Composite material having solar cell and production method thereof

A technology of solar cells and composite materials, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of inability to obtain two-phase benefits, solar cell obstruction, damage or destruction, and achieve good wear resistance and light weight Translucency and low molding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

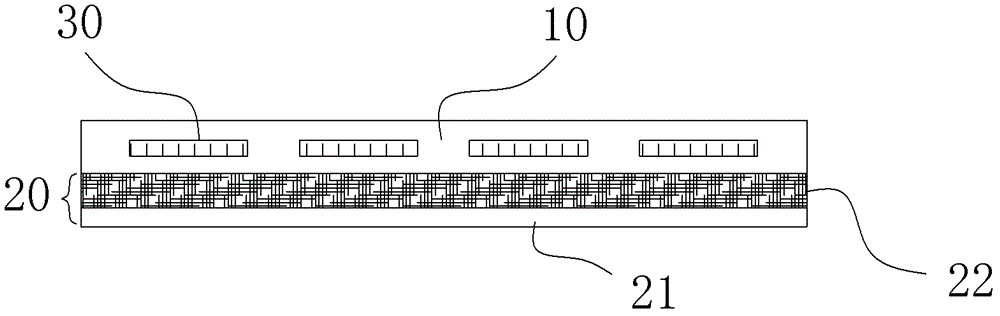

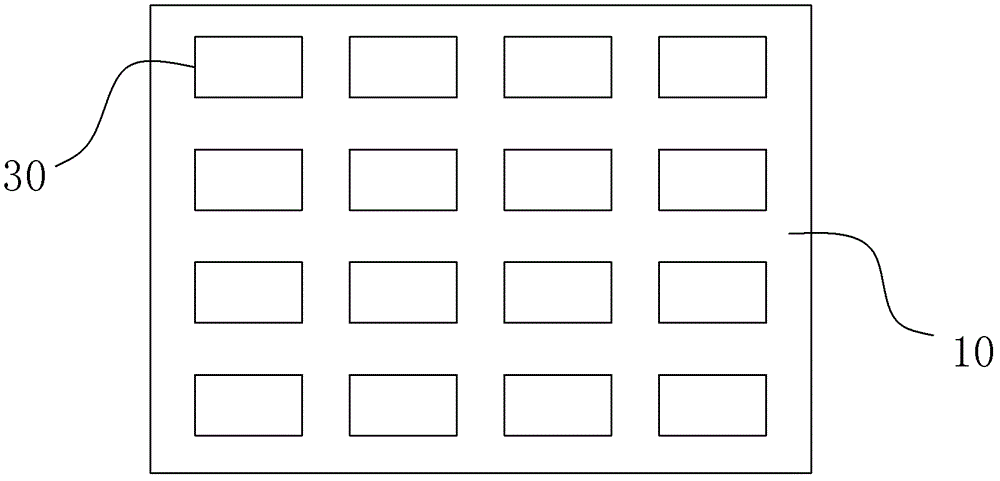

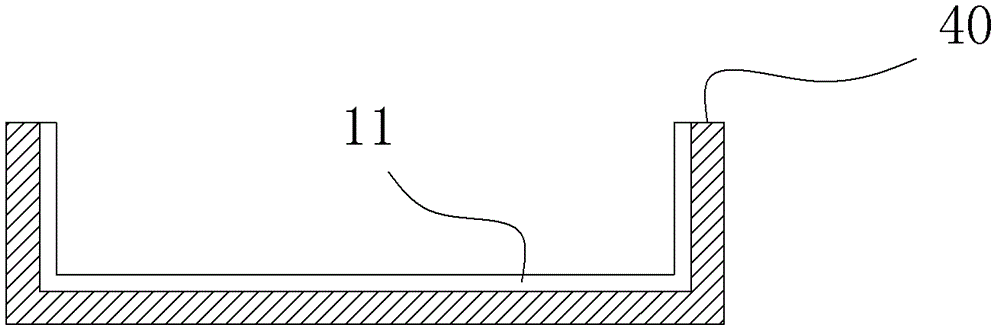

[0023] A composite material with a solar cell, which is composed of a plurality of mutually stacked and connected layers, and the layers are as follows from top to bottom: a highly transparent resin adhesive layer 10, a layer used to increase the strength of the highly transparent resin adhesive layer 10 Reinforcing layer 20, the solar cells 30 are embedded in the highly transparent resin adhesive layer 10 or embedded in the bottom surface thereof, such as Figure 1-2 shown.

[0024] As a further preferred version of the present invention: as figure 1 As shown, the reinforcement layer 20 includes a common resin glue layer 21, and a carbon fiber layer 22 is interposed between the common resin glue layer 21 and the highly transparent resin glue layer 10 and is laminated and connected between the two. In this way, relying on the characteristics of high strength and light weight of carbon fiber to make up for the defects of easy deformation and low strength of high transparent re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com