Sample formed component analyzer automatic detection control apparatus and control method thereof

A component analysis and automatic detection technology, applied in the direction of analyzing materials, comprehensive factory control, comprehensive factory control, etc., can solve the problems of reducing manual re-inspection rate, time-consuming and labor-intensive inspection, etc., to overcome slow analysis speed, increase detection speed, improve The effect of detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

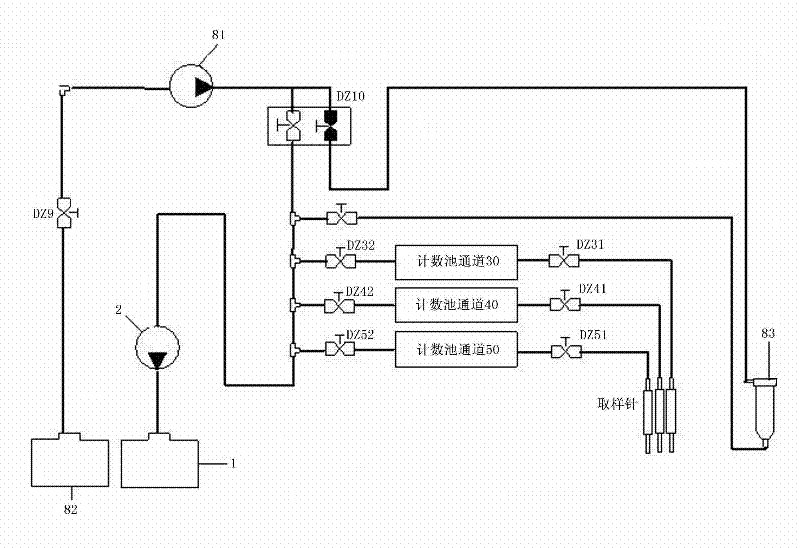

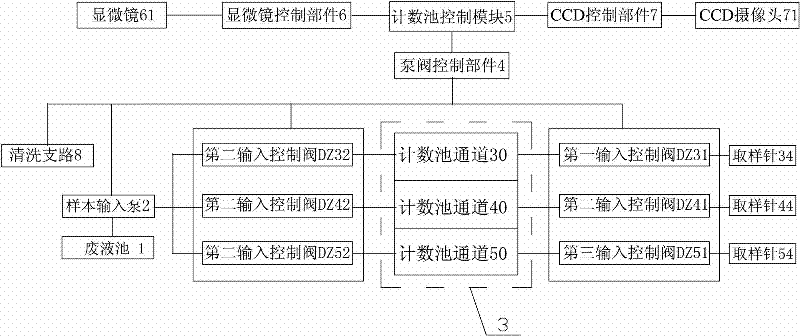

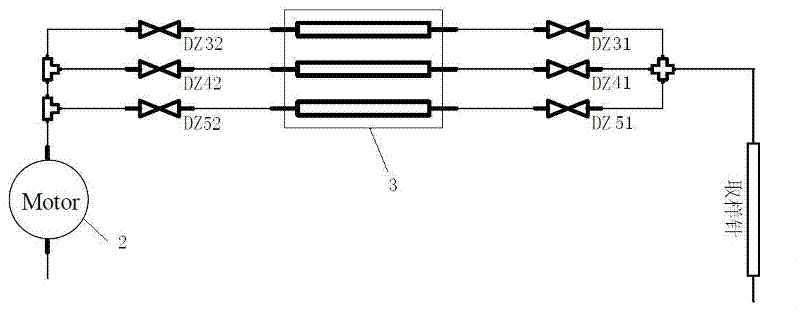

[0029] Such as figure 1 , figure 2 As shown, the multi-channel processing module in the automatic inspection control device of the sample formed component analyzer of the present invention includes a flow counting cell 3, and the flow counting cell 3 includes at least two channels arranged side by side. In this example, three channels (30, 40, 50) are taken as an example. These channels ( 30 , 40 , 50 ) are all made of optical glass material, and all have the same standard volume and standard cavity thickness. These channels (30, 40, 50) are respectively provided with independent input ends and output ends, and the input ends are respectively connected to the sampling needles (34, 44, 54) through the first input control valves (DZ31, DZ41, DZ51), The output end is connected to the sample input pump 2 through the second input control valve (DZ32, DZ42, DZ52), and the output end of the sample input pump 2 is connected to the waste liquid pool 1. The first input control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com