Method for synthesizing starch acetate

A technology of starch acetate and synthesis method, which is applied in the field of food biochemical industry, can solve the problems of high reaction temperature, achieve high reaction efficiency, mild conditions, and increase the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

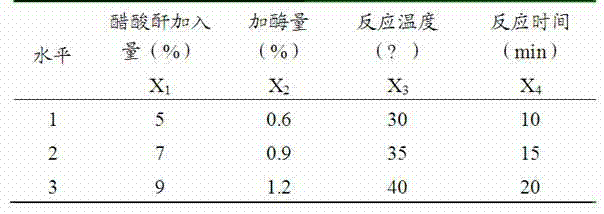

Method used

Image

Examples

Embodiment 1

[0029] (1) Starch pretreatment Weigh 60g of starch into 200ml of water, swell by absorbing water at 40°C for 20 minutes, and filter.

[0030] (2) Esterification Add 90ml of water to the treated starch to prepare 40% starch milk, then add 0.36g of lipase, heat to a constant temperature of 30°C, add 5% acetic anhydride, and stir in a water bath at a constant temperature of 30°C for 10 minutes , the stirring speed was 150rpm to obtain starch acetate, and the degree of substitution of starch acetate reached 0.0302 after determination.

Embodiment 2

[0032] (1) Starch pretreatment Weigh 60g of starch into 200ml of water, swell by absorbing water at 40°C for 20 minutes, and filter.

[0033] (2) Esterification Add 90ml of water to the treated starch to make 40% starch milk, then add 0.54g of lipase, heat to 40°C constant temperature, add 9% acetic anhydride, stir in 40°C constant temperature water bath for 10min , the stirring speed was 150rpm to obtain starch acetate, and the degree of substitution of starch acetate reached 0.0426 after determination.

Embodiment 3

[0035] (1) Starch pretreatment Weigh 60g of starch into 200ml of water, swell by absorbing water at 40°C for 20 minutes, and filter.

[0036] (2) Esterification Add 90ml of water to the treated starch to prepare 40% starch milk, then add 0.36g of lipase, heat to a constant temperature of 35°C, add 9% of acetic anhydride, stir in a constant temperature water bath at 35°C for 15 minutes , the stirring speed was 150rpm, and starch acetate was obtained, and the degree of substitution of starch acetate reached 0.0733.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com