Corrosion and scale inhibitor for reuse of reclaimed water from production wastewater as circulating cooling water

A technology of circulating cooling water and corrosion and scale inhibitor, applied in the field of corrosion and scale inhibitor, can solve the problems of shutdown equipment, inconsistency, damage, etc., and achieve good scale inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

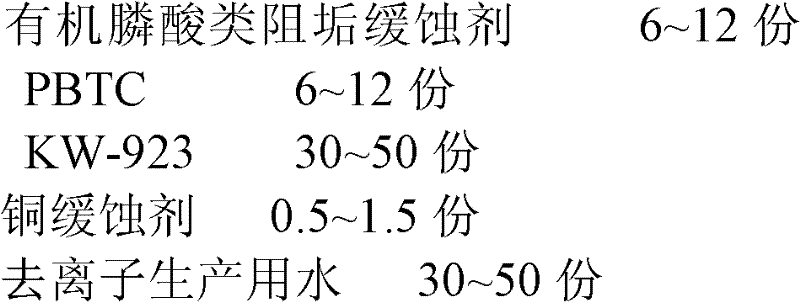

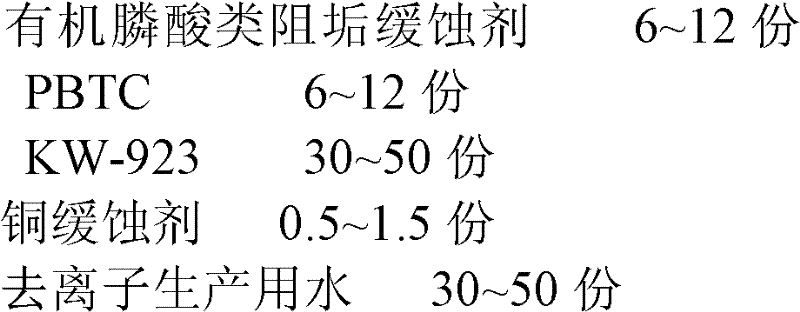

[0025] Corrosion and scale inhibitors for reclaimed water from production waste water used in circulating cooling water, composed of the following raw materials:

[0026] ATMP is 100kg; PBTC is 100kg; KW-923 is 460kg; copper corrosion inhibitor is 10kg; deionized water is 340kg, just mix the above raw materials evenly, and heat it properly when stirring, preferably below 50°C, after stirring evenly The discharge temperature should be below 40°C.

Embodiment 2

[0028] Corrosion and scale inhibitors for reclaimed water from production waste water used in circulating cooling water, composed of the following raw materials:

[0029] 60kg for ATMP; 60kg for HEDP; 300kg for KW-923; 0.5kg for copper corrosion inhibitor; 300kg for deionized water. Stir the above raw materials evenly. When stirring, you can heat it appropriately, preferably below 50°C, stir evenly The final discharge temperature should be below 40°C.

Embodiment 3

[0031] Corrosion and scale inhibitors for reclaimed water from production waste water used in circulating cooling water, composed of the following raw materials:

[0032] 120kg for ATMP; 120kg for hydrolyzed polymaleic anhydride; 490kg for KW-923; 13kg for copper corrosion inhibitor; 460kg for deionized water. Stir the above materials evenly, and heat them appropriately when stirring, preferably below 50°C , After stirring evenly, the discharge temperature should be below 40°C.

[0033] In the above three embodiments, the preparation method of KW-923 referred to comprises the following steps:

[0034] 1) Raw material preparation and dosing

[0035] a. Primer preparation and dosing: First, 300kg of deionized process water and 75kg of isopropanol are sucked into the reaction kettle through a vacuum pump in sequence, so that the liquid level in the reaction kettle is above the minimum liquid level of stirring, and then from the inlet of the reaction kettle Add 115kg maleic anhy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com