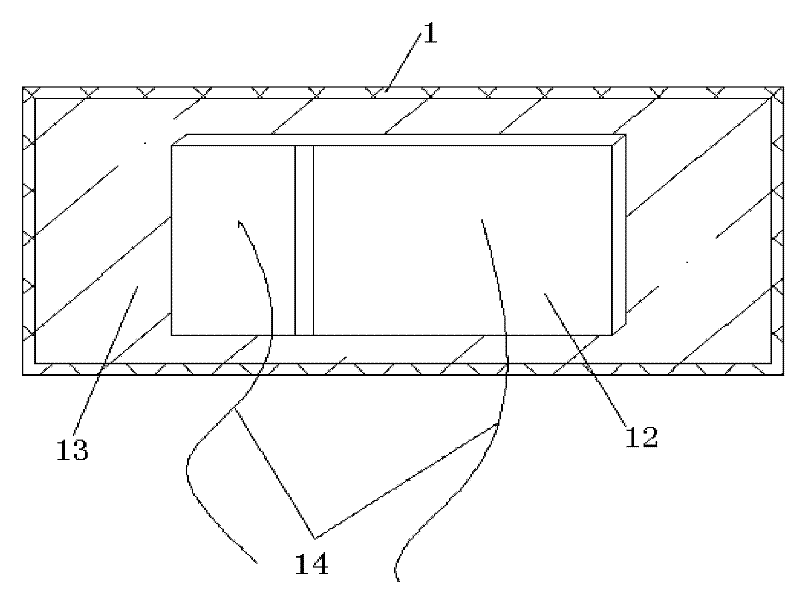

[0060] 1) A piezoelectric ceramic sheet is pasted on the steel pipe surface of the steel tube concrete member as a self-driven self-inductor;

[0061] 2) The impedance analyzer applies AC voltage to the piezoelectric ceramic sheet pasted on the surface of the steel pipe concrete member of the monitored object, and the ratio of input voltage to output current at different frequencies is obtained according to the balance of the bridge, so as to obtain piezoelectric ceramic sheets in different frequency bands and The impedance of the electromechanical coupling system composed of the monitored concrete filled steel pipe;

[0062] 3) Using the GPIB data bus to transmit the collected electromechanical coupling impedance signal to the computer analysis terminal;

[0063] 4) Select the electromechanical coupling impedance measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com