Preparation method for low temperature curing polyester resin with high leveling performance

A polyester resin and thermosetting technology, applied in the field of preparation of mixed polyester resin, can solve the problems of poor leveling performance, lower curing temperature and high viscosity of the board surface, and achieve the effect of good leveling and improving toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

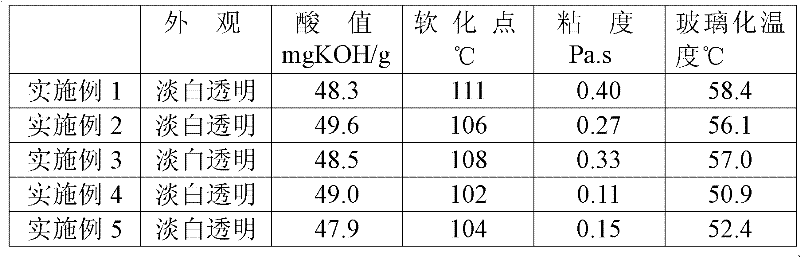

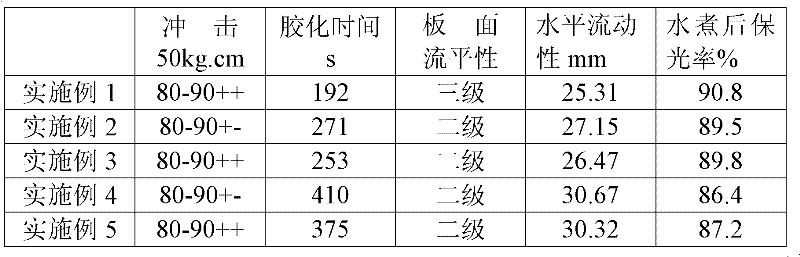

Examples

Embodiment 1

[0020] A. Synthesis process: In the synthesis kettle, the temperature of the kettle is raised to 90-100°C, and 5.57kg of neopentyl glycol, 1.2kg of ethylene glycol, 0.5kg of diethylene glycol, 12kg of purified terephthalic acid, Diacid 0.5kg and monobutyl tin oxide 22g. After feeding the materials, seal the kettle and heat it up, and at the same time, fill it with nitrogen for production protection. When the temperature rises to 245°C, keep the reaction for 2 hours. When the top temperature of the reaction kettle drops below 70°C, take samples for testing. The acid value is 18-22mgKOH / g ;

[0021] B. Vacuum pumping process: lower the temperature of the kettle to 230°C, carry out vacuum operation, the vacuum degree of the reactor is less than -0.090MPa, maintain this condition for 2 hours, and take a sample to detect the acid value at 6-9mgKOH / g;

[0022] C. Curing process: lower the temperature of the kettle to below 210°C, add 1.25kg of trimellitic anhydride, and maintain th...

Embodiment 2

[0025] A. Synthesis process: In the synthesis kettle, the temperature of the kettle is raised to 90-100°C, and 5.57kg of neopentyl glycol, 1.2kg of ethylene glycol, 0.5kg of diethylene glycol, 12kg of purified terephthalic acid, and Monobutyltin oxide 22g. After feeding the materials, seal the kettle and heat it up, and at the same time, fill it with nitrogen for production protection. When the temperature rises to 245°C, keep the reaction for 2 hours. When the top temperature of the reaction kettle drops below 70°C, take samples for testing. The acid value is 18-22mgKOH / g ;

[0026] B. Cooling process: lower the temperature of the kettle to below 210°C, put in 0.5kg of adipic acid and 0.95kg of trimellitic anhydride, then slowly raise the temperature to 220°C, the top temperature rises, and maintain the reaction at 220°C for 1.5 hours, until the top temperature drops to 70°C The following samples were taken for testing, and the acid value was 58-62mgKOH / g;

[0027] C. Vacuu...

Embodiment 3

[0030] Except that in C, vacuuming and curing process, the vacuum reaction time is 2.5 hours, and the viscosity is except that the viscosity is 0.3-0.4Pa.s, all the other are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com