Preparation method of carbon nano tube/polymer/semiconductor nano particle composite material

A technology of nanocomposite materials and carbon nanotubes, applied in shielding, nuclear engineering, reactors, etc., to achieve the effects of structural integrity protection, enhanced dispersion, and low raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

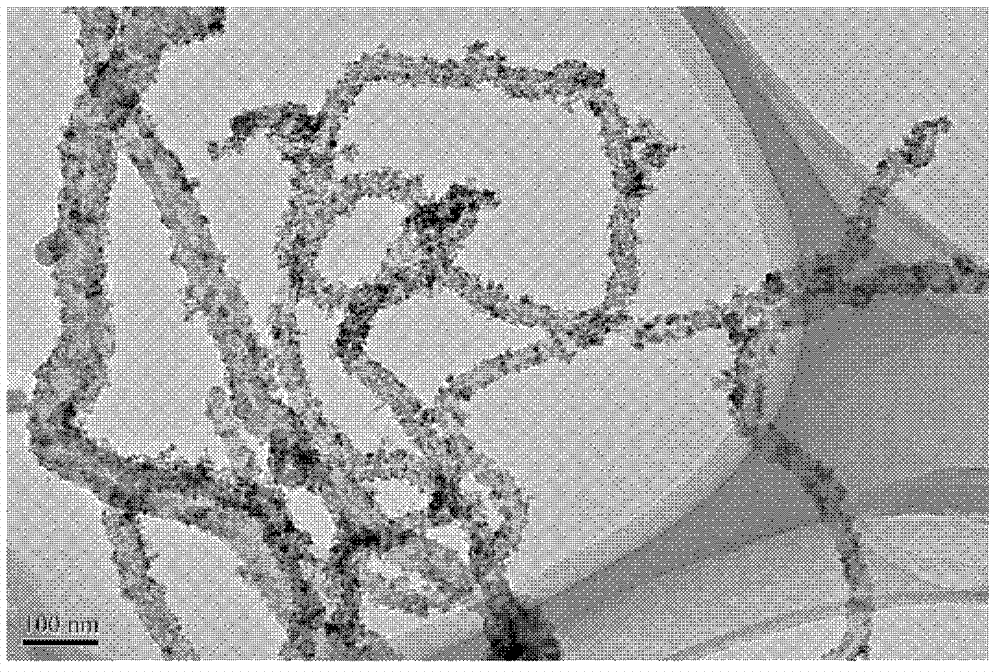

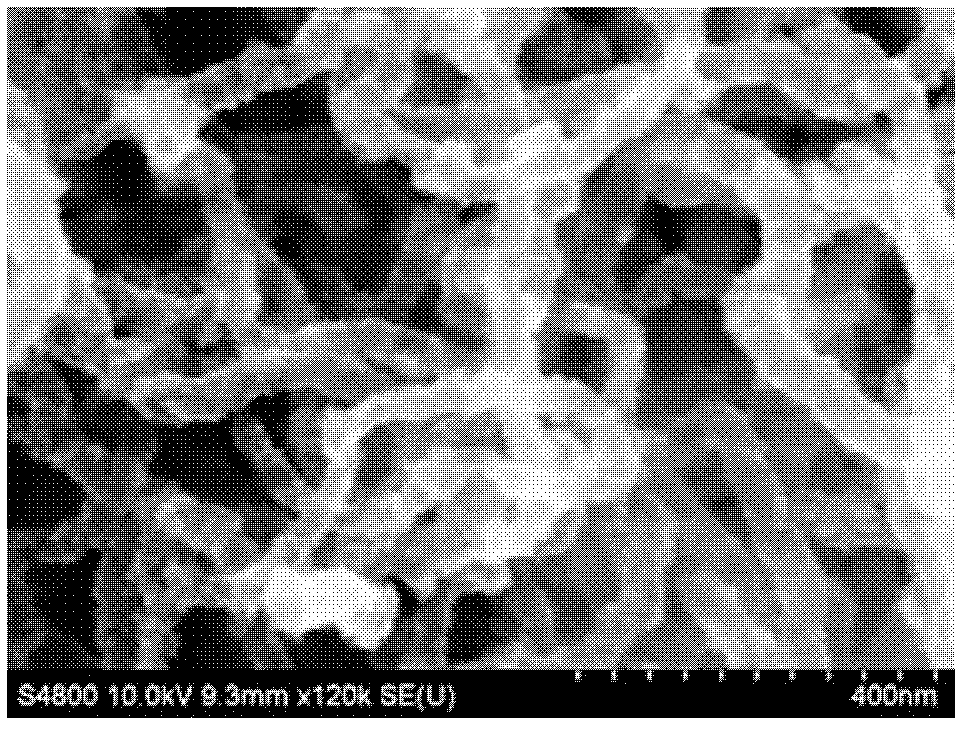

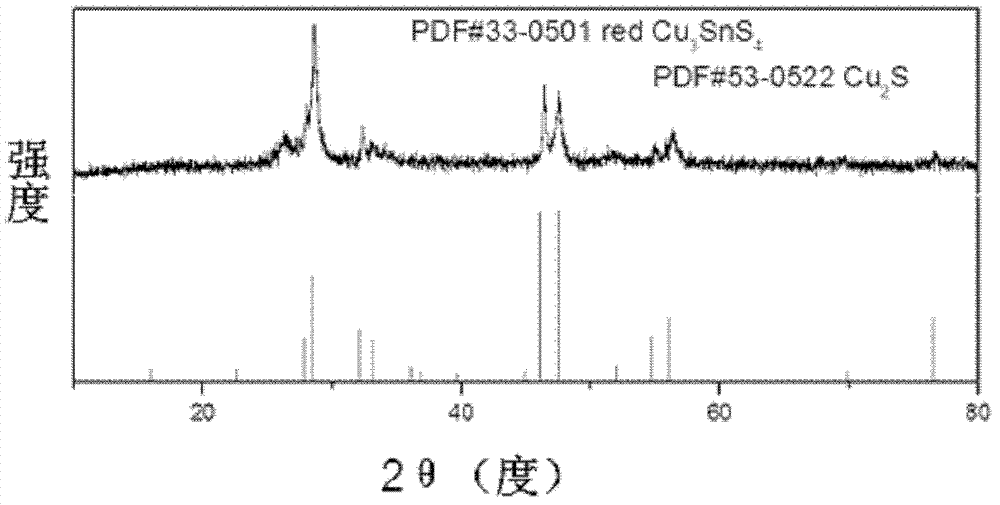

Image

Examples

Embodiment 1

[0028] a) Dissolve 30 mg of sodium polystyrene sulfonate in 30 mL of ethanol;

[0029] b) Add 30 mg of multi-walled carbon nanotubes to the above solution and ultrasonicate for 2 hours;

[0030] c) Centrifuge the solution obtained in b) and wash it with ethanol 6 times until the excess sodium polystyrene sulfonate is washed away;

[0031] d) Disperse the centrifugal sediment obtained above in 30 mL ethanol, sonicate for 2 h, and add 0.9 mmol CuCl to it 2 ·2H 2 O and 0.3mmol SnCl 2 ·2H 2 O, CuCl used 2 ·2H 2 O and SnCl 2 ·2H 2 The ratio of the amount of O substance is 3:1. Magnetic stirring for 10min at room temperature to make Cu 2+ And Sn 2+ Fully adsorbed on carbon nanotubes;

[0032] e) Add 30mL thiourea ethanol solution (concentration 3mg / ml, thiourea 1.2mmol) dropwise to the solution of d), continue to stir for 10min, transfer the solution to the reaction kettle, and react at 200℃ for 12h;

[0033] f) Cool to room temperature, centrifuge at 6000 rpm for 10 minutes, wash with disti...

Embodiment 2

[0038] a) Dissolve 30 mg of sodium polystyrene sulfonate in 30 mL of ethanol;

[0039] b) Add 30 mg of multi-walled carbon nanotubes to the above solution and ultrasonicate for 2 hours;

[0040] c) Centrifuge the solution obtained in b) and wash it with ethanol 6 times until the excess sodium polystyrene sulfonate is washed away;

