High-efficient four solar cell and manufacturing method thereof

A technology for solar cells and manufacturing methods, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as current recombination loss, complex post-processing, and lower efficiency, so as to reduce dislocation density, broaden spectral absorption range, and high crystallinity. The effect of grid quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

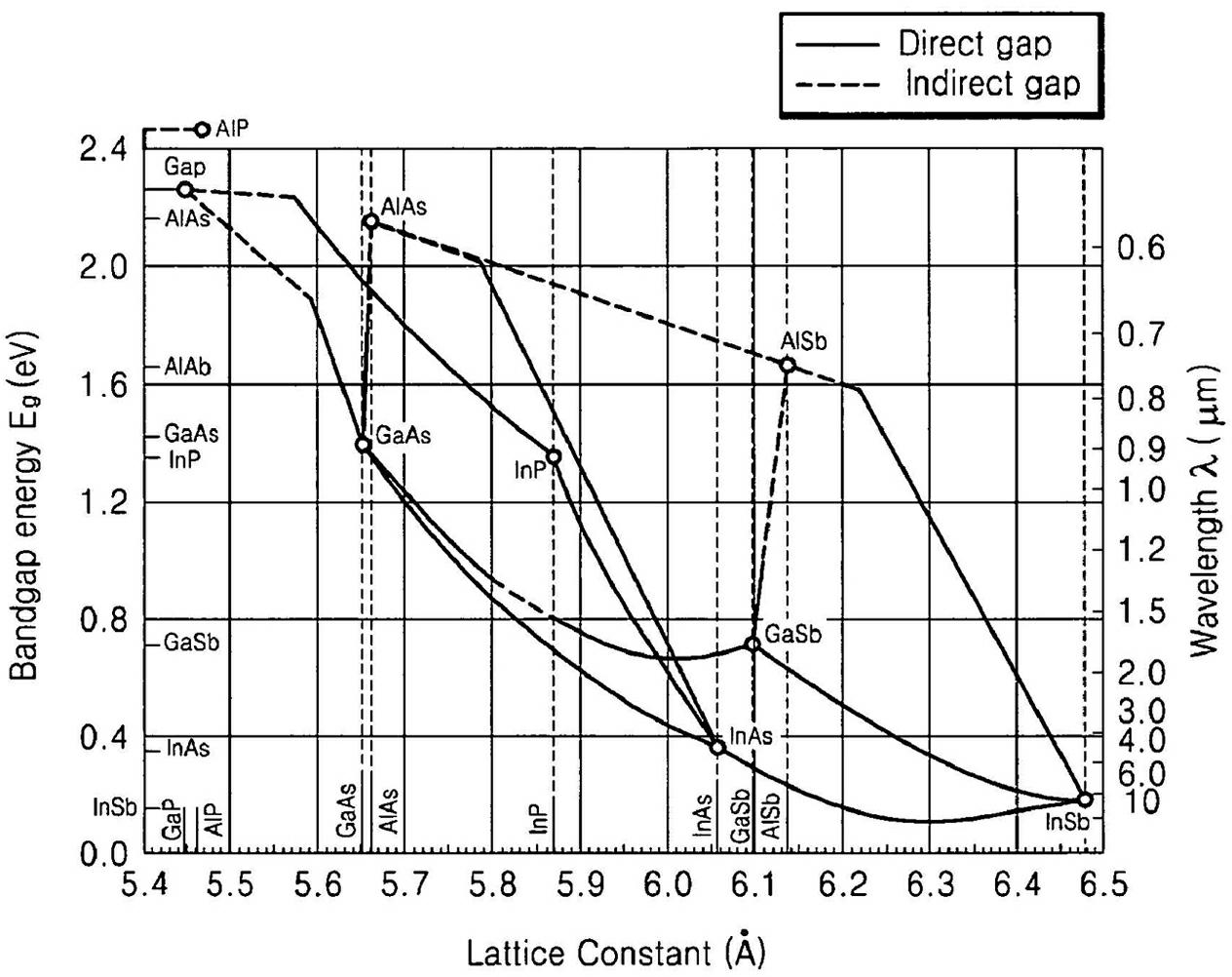

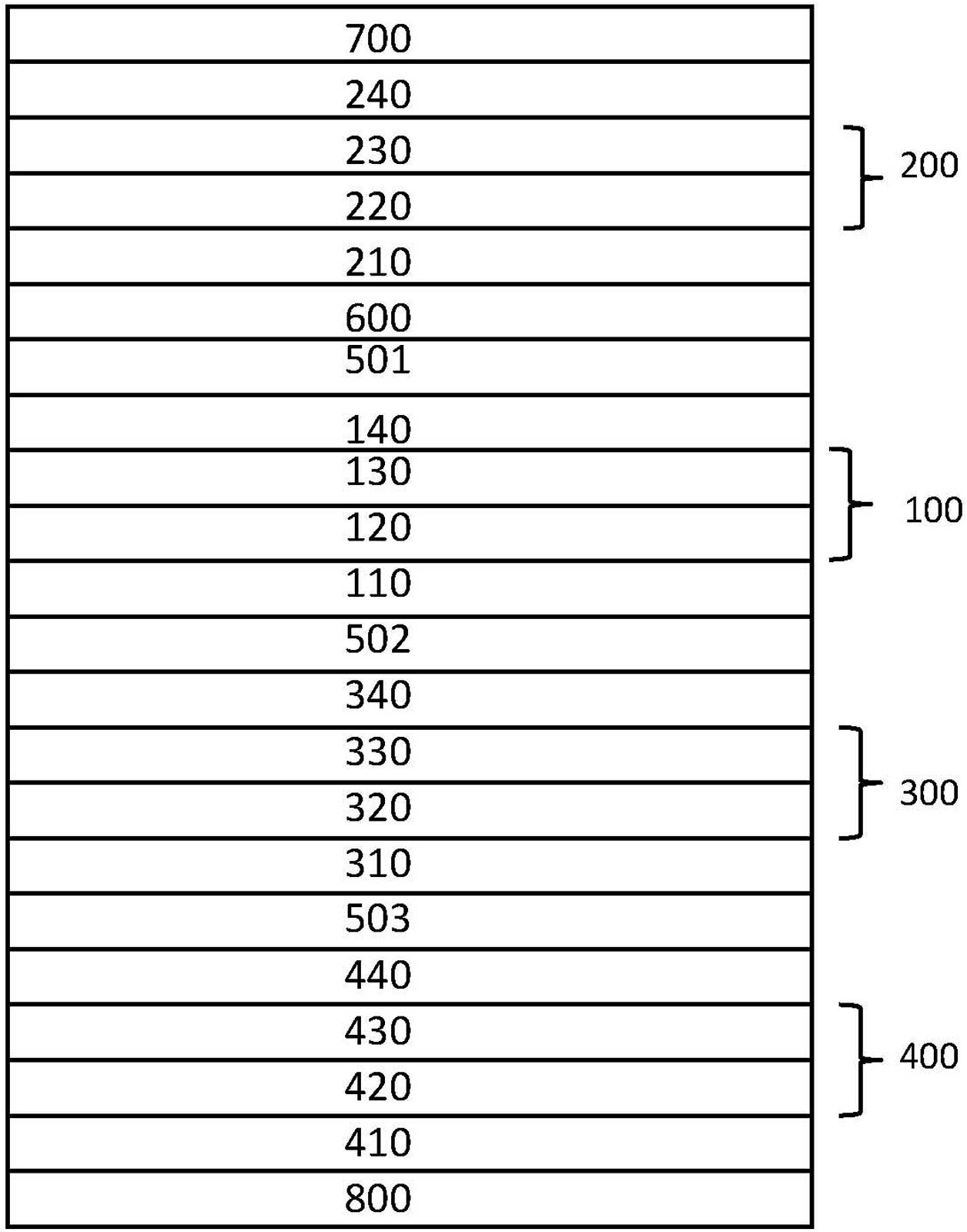

[0042] Such as figure 1 As shown, the structure of a high-efficiency four-junction solar cell includes a first sub-cell 100, a second sub-cell 200, a third sub-cell 300, and a fourth sub-cell 400, and tunnel junctions 501 and 502 are used between each junction cell. , 503 connection. Wherein, the first sub-cell 100 uses the growth substrate 001 itself as the base region 120, and implants n-type ions into the front surface of the p-type substrate to form the emitter region 130, thereby forming the first sub-cell. The arrangement order of the four-junction sub-battery from bottom to top is: the fourth sub-battery, the third sub-battery, the first sub-battery, and the second sub-battery.

