Method and device for preparing make-up water for power station boilers from municipal reclaimed water

A technology for power plant boilers and reclaimed water, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effects of large hydraulic load, low operating cost, and large volumetric load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

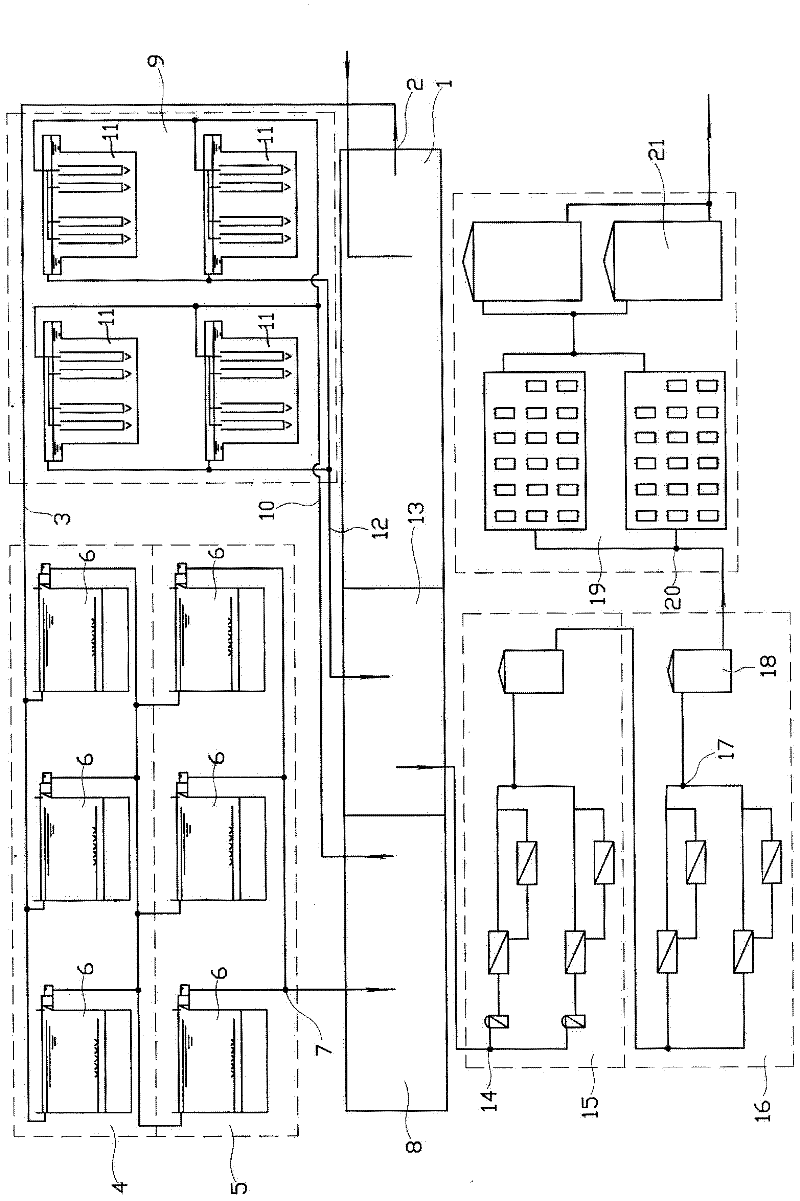

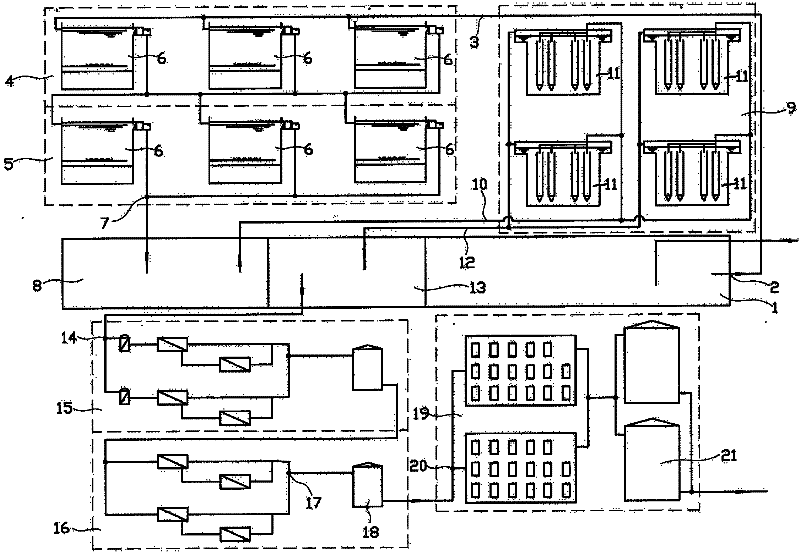

Image

Examples

Embodiment

[0032] The method for making power plant boiler feed water with urban reclaimed water has the following steps:

[0033] (1) The urban regenerated water is sent from the regulating tank to the biological aerated filter, and the urban regenerated water is treated by the front and rear two-stage biological aerated filter,

[0034] The main function of biological aerated filter is to remove organic matter and ammonia nitrogen in urban reclaimed water, and at the same time remove the turbidity of urban regenerated water. After passing through biological aerated filter, the water quality stability of the pretreated water can be improved and become It is not easy to be corrupted and smelly, and the COD value, BOD value and ammonia nitrogen of the sewage are greatly reduced to meet the requirements of the subsequent process. The urban reclaimed water is treated by a two-stage biological aerated filter to obtain clear pretreated water, and the pretreated water enters the pretreatment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com