Intelligent anti-icing deicing system and method for high-voltage transmission line

A high-voltage transmission line and transmission line technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of staying, difficult to grasp the deicing period, and unable to effectively prevent line jumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

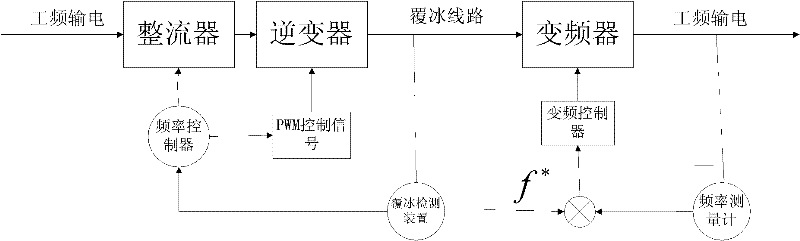

[0063] figure 1 It is a closed-loop control system for deicing AC power transmission, which includes an AC up-conversion module installed at the front end of the ice-coated line; an AC down-frequency module installed at the rear end of the ice-coated line; The frequency measuring meter at the output end of the frequency reducing module; receiving the signal sent by the ice detection device as a start signal to control the AC frequency increasing control module of the AC frequency increasing module; and receiving the frequency measuring meter signal as a feedback signal to control the AC frequency reducing of the AC frequency reducing module control module. The high-voltage transmission line is an AC transmission line, the AC up-conversion module is a rectifier and an inverter connected in sequence, and the AC up-conversion control module is a frequency controller. The AC frequency reduction module is a frequency converter, and the AC frequency reduction control module is a f...

Embodiment 2

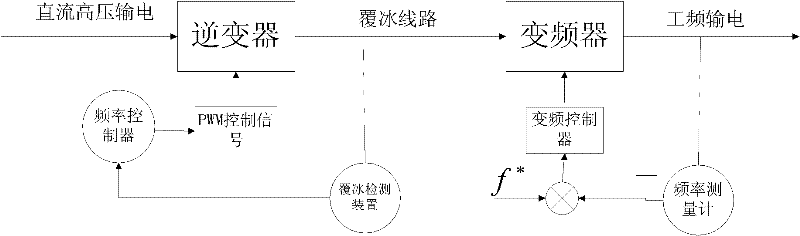

[0075] The basic principle of this embodiment is the same as that of Embodiment 1, the difference is that: the high-voltage transmission line is a DC transmission line, and the AC up-conversion module is an inverter, which directly converts high-voltage direct current into high-frequency alternating current, such as figure 2 shown. For the line after the ice-covered line, it should be analyzed according to the specific situation: 1. If the power frequency AC transmission is sufficient after deicing, the AC frequency reduction module will output AC power to continue the power transmission; 2. If DC power transmission is required after deicing, then Adding a rectifier after the AC frequency reduction module converts AC to DC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com