Technology for synthesizing ionic liquid

A technology of ionic liquid and synthesis process, which is applied in the field of chemical engineering, can solve problems such as many unforeseen factors, little economic significance, and difficulties in microwave equipment, and achieve good product quality consistency, accurate control of process conditions, and stable and consistent product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

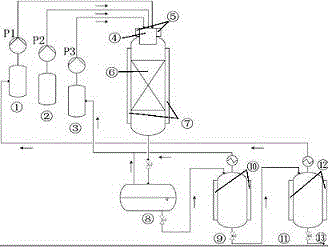

[0030] figure 1 It is the synthesis process equipment flowchart of ionic liquid of the present invention, ①② is respectively the raw material tank of two kinds of reaction materials, ③ is solvent tank. P1, P2, and P3 are three plunger pumps, which transport the reaction materials and solvents in ①②③ to ④. ④ is a jet mixing unit, where the raw materials and solvents in ①②③ are fully mixed. The condenser ⑤ is used to control the mixing temperature at the jet mixer ④. ⑥ is the reaction unit, the reactants mixed at ④ enter ⑥ for reaction, and the heater ⑦ controls the reaction temperature of the reaction unit ⑥. ⑧ is the first separation device, and the upper part of the separated substance is the substance in the solvent tank ③, so it is transported back to the solvent tank ③. Substances in the lower part are fed into ⑨. ⑨ is the second-step separation device. The upper part of the separated substance is the substance in the solvent tank ③, so it is transported back to the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com