Polyamide resin with low softening point and preparation method thereof

A technology of polyamide resin with low softening point, applied in adhesives, etc., can solve the problems of poor low temperature resistance and achieve good high and low temperature resistance and mechanical properties, low water absorption and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

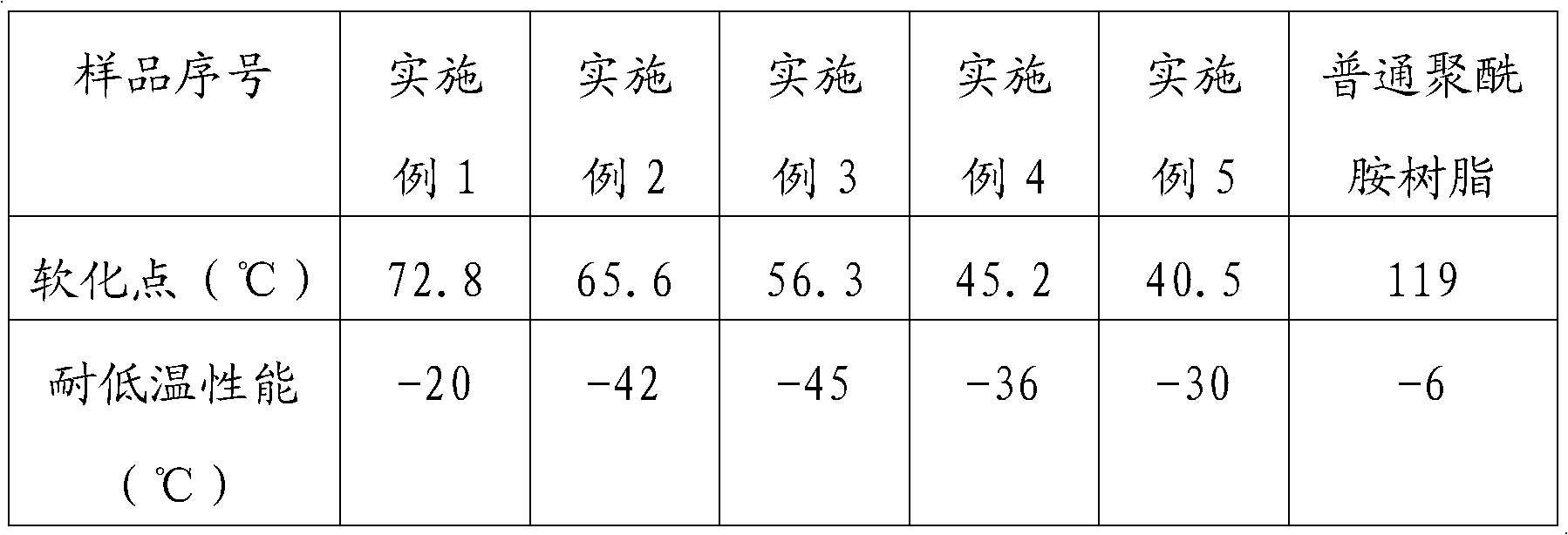

Examples

Embodiment 1

[0027] Add 173.00g of hydrogenated dimer acid, 35.89g of polyetheramine D-230, 1.8g of tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl)propionic acid]pentaerythritol ester, 1.0g propionic acid, and 8.99g ethylenediamine are packed in the constant-pressure dropping funnel, feed nitrogen and stir to start heating, and the temperature rises within 40 minutes. to 130°C, and at this temperature, slowly drop ethylenediamine, and the dropwise addition is completed within 40 minutes. At this time, the temperature rises to 140°C, and stirs at this temperature for 2 hours, and then slowly increases the temperature. There will be water evaporated, and the temperature will rise to 240°C within 3 hours, keep at this temperature for 2 hours, then use a vacuum pump to vacuum for 2 hours to a pressure of 100Pa, and finally discharge the material under the protection of nitrogen to obtain a light yellow rubber strip.

Embodiment 2

[0029] Add 160.10g of dimer acid, 33.77g of polyetheramine D-230, 56.30g of polyetheramine D-2000, 1.0g of tetra[β -(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 0.6g phosphite tris(2,4-di-tert-butylphenyl) ester, 1.40g propionic acid, and 6.77 Put ethylenediamine into a constant pressure dropping funnel, feed in nitrogen and stir to start heating, raise the temperature to 130°C within 60 minutes, and slowly add ethylenediamine dropwise at this temperature, and complete the dropwise addition within 60 minutes At this time, the temperature rises to 140°C, and stirs at this temperature for 2 hours, and then slowly raises the temperature. During this process, water will evaporate, and the temperature rises to 280°C within 3 hours, and is kept at this temperature for 5 hours. Then use a vacuum pump to evacuate for 3 hours to a pressure of 200 Pa, and finally discharge under the protection of nitrogen to obtain a light yellow rubber strip.

Embodiment 3

[0031] Add 149.80g of dimer acid, 63.30g of polyetheramine D-400, 52.77g of polyetheramine D-2000, 1.5g of tetra[β -(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 6.90g stearic acid, and 4.70g ethylenediamine are packed in the constant pressure dropping funnel, feed nitrogen and stir Start heating, raise the temperature to 120°C within 50 minutes, and slowly add ethylenediamine dropwise at this temperature, and complete the dropwise addition within 40 minutes, then the temperature rises to 130°C, and stir at this temperature for 2 hours, Then slowly raise the temperature, water will evaporate during this process, the temperature will rise to 220°C within 2 hours, keep at this temperature for 1 hour, then use a vacuum pump to evacuate for 3 hours to a pressure of 400Pa, and finally leave under the protection of nitrogen. material, a light yellow strip was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com