Direct current electric field enhanced powder chromizing method for inner surface of tubular part, and apparatus thereof

A technology of DC electric field and inner surface, applied in the field of chemical heat treatment on the surface of metal parts, can solve the problems of high price, high cost, long processing time, etc., to improve the performance and life, increase the concentration and activity, and shorten the holding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

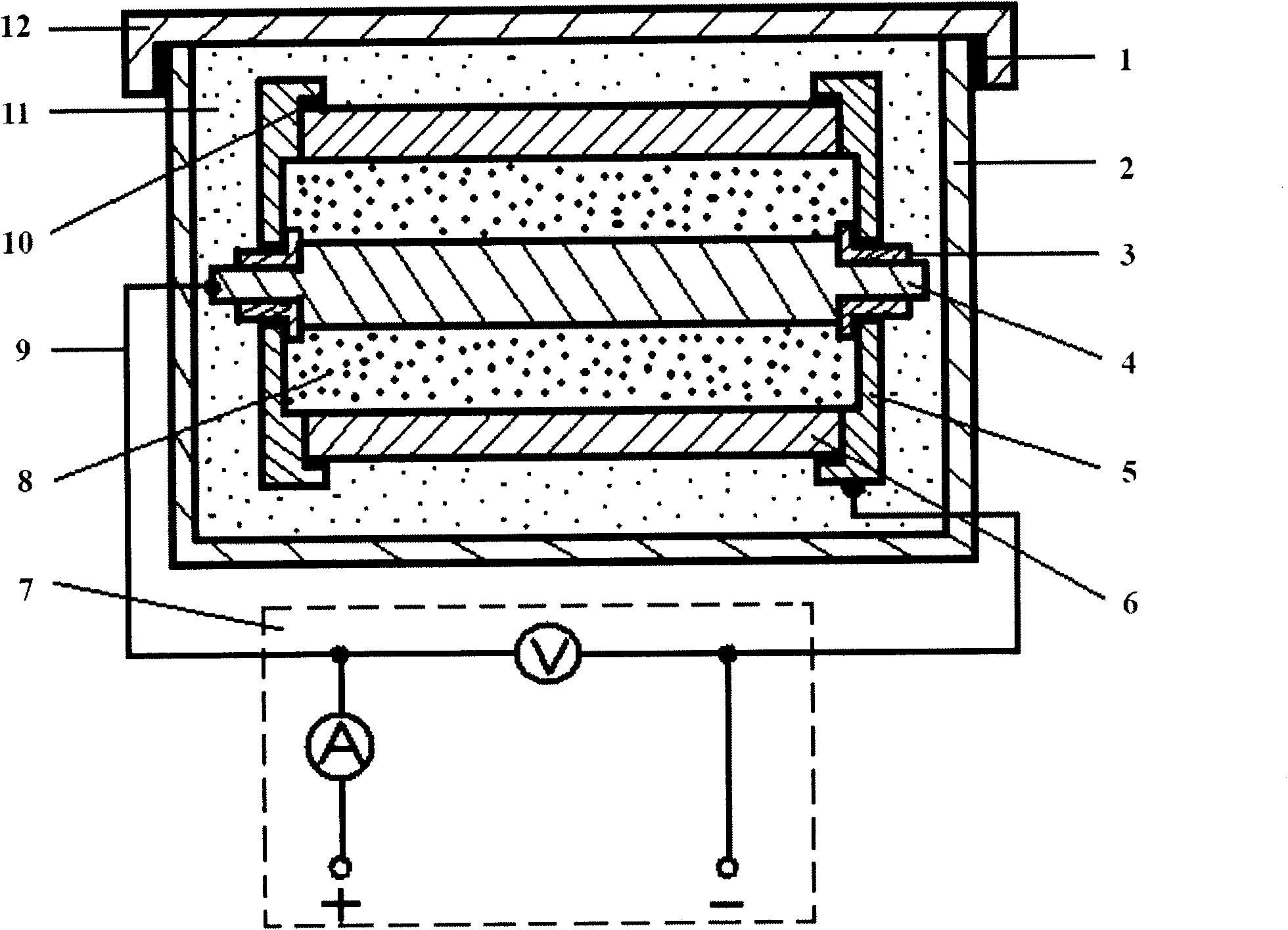

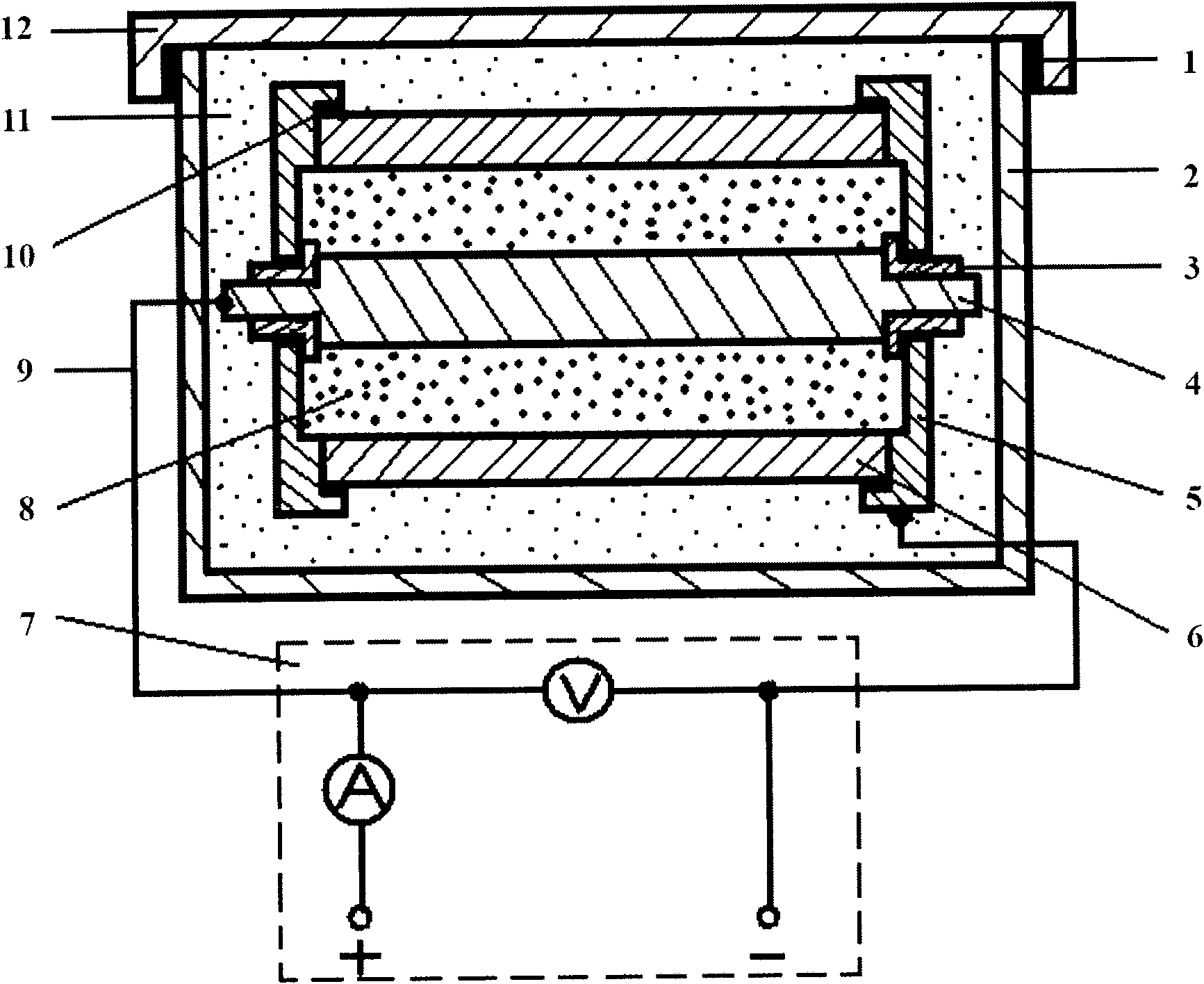

[0021] Material to be infiltrated: seamless steel pipe made of 08Cr2AlMo steel, with an outer diameter of 25mm, an inner diameter of 20mm, and a length of 30mm; 2%; potassium fluoroborate, 5%), loosening agent (charcoal, 1%), filler (silicon carbide, balance).

[0022] Fill the solid powder chromizing agent 8 composed of the above materials into the steel pipe sample 6 to be chromized on the inner wall, place the cylindrical electrode 4 in the infiltrating agent, the distance between the cylindrical electrode 4 and the inner wall of the steel pipe 6 to be infiltrated is 8mm, and the two ends of the steel pipe 6 Install sealing cover 5 and insulating cover 3 at both ends of cylindrical electrode 4, and seal with refractory mud sealing material 10 again. The cylindrical electrode 4 is used as the positive pole, and the steel pipe 6 is used as the negative pole. The two poles are respectively connected to the positive and negative poles of a DC power supply system 7 with a contin...

Embodiment 2

[0025] Material to be infiltrated: seamless steel pipe made of 08Cr2AlMo steel, the outer diameter of the steel pipe is 25mm, the inner diameter is 20mm, and the length is 30mm. 5%; ammonium chloride, 1%), loosening agent (charcoal, 1%), filler (silicon carbide, balance).

