Preparation method of vacuum pressure impregnation resin

A technology of vacuum pressure impregnation and resin, applied in the field of preparation of vacuum pressure impregnated resin, can solve the problems of short storage period, serious environmental pollution, polluted environment, etc., and achieve the effect of reducing operating temperature, simplifying process flow and excellent electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

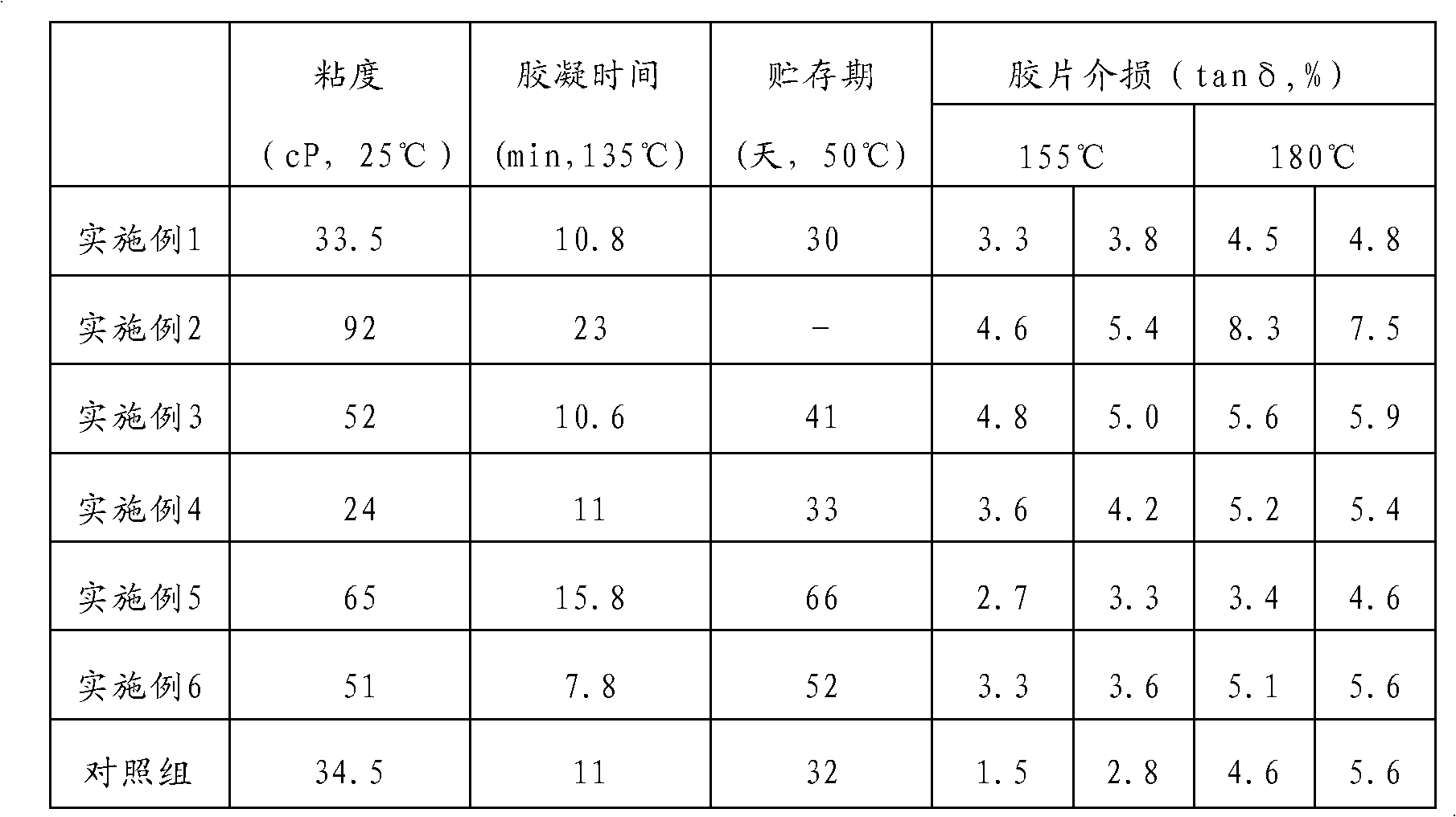

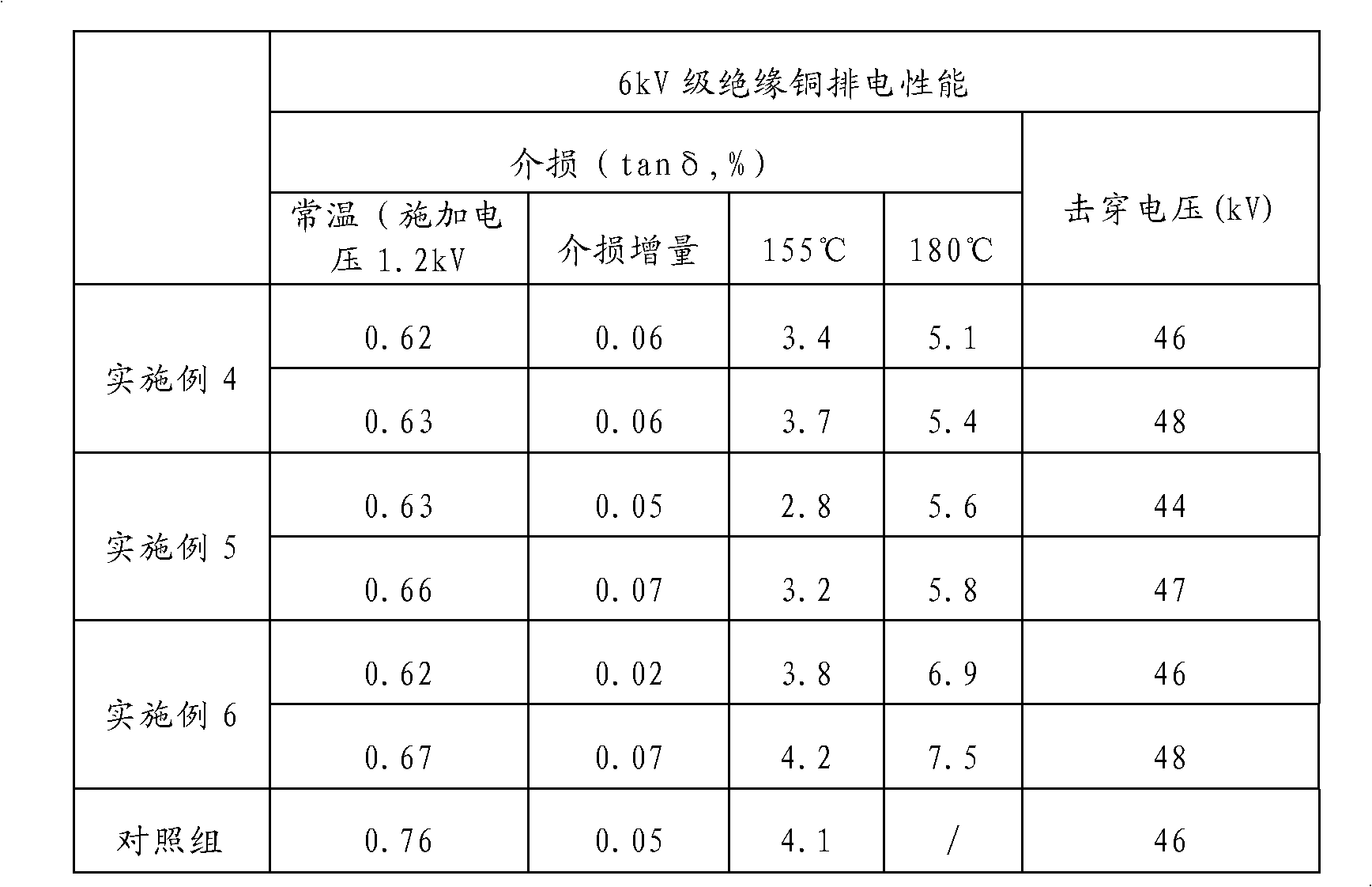

Examples

Embodiment 1

[0026] Embodiment 1 (method 1)

[0027] Heat 100 parts by weight of hydantoin epoxy and 30 parts by weight of acidic polyester resin to 100-110°C, stir evenly and maintain it for 0.5 hours, then add 0.1 parts by weight of hydroquinone, continue stirring for 0.5 hours, then cool down to 80°C, Add 319 parts by weight of methyl hexahydrophthalic anhydride, keep at this temperature for 20 minutes and then cool down to 60°C, then add glycidyl methacrylate dissolved in 0.1 parts by weight of chromium acetylacetonate and 0.4 parts by weight of dicumyl peroxide 270 parts by weight were stirred at 60°C for 0.5 hours to obtain a vacuum pressure impregnation resin.

Embodiment 2

[0028] Embodiment 2 (method 2)

