High-sensitivity micro-nano optical fiber refractive index sensor and preparation method thereof

A technology of refractive index sensor and micro-nano optical fiber, which is applied to the measurement of phase influence characteristics, etc., can solve the problems of fiber structure damage, expensive femtosecond laser, and low sensitivity, and achieve the effect of fast response, light weight, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

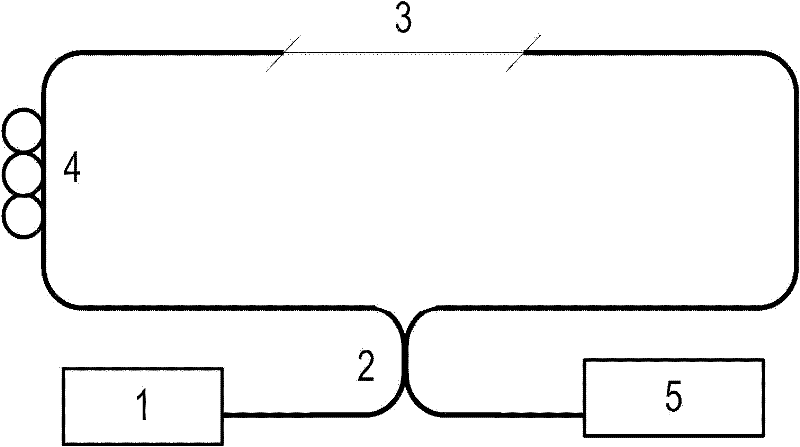

[0033] Such as figure 1 As shown, a high-sensitivity micro-nano optical fiber refractive index sensor includes a broadband light source 1 sequentially connected along the optical transmission path, a fiber coupler 2 with a splitting ratio of 50%:50%, a birefringent micro-nano optical fiber 3, a first polarization control device 4 and spectrum analyzer 5, wherein fiber coupler 2, birefringent micro-nano fiber 3 and first polarization controller 4 form a fiber optic loop mirror; after the light emitted by broadband light source 1 enters the fiber optic loop mirror through fiber coupler 2, Two light beams propagating in opposite directions are formed, one of which passes through the first polarization controller 4 and the birefringent micro-nano fiber 3 in sequence, and the other passes through the birefringent micro-nano fiber 3 and the first polarization controller 4 in sequence. The beam of light generates a polarization phase difference. By adjusting the first polarization co...

Embodiment 2

[0038] The high-sensitivity micro-nano optical fiber refractive index sensor of the above-mentioned embodiment 1 can be improved as follows, such as Figure 5 Shown is the modified refractive index sensor, with figure 1 The difference is that a second polarization controller 12 and a polarization-maintaining fiber 13 are sequentially connected to one side of the micro-nano fiber through a standard fiber. Adjusting the second polarization controller 12 can adjust the density of the interference spectrum. We adjust the interference spectrum to a sparse state, corresponding to the situation where two birefringent optical fibers cause the polarization phase difference to be subtracted, as shown in equation (3) below, At the same time, the first polarization controller 4 is adjusted to enhance the extinction ratio of the interference spectrum for easy measurement.

[0039] Figure 6 The relationship between the wavelength and the refractive index corresponding to the position of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com