[0026] The chromizing method and device are the same as in Example 1, the chromizing temperature: 750° C., the chromizing holding time is 4 hours, the distance between the cylindrical positive electrode and the infiltrated steel pipe sample (negative electrode) is 8 mm, and the A DC electric field with a current strength of 6 amps. Test results: The inner wall of the 08Cr2AlMo steel pipe obtained a chromizing layer of nearly 55 μm; while using the same infiltrating agent formula, using the existing conventional powder chromizing process, the same chromizing process at 750 ° C for 4 hours, the thickness of the chromizing layer on the inner wall of the 08Cr2AlMo steel pipe less than 10 μm.

Embodiment 3

[0028] Material to be infiltrated: welded steel pipe of 20 steel material, the outer diameter of the steel pipe is 30mm, the inner diameter is 24mm, and the length is 30mm; the composition of the chromizing agent: chromium donor (ferrochromium, content 40%), activator and infiltration agent (potassium fluoroborate, 5%; ammonium chloride; 1%), loosening agent (charcoal, 5%), filler (silicon carbide, balance).

[0029] The chromizing method and device are the same as in Example 1, the chromizing temperature: 800° C., the chromizing time of 4 hours, the distance between the cylindrical positive electrode and the infiltrated steel pipe sample (negative electrode) is 8 mm, and the distance between the cylindrical positive electrode and the infiltrated steel pipe sample is A DC electric field with a current strength of 6 amperes was applied. Test results: A chromizing layer of about 70 μm was obtained on the inner wall of the 20 steel pipe, and the same formula of the infiltrating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com