Manufacturing method of flat-type avalanche diode detector used for detecting single photon

An avalanche diode, single-photon detection technology, applied in sustainable manufacturing/processing, semiconductor devices, climate sustainability, etc., can solve problems such as breakdown, affecting detector performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

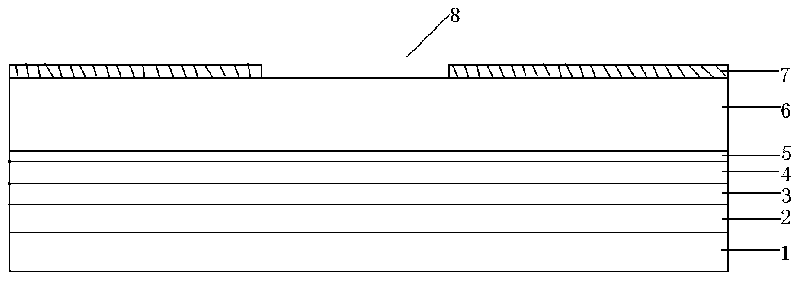

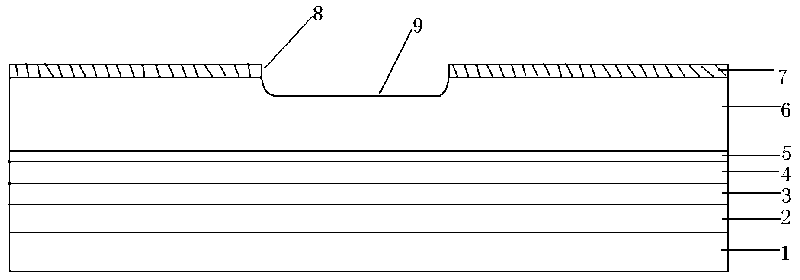

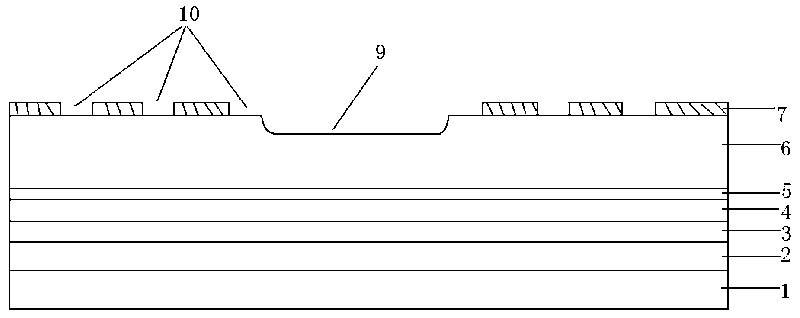

[0029] see Figure 1 to Figure 11 As shown, the present invention provides a method for manufacturing a planar avalanche diode detector that can be used for single photon detection, comprising the following steps:

[0030] Step 1: growing an InP buffer layer 2, an InGaAs absorption layer 3, an InGaAsP graded layer 4, an N-type InP charge layer 5 and an InP cap layer 6 sequentially on an N-type InP substrate 1;

[0031] Step 2: grow on the InP cap layer 6 with a thickness of SiO 2 protective layer 7;

[0032] Step 3: On SiO 2 A circular window 8 is photoetched in the middle of the protective layer 7, and the etching depth reaches the surface of the InP cap layer 6;

[0033] Step 4: Corrode the InP cap layer 6 in the circular window 8 by wet etching to form a circular pit 9, and the composition of the wet etching solution is Br 2 :HBr:H 2 O=1:25:80;

[0034] Step 5: SiO Around Circular Window 8 2 The window 10 of the protection ring is engraved on the protection layer 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com