Extracting and zero-discharging method of seawater bittern multi-elements

A zero-emission, multi-element technology, applied in chemical instruments and methods, heavy water, magnesium halide, etc., can solve the problems of zero discharge of seawater bittern, waste of resources, poor economic benefits, etc., to reduce the pressure of sea salt production, Effect of avoiding marine pollution and protecting ecological balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For further illustrating the present invention, specifically illustrate in conjunction with following examples:

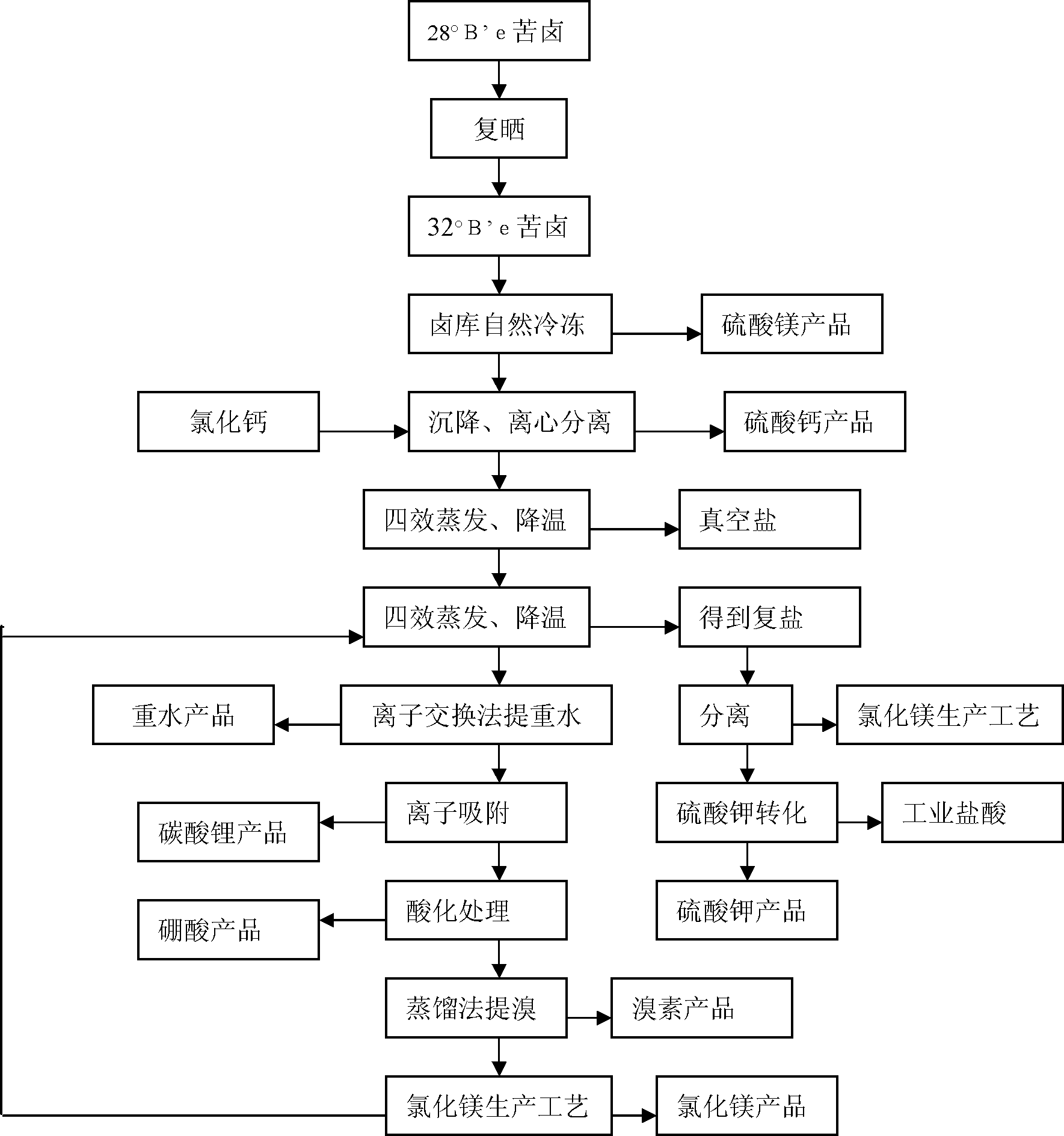

[0031] combine figure 1 , the seawater bittern multi-element extraction and zero discharge method of the present invention comprises the following steps:

[0032] (1) The bittern of 28 degrees Baume is re-dried to obtain the bittern of more than 32 degrees Baume;

[0033] (2) the bittern obtained in the previous step is naturally frozen in the bittern storehouse, and the temperature is -5° C. to obtain the magnesium sulfate product;

[0034] (3) Calcium chloride is added in the bittern after the previous step processing, and calcium sulfate product is obtained after sedimentation and centrifugation;

[0035] (4) The bittern from which calcium sulfate is separated is subjected to four-effect evaporation, and the temperature of the termination boiling point is controlled to reach 112-115° C., and solid-liquid separation is carried out to obtain refined salt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com