Method for preparing micro nano starch granules emulsifier and application thereof

A technology of starch granules and emulsifiers, applied in the field of micro-nano starch granule emulsifiers in food and cosmetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Weigh 10.0g of waxy corn amylopectin and add it to 100mL, 3.16mol / L H 2 SO 4 Put the solution in a round-bottomed flask, put the flask into an oil bath at 40°C, and stir evenly at a speed of 100 rpm. After reacting for 6 days, the precipitated product was collected by centrifugation, washed repeatedly by centrifugation and water until it became neutral, and then freeze-dried to obtain micro-nano starch granules.

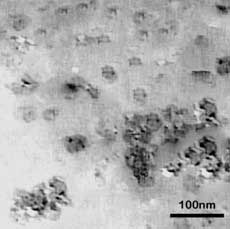

[0017] Determination of morphology and particle size of micro-nano starch granules: Disperse micro-nano starch granules in toluene, use a pipette to pick up the droplet and drop it on the copper grid. After the toluene volatilizes, the sample is stained with osmium tetroxide. The operating voltage was 80kV, and the microscopic morphology of the samples was observed with a Hitachi H600 transmission electron microscope.

[0018] figure 1 It is a transmission electron micrograph of micro-nano starch granules obtained after acid degradation. It can ...

Embodiment 2

[0021] Example 2 Weigh 10.0 g of potato starch and add it into a round bottom flask containing 100 mL of 5 mol / L HCl solution, put the flask into an oil bath at 40°C, and stir evenly at a speed of 100 rpm. After reacting for 1 day, the precipitated product was collected by centrifugation, washed repeatedly by centrifugation and water until it became neutral, and then freeze-dried to obtain micro-nano starch granules.

Embodiment 3

[0022] Example 3 Weigh 10.0g of tapioca starch and add it to 100mL, 1mol / L HNO 3 Put the solution in a round-bottomed flask, put the flask into an oil bath at 40°C, and stir evenly at a speed of 100 rpm. After reacting for 10 days, the precipitated product was collected by centrifugation, washed repeatedly by centrifugation and water until it became neutral, and then freeze-dried to obtain micro-nano starch granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com