Quick blocking agent and preparation method thereof

A plugging agent, fast technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to realize fast plugging operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

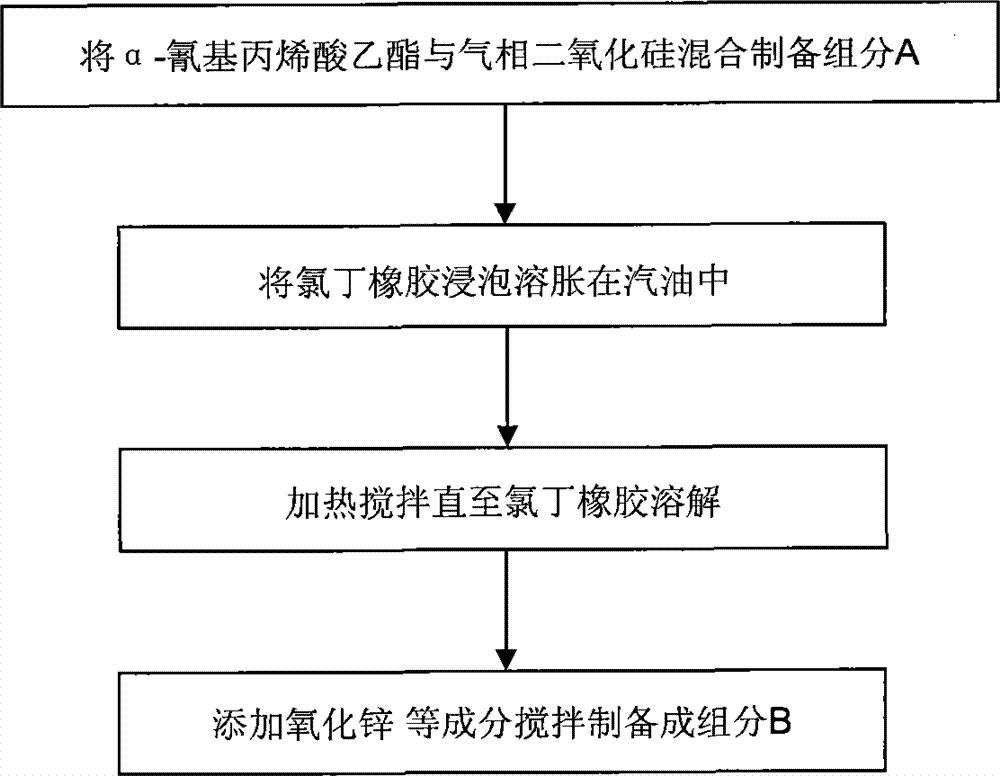

[0025] see figure 1 As shown, first take 80 parts by weight of ethyl α-cyanoacrylate and 5 parts by weight of fumed silica (molecular formula is SiO 2 , white fluffy powder, porous, non-toxic, tasteless, pollution-free, high temperature resistance, etc.) Stir and mix at room temperature to prepare component A, and keep it sealed for later use; then take 20 parts by weight of neoprene Put 20 parts by weight of gasoline into the container, soak and swell the chloroprene rubber, the soaking and swelling time is about 60 hours, so that the chloroprene rubber can achieve the best swelling effect, that is, the absorption effect is excellent; then the container is heated to 50° and stir until the neoprene is completely dissolved; then take 2.5 parts by weight of zinc oxide, 1 part by weight of aniline antioxidant, 2 parts by weight of magnesium oxide, 40 parts by weight of ethyl acetate, 10 parts by weight of ethane The solution and 5 parts by weight of carborundum were added into t...

Embodiment 2

[0030] The preparation method of this example is basically the same as that of Example 1, except that 90 parts by mass of ethyl α-cyanoacrylate and 5 parts by mass of fumed silica were mixed in an airtight container.

[0031] Component A and component B prepared in this example are rapidly mixed at a ratio of 37:62, which can be used for caulking. Its specific use method is as follows:

[0032] When encountering a seam that is not suitable for stirring, you can slightly combine the spare components A and B according to the above proportions into the same elastic material sharp-nosed injection container, and then quickly within 5 seconds. Shake the container and inject it into the crack within five seconds to complete the filling of the crack. What needs to be explained here is that if the injection is not completed within ten seconds, the plugging agent in the syringe will start to solidify.

[0033] After testing, using this plugging agent to add seam plugging, its curing t...

Embodiment 3

[0035] The preparation method of this example is basically the same as that of Example 1, except that 100 parts by mass of ethyl α-cyanoacrylate and 5 parts by mass of fumed silica are mixed in an airtight container.

[0036] Component A and component B prepared in this embodiment are rapidly mixed at a ratio of 37:62, which is suitable for rapid prototyping casting. Its specific use method is as follows:

[0037] When making the real sample of the mechanical model, the spare components A and B are slightly combined in the model cavity according to the above ratio, and the air intake in the model cavity is ensured, and then the model cavity is placed in vibration The platform is fixed, and the total volume of the above two components is 40% of the volume of the model cavity. Through the vibration of the vibrating platform, the two components and the moisture in the air are melted together, quickly combined and expanded to fill the model cavity, and the excess part overflows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com