High-elastic modified asphalt and preparation method thereof

A technology of modified asphalt and high elasticity, which can be applied to cohesive pavement paved on site, building components, building insulation materials, etc. It can solve the problems of unsuitable asphalt mixture and cracking of asphalt mixture, and improve the resistance to low temperature deformation ability and fatigue resistance, improved fatigue life, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Heat 1000g of Zhonghai 70# base asphalt to 180°C, add 40g of SBS, 20g of SBR (high polymer), 4g of p-phenylenediamine anti-aging agent (anti-aging agent), 50g of diphenyloctyl phosphate (plasticizer), 30g Dibutyl phthalate (plasticizer), swell for 60 minutes, then use a colloid mill to shear at high speed twice, finally add 3g of sulfur, and stir at high speed for 3 hours.

[0024] Ordinary modified asphalt modification process and formula is to raise the temperature of 1000g Zhonghai 70# base asphalt to 180℃, add 60gSBS, swell for 60 minutes, then use a colloid mill to shear at high speed twice, finally add 3g sulfur, and stir at high speed for 3 hours have to.

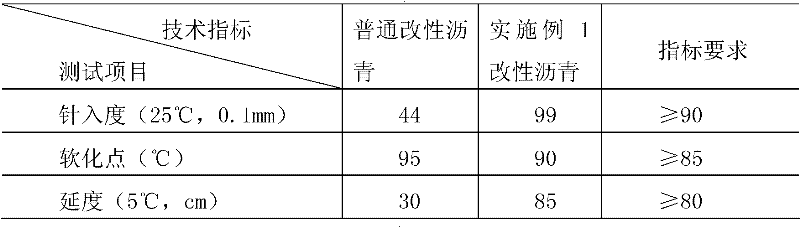

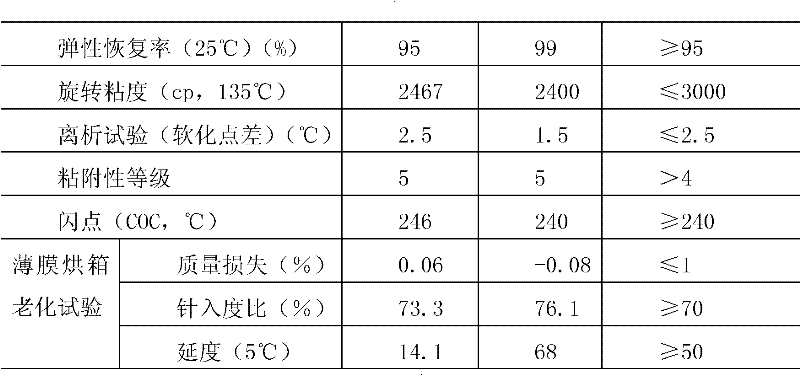

[0025] Table 1 Comparison table of various indicators between ordinary modified asphalt and modified asphalt in Example 1

[0026]

[0027]

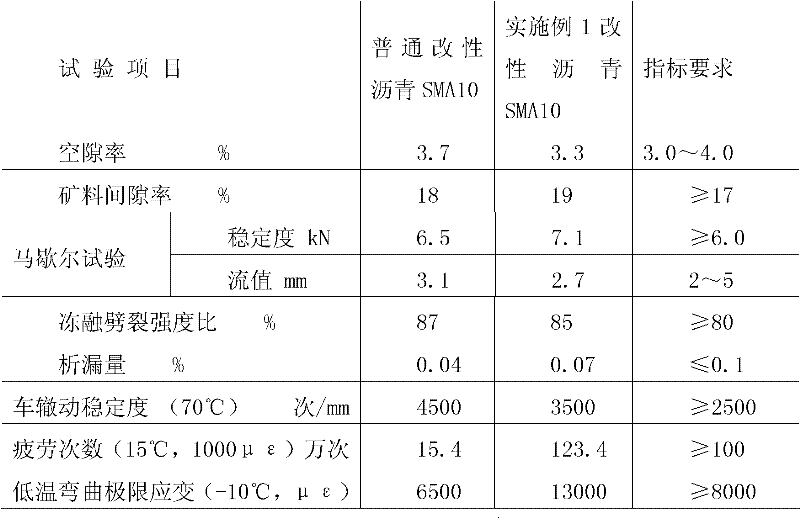

[0028] Table 2 Comparison table of performance of ordinary modified asphalt and modified asphalt in Example 1 for steel bridge deck pavement surface layer SMA10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com