System for efficiently cracking electronic wastes based on strong plasma

A technology of electronic waste and plasma, applied in the direction of plasma, electrical components, electrical program control, etc., to achieve the effect of improving power conversion efficiency and inverter frequency, improving working conditions, and uniform parameter gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the implementation of the present invention is not limited thereto.

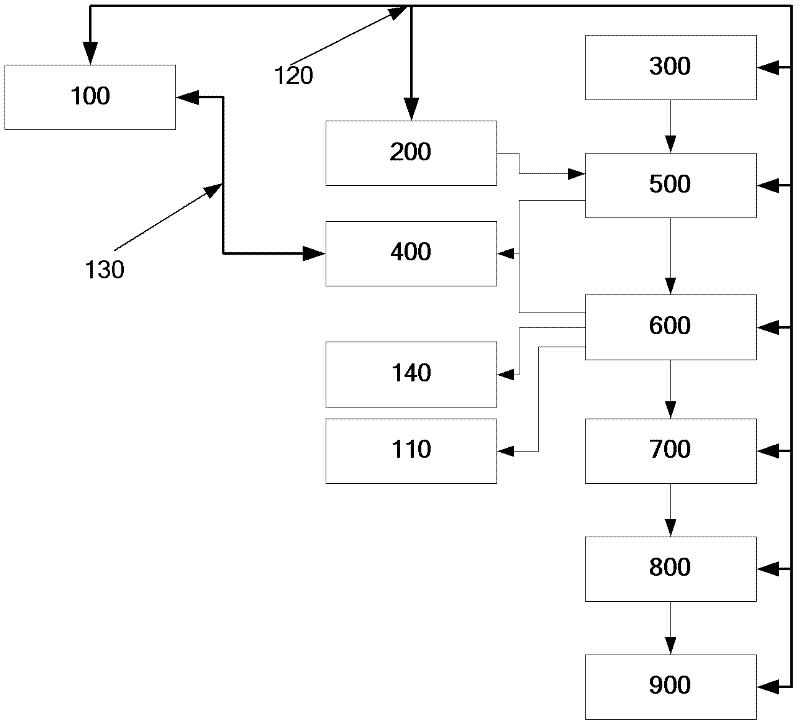

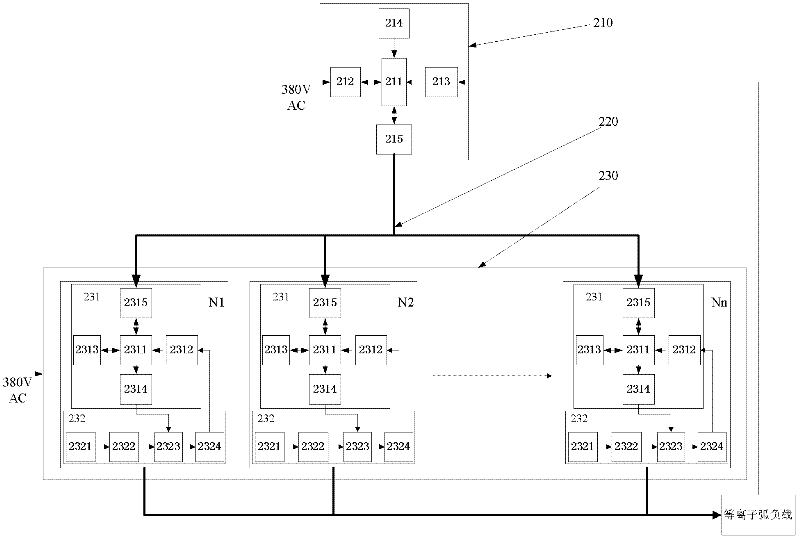

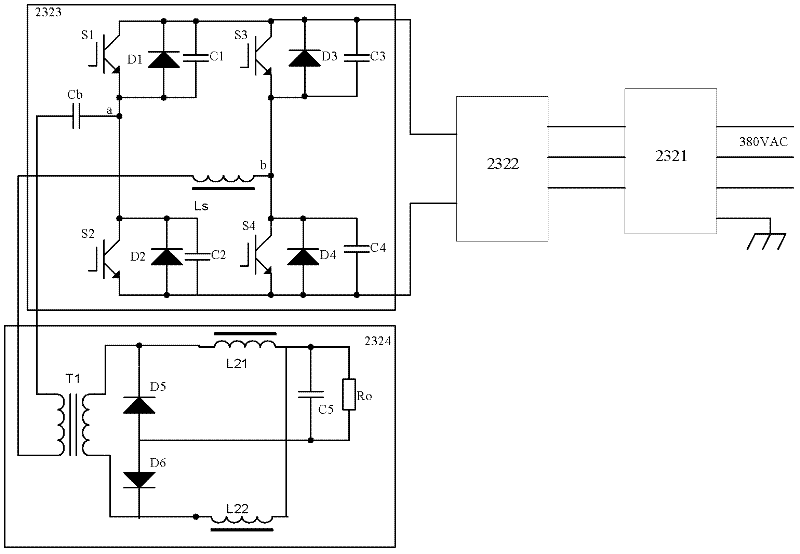

[0037] like figure 1 As shown, the high-efficiency pyrolysis system of electronic waste based on strong plasma in the present invention consists of a computer comprehensive management system 100, a plasma power supply 200, an electromagnetic generator 300, a plasma generator 500, a digital visual monitoring system 400, and a pyrolysis furnace 600. Absorption tower 700, bag filter 800, activated carbon adsorption tower 900, vitreous body discharge tank 140, metal block shaping tank 110, iCAN network 120, and TCP / IP network 130 constitute. Plasma power supply 200, electromagnetic generator 300, plasma generator 500, pyrolysis furnace 600, absorption tower 700, bag filter 800 and activated carbon adsorption tower 900 are all connected to the computer integrated management sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com