Tunnel bituminous pavement clearing functional layer

An asphalt pavement and functional layer technology, applied in the field of paving materials and structures, can solve the problems of deep blackness, difficult to meet the requirements of tunnel use, low bonding strength, etc., to achieve improved adhesion, excellent road surface functionality, tensile strength The effect of improving the pull bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A brightly colored functional layer for tunnel asphalt pavement, which includes brightly colored cementitious materials and brightly colored gravel materials; among them, brightly colored cementitious materials are composed of the following components A and B in a mass ratio of 1:1 It is mixed, and the percentage of each substance is calculated according to the mass percentage of the component:

[0035] A component:

[0036] 25% methyl methacrylate, 30% hydroxyethyl methacrylate

[0037] Butyl methacrylate 5%, calcium carbonate 20%,

[0038] N,N-dimethyl-p-toluidine 5%, titanium dioxide 10%, fumed silica 5%;

[0039] B component:

[0040] 40% methyl methacrylate, 10% hydroxyethyl methacrylate

[0041] Butyl methacrylate 10%, calcium carbonate 30%,

[0042] Dibenzoyl peroxide 3%, titanium dioxide 5%, fumed silica 2%.

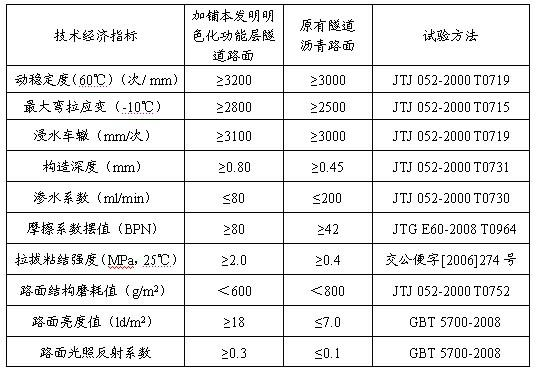

[0043] The bright colored crushed stone material is a commercially available artificial white stone that meets the performance indicators shown in the following table:...

Embodiment 2

[0050] A brightly colored functional layer for tunnel asphalt pavement, which includes brightly colored cementitious materials and brightly colored crushed stone materials; among them, the brightly colored cemented material is composed of the following components A and B in a mass ratio of 1: 1 It is mixed, and the percentage of each substance is calculated according to the mass percentage of the component:

[0051] 40% methyl methacrylate, 20% hydroxyethyl methacrylate

[0052] Butyl methacrylate 9%, calcium carbonate 20%,

[0053] N,N-dimethyl-p-toluidine 2%, titanium dioxide 6%, fumed silica 3%;

[0054] B component:

[0055] Methyl methacrylate 30%, hydroxyethyl methacrylate 20%

[0056] 10% butyl methacrylate, 29% calcium carbonate,

[0057] Dibenzoyl peroxide 2%, titanium dioxide 6%, fumed silica 3%.

[0058] The bright colored crushed stone material is a commercially available artificial white stone that meets the performance indicators shown in the following table:

[0059] Min...

Embodiment 3

[0065] A brightly colored functional layer for tunnel asphalt pavement, which includes brightly colored cementitious materials and brightly colored crushed stone materials; among them, the brightly colored cemented material is composed of the following components A and B in a mass ratio of 1: 1 It is mixed, and the percentage of each substance is calculated according to the mass percentage of the component:

[0066] Methyl methacrylate 30%, hydroxyethyl methacrylate 12%

[0067] 20% butyl methacrylate, 30.5% calcium carbonate,

[0068] N,N-dimethyl-p-toluidine 2%, titanium dioxide 5%, fumed silica 0.5%;

[0069] B component:

[0070] Methyl methacrylate 10%, hydroxyethyl methacrylate 32%

[0071] 20% butyl methacrylate, 28% calcium carbonate,

[0072] Dibenzoyl peroxide 5%, titanium dioxide 4%, fumed silica 1%.

[0073] The bright colored crushed stone material is a commercially available artificial white stone that meets the performance indicators shown in the following table:

[0074] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com