Selective harm-reducing cigarette and preparation method thereof

A selective and cigarette technology, applied in the field of processing and cigarette manufacturing, can solve the problems of reducing the smoking quality of cigarettes and the loss of tar flavor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

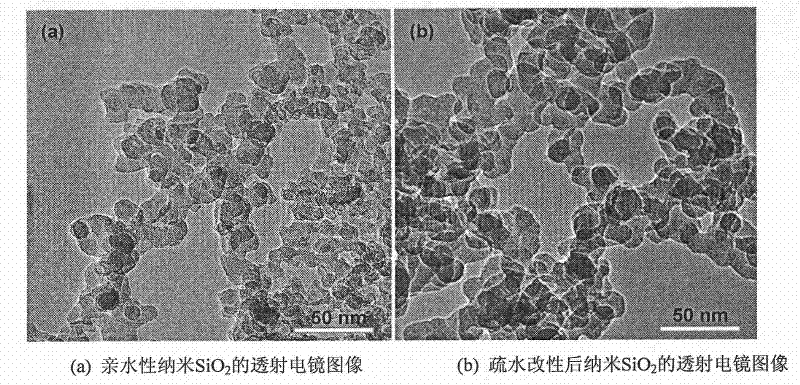

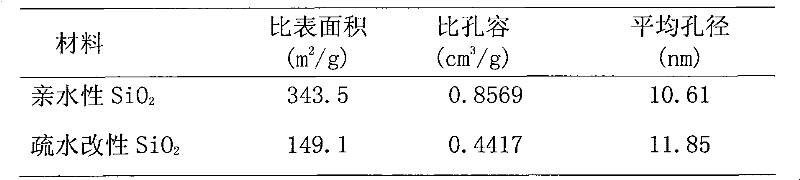

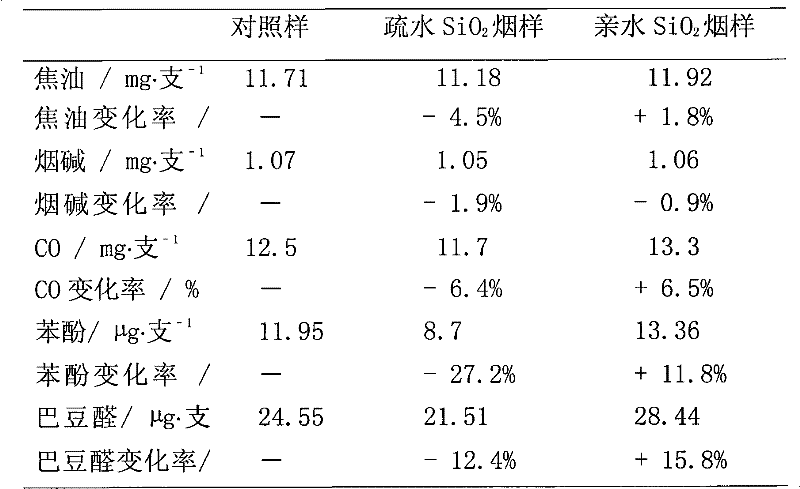

[0023] 1Kg hydrophilic SiO 2 The nanoparticles were calcined at 500 °C for 5 h to increase the SiO 2 The Si-OH content on the surface of the nanoparticles was placed in a closed reactor after cooling, and the SiO was slowly heated under the protection of nitrogen. 2 Nanoparticles to 150 ° C and keep the temperature constant, feed SiO into the closed reactor 2 Trimethylchlorosilane with 10% weight of nanoparticles, stop heating after reacting for 6h, naturally cool to room temperature, wash with ethanol, and then dry, the resulting product is trimethylchlorosilane modified nano-SiO 2 particles, i.e. hydrophobic nano-SiO 2 particle. nano-SiO 2 The specific surface and pore structure data of particles before and after modification are shown in Table 1 below. Hydrophilic and hydrophobic nano-SiO 2 The TEM image of the particle is shown in the figure.

[0024] Table 1 Hydrophilic nano-SiO 2 Microstructural data of particles before and after hydrophobic modification

[0025]...

Embodiment 2

[0030] Before cigarette, the hydrophobic nano SiO that embodiment 1 makes 2 The particles are added to the tobacco feed liquid at a ratio of 1.0% by weight of the tobacco leaves, stirred evenly, added to the tobacco leaves together with the feed liquid, and then other processes of cigarette processing are performed.

Embodiment 3

[0032] When the papermaking method is used to produce reconstituted tobacco leaves, the hydrophobic nano-SiO obtained in Example 1 2 The particles are added to the slurry or dipping coating at a ratio of 2.0% by weight of the tobacco leaves, and then fully stirred to fully disperse the nanomaterials in the slurry or dipping coating, and then enter the process of making, drying, chipping, etc. with the slurry or dipping coating The processing procedure of reconstituted tobacco leaves, and finally add the reconstituted tobacco leaves to the tobacco leaf formula in proportion to produce cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com