Light emitting diode (LED) chip driving system with thermal management function and control method thereof

A LED chip and drive system technology, applied in the field of lighting, can solve the problems of low heat dissipation efficiency, slow heat dissipation speed, unsuitable for high temperature working environment, etc., and achieve the effect of saving power and timely heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

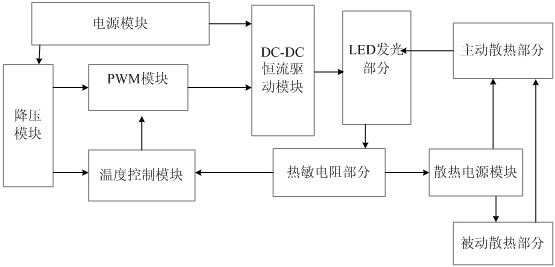

[0028] The present invention provides an LED chip driving system with thermal management function, including LED chip modules and a control system, which will be introduced separately below.

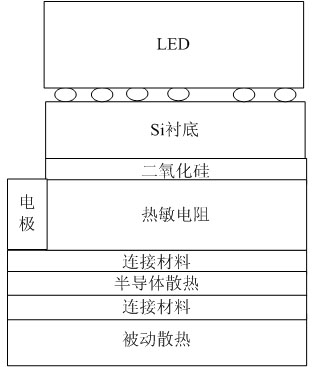

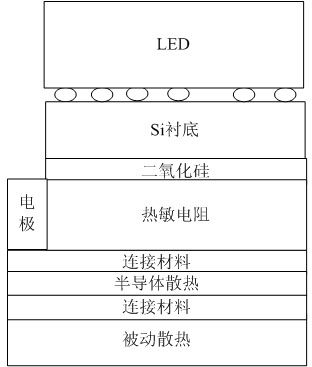

[0029] First, if figure 1 and figure 2 As shown, the LED chip module includes an LED light-emitting part, a thermistor part, an active heat dissipation part, a metal heat conduction part and a passive heat dissipation part, which will be introduced respectively below.

[0030] The LED light-emitting part is a flip-chip LED structure, and the thermistor part is made of a silicon-based thermistor, and the LED light-emitting part and the thermistor part are connected by welding; by connecting the traditional LED and thermistor The resistors are integrated together, and the core temperature of the LED can be directly measured through the thermistor. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com