[0029] Heat the mixture of 100 parts by weight of high-purity bisphenol A low-molecular epoxy and 5 parts by weight of maleic anhydride to 100-110°C, stir well and keep it for 0.5 hours, then cool down to 80°C, add 80 parts by weight of methylhexa hydrophthalic anhydride, stirred for 20 minutes. 2 parts by weight of dicumyl peroxide was added to 30 parts by weight of diallyl phthalate, and stirred at 110° C. for 1.5 hours. Then cool down to about 60°C and add 1 part by weight of p-tert-butylcatechol and 2 parts by weight of chromium acetylacetonate. After stirring for 0.5 hours, add the above-mentioned bisphenol A epoxy, maleic anhydride and methyl hexahydro to the mixture The mixture of phthalic anhydride was stirred at 60° C. for 0.5 hours to obtain a vacuum pressure impregnation resin.

Embodiment 3

[0030] Embodiment 3 (method 1)

[0031] Heat the mixture of 100 parts by weight of novolac epoxy and 10 parts by weight of acidic polyester resin to 100-110°C, stir evenly and maintain it for 0.5 hours, then cool to 80°C, add 175 parts by weight of methyl tetrahydrophthalic anhydride, at this temperature After stirring for 20 minutes, cool down to 60°C, add 100 parts by weight of 1,2-monoepoxy that dissolved 0.3 parts by weight of bis(2-phenylethoxy)dicarbonate and 0.1 parts by weight of chromium acetylacetonate - 4-Vinylcyclohexene, stirred at this temperature for 0.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com