One-spot method for converting lutein ester into zeaxanthin

A technology of zeaxanthin and lutein ester, applied in chemical instruments and methods, organic chemistry, azo dyes, etc., can solve the problems of low conversion rate and cumbersome steps, and achieve high yield, simple operation and simple steps short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

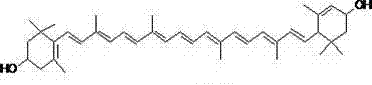

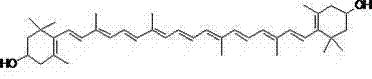

Image

Examples

Embodiment 1

[0026] Under the protection of nitrogen, measure 5mL of 1,2-propanediol in a 25mL three-neck flask, heat up to 80°C, weigh 0.5g of lutein extract and dissolve it in the solvent. After the lutein is dissolved, weigh 2g of solid hydrogen Potassium oxide was added to the reaction solution, the temperature was raised to 110°C, and the reaction was kept for 48 hours. Add 10 volumes of distilled water, stir evenly, adjust the pH to neutral with 25% acetic acid, then filter, and wash the filter cake with distilled water 3 times to remove residual chemicals and various salts. The cake was vacuum dried. As determined by HPLC, lutein accounts for 6% and zeaxanthin accounts for 88%.

Embodiment 2

[0028] Under the protection of nitrogen, measure 30mL of 1,2-propanediol in a 100 mL three-neck flask, heat up to 60°C, weigh 3g of lutein extract and dissolve it in the solvent. After the lutein extract is dissolved, weigh 15g Solid potassium hydroxide was added to the reaction solution, the temperature was raised to 110°C, and the reaction was kept for 48 hours. Add 10 volumes of distilled water, stir evenly, adjust the pH to neutral with 25% acetic acid, then filter, and wash the filter cake with distilled water 3 times to remove residual chemicals and various salts. The cake was vacuum dried. As determined by HPLC, lutein accounts for 5% and zeaxanthin accounts for 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com