Method for fluoride-free synthesis of AlPO4-34 from mixed solvents through hot process

A synthesis method and technology of hydrofluoric acid, applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali exchange phosphate, etc., to achieve the effect of broad application prospect, simple implementation conditions and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

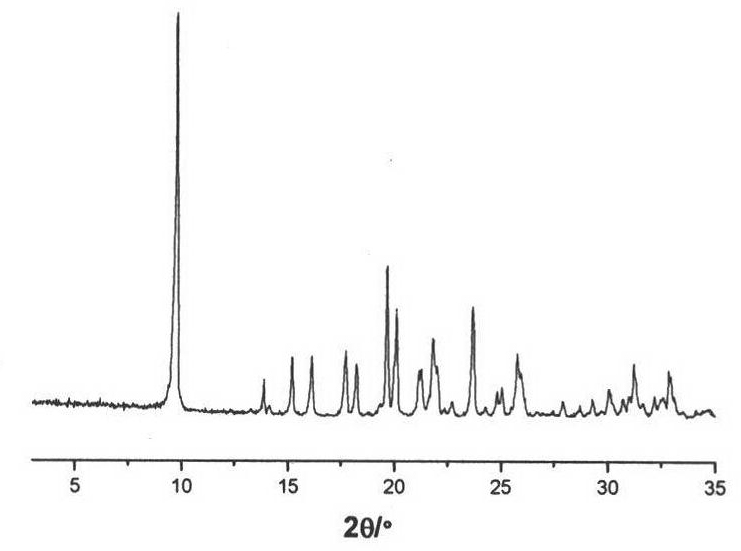

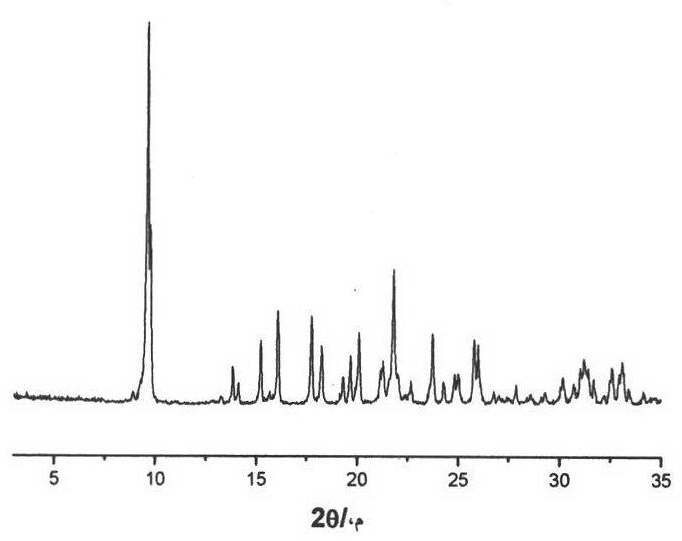

Image

Examples

Embodiment 1

[0018] At room temperature, 6.60 milliliters of water was mixed with 1.74 grams of pseudo-boehmite (weight loss of 24.75% at 600° C.), and then 3.40 milliliters of isopropanol (analytical pure) was added, and stirred and mixed evenly. 1.20 ml of phosphoric acid (85%) was added dropwise, and the reaction was stirred evenly. Then, 1.97 ml of morpholine (analytical pure) was pipetted with a pipette, slowly added to the jelly, and stirred for half an hour. Transfer to a 25 ml stainless steel reactor, and crystallize at 170° C. for 6 days under autogenous pressure. Quenching, washing, filtering, and natural drying to obtain the molecular sieve powder.

Embodiment 2

[0020] At room temperature, take 2.50 milliliters of water and 1.74 grams of pseudo-boehmite (24.75% weight loss at 600° C.) and mix them, then add 7.50 milliliters of ethylene glycol (analytical grade), and stir and mix evenly. Add 1.20 milliliters of phosphoric acid ((85%) dropwise, stir and react evenly, then pipette 3.94 milliliters of morpholine (analytical pure), slowly add in the above-mentioned jelly, stir for half an hour. Transfer to 25 milliliters of stainless steel In the reaction kettle, crystallize at 185°C for 4 days under autogenous pressure. Quench, wash, filter, and dry naturally to obtain AlPO 4 -34 molecular sieve raw powder.

Embodiment 3

[0022] At room temperature, get 2.50 milliliters of water and mix with 0.87 gram of pseudo-boehmite (weight loss 24.75% at 600 DEG C), then add 7.50 milliliters of ethylene glycol (analytical pure), stir and mix well, add 0.91 milliliters of phosphoric acid (85 %), stir and react evenly, then pipette 3.94 milliliters of morpholine (analytical pure) and slowly add in the above-mentioned jelly, and stir for half an hour. Transfer to a 25 ml stainless steel reaction kettle, and crystallize at 200° C. for 1 day under autogenous pressure. Quenching, washing, filtering, and natural drying to obtain AlPO 4 -34 molecular sieve raw powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com