Low-temperature high-speed solid-powder chromium-impregnation method under action of direct current field

A solid powder, DC electric field technology, applied in solid diffusion coating, metal material coating process, coating and other directions, can solve the problems of low utilization rate of penetration agent, complicated process operation, reduced holding time, etc., and achieve simple operation. The effect of easy operation, speeding up infiltration rate and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Infiltrated material: 45 steel; composition of chromizing agent: chromium donor (ferrochrome, content 60%), activator (ammonium chloride, content 1%), filler (quartz sand, content 39%).

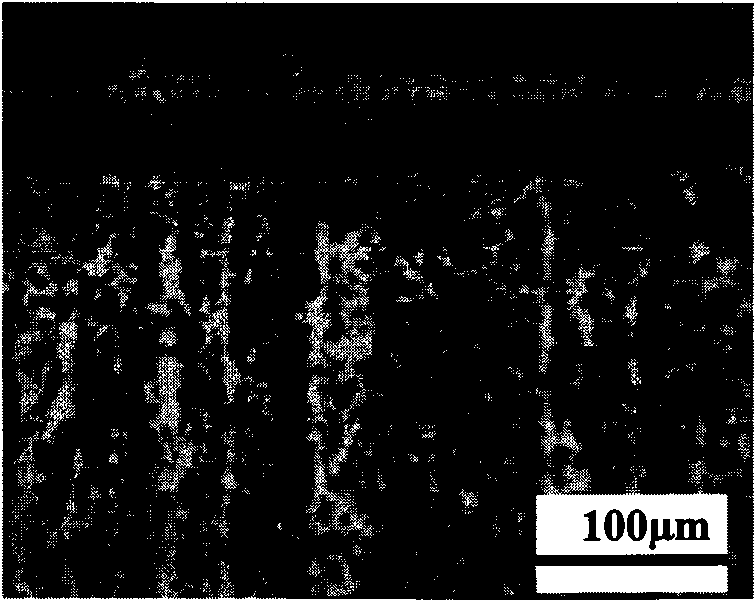

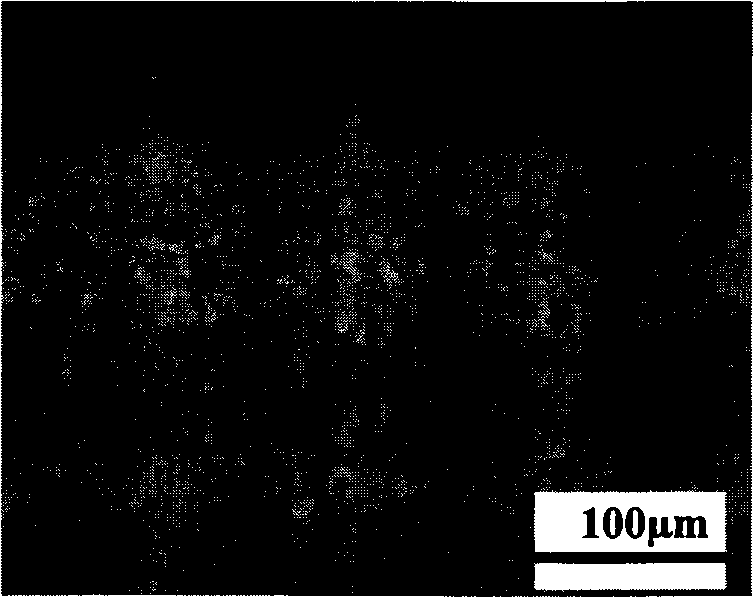

[0021] Place a rectangular plate-shaped electrode in the solid powder chromizing agent composed of the above substances, use this electrode as the positive electrode, and use the part as the negative electrode. The two electrodes are respectively connected to the positive and negative poles of a DC power supply whose voltage is continuously adjustable within the range of 5-100V. The plate electrode and the parts to be chromized are sealed in the infiltration box together with the powder chromizing agent. Then place the infiltrating box in a box-type resistance furnace to heat, the chromizing temperature is 700°C, and the chromizing time is 4 hours. When the furnace temperature reaches the set value, a voltage of 10V is applied between the two electrodes. Test results: 45 steel obtains ...

Embodiment 2

[0023] Infiltrated material: 20 steel; composition of chromizing agent: chromium donor (ferrochrome, content 60%), activator (ammonium chloride, content 1%), filler (chromium oxide, content 39%).

[0024] Place a trapezoidal plate-shaped electrode in the solid powder chromizing agent composed of the above substances, use this electrode as the positive electrode, and use the part as the negative electrode. The two electrodes are parallel to each other. The distance between the plate-shaped positive electrode and the part to be chromized is 60mm. The two electrodes are respectively connected to the positive and negative poles of a DC power supply whose voltage is continuously adjustable within the range of 5-100V. The plate electrodes and parts are sealed in the seepage box together with the powder infiltration agent, and then the infiltration box is placed in the box. Heating in a type resistance furnace, the chromizing temperature is 750°C, and the chromizing time is 4 hours. W...

Embodiment 3

[0026] Infiltrated material: 20 steel, 45 steel, composition of chromizing agent: chromium donor (ferrochrome, content 60%), activator (ammonium chloride, content 1%), filler (quartz sand, content 39%).

[0027] Place a circular plate-shaped electrode in the solid powder chromizing agent composed of the above substances, use the electrode as the positive electrode, and use the part as the negative electrode. The two poles are parallel to each other. The distance between the plate-shaped positive electrode and the infiltrated sample is 90mm. Connected to the positive and negative poles of a dedicated DC power supply whose voltage is continuously adjustable within the range of 5-100V, the plate electrodes and parts are sealed in the seepage box together with the powder infiltration agent, and then the infiltration box is placed in a box-type resistance furnace Medium heating, the chromizing temperature is 850°C, and the chromizing time is 4 hours. When the furnace temperature rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com