[0043] The first sub-cell 100 uses the growth substrate 001 itself as the base region 120, implants n-type ions into the front of the p-type substrate to form the emitter region 130, and constitutes the first sub-cell with a band gap of 1.3-1.5 eV.

[0044] The growth substrate 001 is polishe...

Embodiment 2

[0056] This embodiment is a manufacturing process of a high-power concentrating multi-junction solar cell described in Example 1, which includes the formation process of the sub-cells 100, 200, 300, 400 and layers between the sub-cells.

[0057] The lattice constant and electrical properties in the semiconductor structure are controlled according to appropriate growth temperature and time and by using appropriate chemical compositions and dopants. Vapor deposition methods such as MOCVD and MBE can be used, but MOCVD is preferred as the growth technique of the present invention.

[0058] Concrete preparation process comprises the following steps:

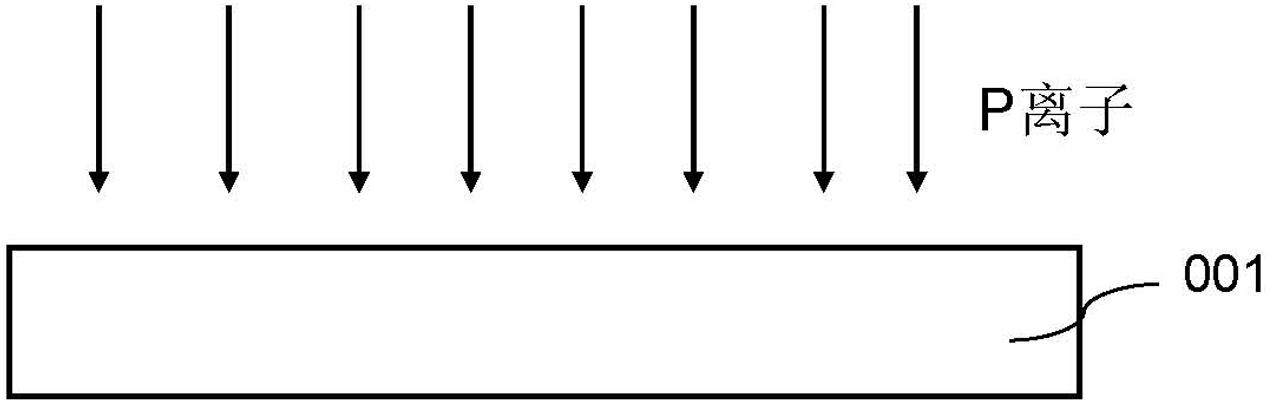

[0059] In the first step, a double-sided polished substrate 001 is provided. In this embodiment, a double-sided polished InP substrate with a p-type thickness of 200 microns is selected, and its doping concentration is 2×10 17 cm -3 ~5×10 17 cm -3 .

[0060] In the next step, the first sub-cell 100 is formed, the bandgap of whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com