Method for printing disordered micro nanofibers into ordered fiber array

A technology of micro-nano fibers and disordered arrangement, applied in textiles and papermaking, etc., can solve the problems of collection screen limitation, inability to collect ordered fibers, and small area of ordered fibers, achieving a wide range, good printing effect, and application scope wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

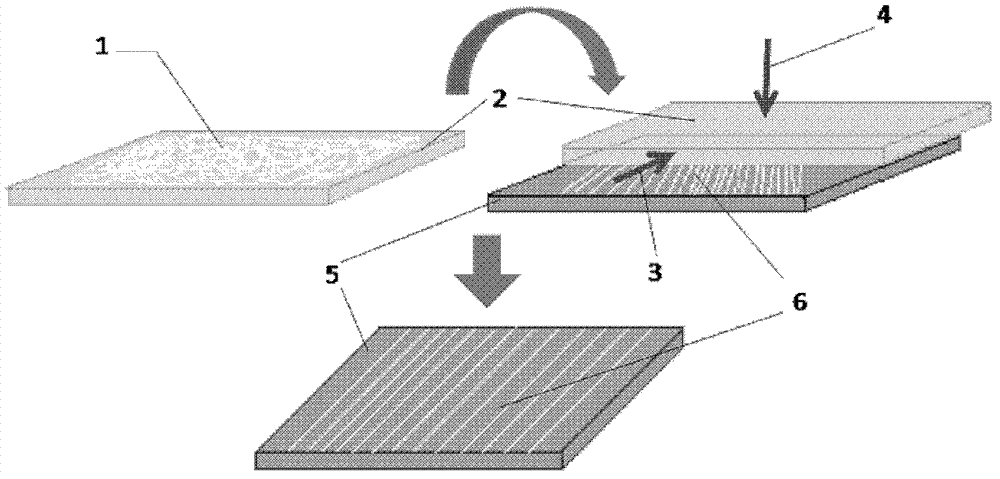

[0009] Further description will be given below through the embodiments and in conjunction with the accompanying drawings.

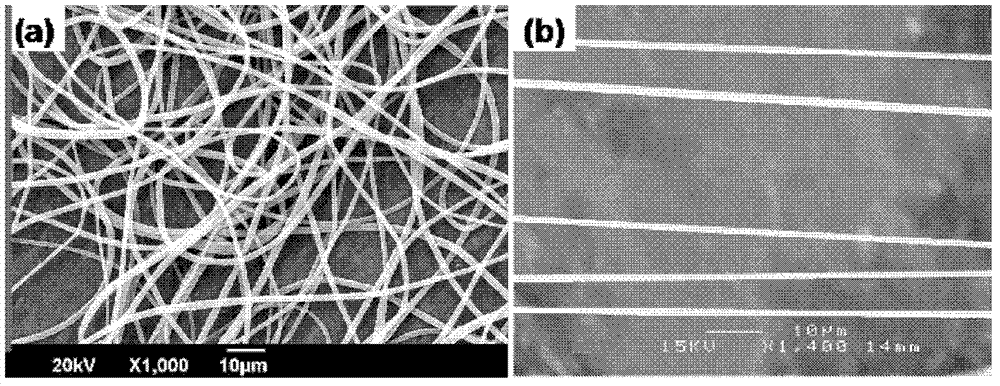

[0010] In this example, a conventional electrospinning device was used, and the selected spinning solution was a polyvinylidene fluoride (PVDF) solution with a mass fraction of 20%. First, 3.1 grams of PVDF particles were slowly added to 12.4 grams of In a mixed solution of dimethyl sulfoxide (DMSO) and acetone (the mass ratio of DMSO and acetone is 1:1, 6.2 grams each); heat the mixed solution to 40-60°C for 1 hour with magnetic stirring , let it stand for half an hour to get a PVDF electrospinning precursor solution with a mass fraction of 20%; then inject the PVDF electrospinning precursor solution with a mass fraction of 20% into a syringe with a needle tip connected to the positive electrode of a high-voltage power supply, and place it horizontally The silicon wafer is used as the collecting substrate 2, the spinning voltage provided by the high-volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com