Curing device and warm water curing method for concrete baking-free bricks

A technology for non-burning bricks and concrete, applied in ceramic molding machines, manufacturing tools, etc., to achieve the effect of reducing labor intensity, reducing costs, and shortening the time required for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

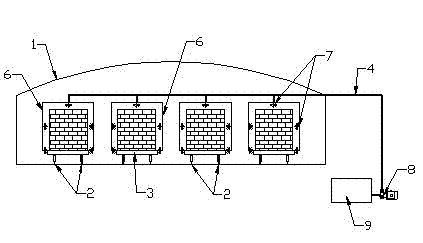

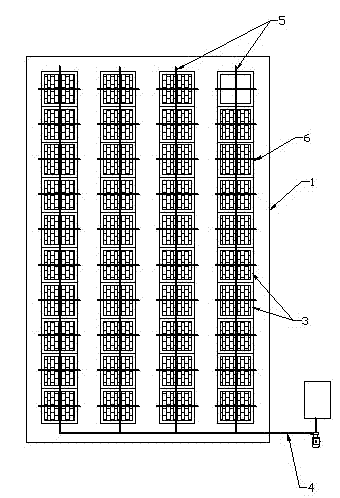

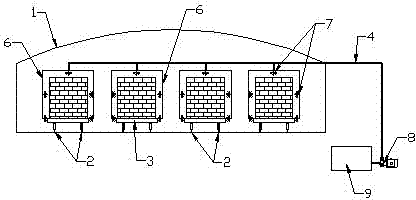

[0017] As shown in the figure, the concrete unburned brick maintenance device of the present invention is a maintenance workshop 1, a multi-row track 2 located in the maintenance workshop, a kiln car arranged on the track and movable along the track 3, a spray system; the spray system It includes a main water pipe 4 connected to a water reservoir 9 through a water pump 8, and a plurality of branch water pipes 5 located above the track and extending along the track. The branch water pipes 5 are connected to the main water pipe 4; Spray pipes 6, each set of spray pipes are provided with atomizing nozzles 7 located on both sides and above the kiln car 3.

[0018] The embodiment of the warm water maintenance method for concrete unburned bricks of the present invention is: divide the maintenance process of brick adobes into two stages, the first stage is to arrange the pressed brick adobes on the kiln car and enter the above-mentioned concrete unburned brick maintenance device, spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com