Travelling wave tube collector assembly and assembly process thereof

An assembly process and collector technology, which is applied in the field of traveling wave tube collector assembly and its assembly process, can solve the difficulty of ensuring the assembly quality of the traveling wave tube collector assembly, the difficulty in ensuring the assembly quality of the traveling wave tube, and the impact on the traveling wave tube assembly. Assembling quality and other issues, to achieve the effect of reducing aging time, easy processing quality, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

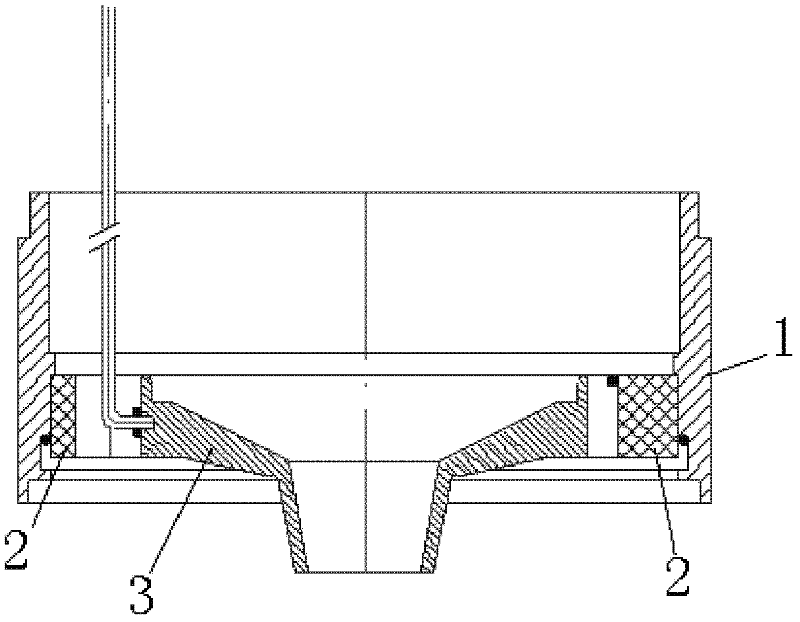

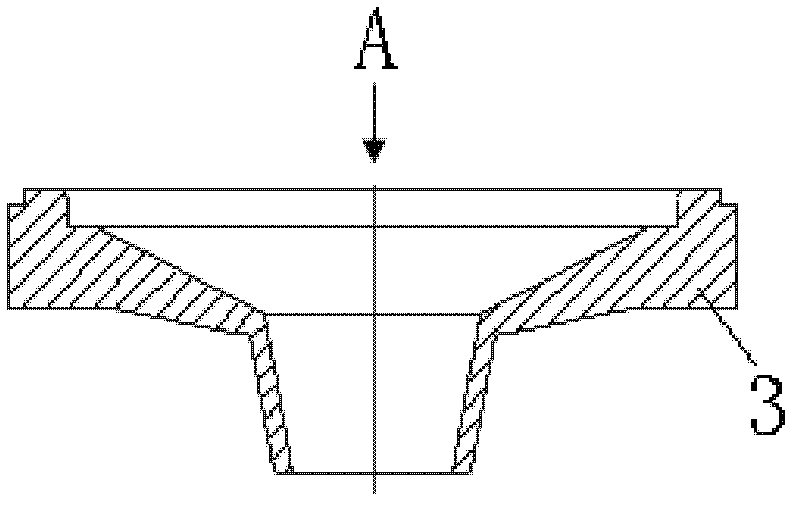

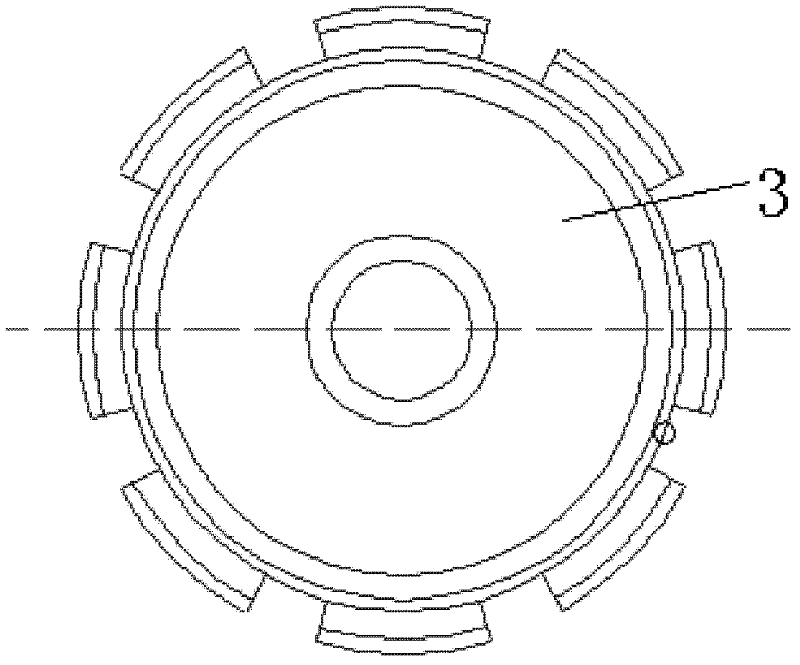

[0033] like Figure 1 to Figure 3 As shown, the collector assembly of the traveling wave tube includes a collector inner core 3 and a collector sleeve 1, the collector inner core 3 is arranged inside the collector sleeve 1, and the collector inner core 3 and the collector sleeve Insulation ceramics 2 are arranged between 1; the collection-level inner core 3 is made of molybdenum-copper material.

[0034] One side of the insulating ceramic 2 is brazed with the collector inner core 3; the other side of the insulating ceramic 2 is brazed with the collector sleeve 1; the brazing solder is palladium-based solder, and the currently used PAgCu20 solder is mainly purchased from the market. Generally purchased from Guiyan Platinum Co., Ltd.

[0035] The advantages of the collector core made of mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com