[0041] d) Disperse the centrifugal sediment obtained above in 30 mL ethanol, sonicate for 2 hours, and add 0.6 mmol CuCl to it 2 ·2H 2 O and 0.6mmol SnCl 2 ·2H 2 O, CuCl used 2 ·2H 2 O and SnCl 2 ·2H 2 The ratio of the amount of O substance is 1:1. Magnetic stirring for 10min at room temperature to make Cu 2+ And Sn 2+ Fully adsorbed on carbon nanotubes;

[0042] e) Add 30mL thiourea ethanol solution (concentration 3mg / ml, thiourea 1.2mmol) dropwise to the solution of d), continue to stir for 10min, transfer the solution to the reaction kettle, and react at 200℃ for 12h;

[0043] f) Cool to room temperature, centrifuge at 6000 rpm for 10 minutes, wash with d...

Embodiment 3

[0050] a) Dissolve 30 mg of sodium polystyrene sulfonate in 30 mL of ethanol;

[0051] b) Add 30 mg of multi-walled carbon nanotubes to the above solution and ultrasonicate for 2 hours;

[0052] c) Centrifuge the solution obtained in b) and wash it with ethanol 6 times until the excess sodium polystyrene sulfonate is washed away;

[0053] d) Disperse the centrifugal sediment obtained above in 30 mL ethanol, sonicate for 2 h, and add 0.3 mmol CuCl to it 2 ·2H 2 O and 0.9mmol SnCl 2 ·2H 2 O, CuCl used 2 ·2H 2 O and SnCl 2 ·2H 2 The ratio of the amount of O substance is 1:3. Magnetic stirring for 10min at room temperature to make Cu 2+ And Sn 2+ Fully adsorbed on carbon nanotubes;

[0054] e) Add 30mL thiourea ethanol solution (concentration 3mg / ml, thiourea 1.2mmol) dropwise to the solution of d), continue to stir for 10min, transfer the solution to the reaction kettle, and react at 200℃ for 12h;

[0055] f) Cool to room temperature, centrifuge at 6000 rpm for 10 minutes, wash with disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com