Method for preparing early strength type polycarboxylic acid water-reducing agent

A polycarboxylic acid-based and water-reducing agent technology is applied in the field of concrete admixtures in building materials, which can solve the problems of large amount of water-reducing agent, poor product stability of water-reducing agent, influence of product adaptability, etc., and achieves convenient preparation process. , The effect of good product stability and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

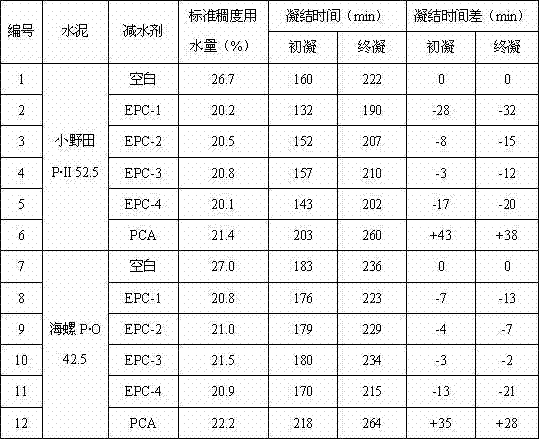

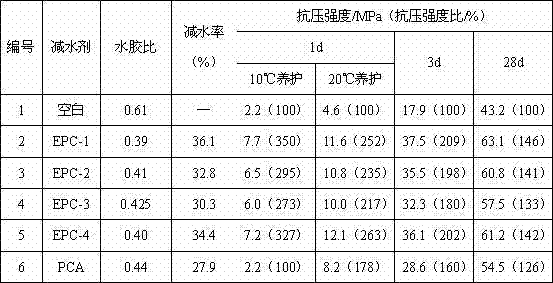

Examples

Embodiment 1

[0029] 1. The composition and ratio of the monomers used are as follows:

[0030] 1) Modified polyoxyalkylene ethers with unsaturated double bonds, accounting for 85% of the total weight of the monomers, and its general structural formula is

[0031]

[0032] In the general formula, AO is an oxyalkylene group with 2 carbon atoms, n=50;

[0033] 2) Acrylic acid, accounting for 7% of the total weight of monomers;

[0034] 3) Sodium propenyl sulfonate, accounting for 5% of the total weight of the monomer;

[0035] 4) Acrylamide, accounting for 3% of the total weight of monomers.

[0036] 2. The preparation process is as follows:

[0037] 1) Add the modified polyoxyalkylene ether and sodium propylene sulfonate into the reaction kettle according to the above ratio, add deionized water, make the concentration of the monomer mixed aqueous solution in the kettle be 50%, and slowly raise the temperature to 65°C;

[0038] 2) Add the mixed solution of acrylic acid, acrylamide and ...

Embodiment 2

[0042] 1. The composition and ratio of the monomers used are as follows:

[0043] 1) Modified polyoxyalkylene ethers with unsaturated double bonds, accounting for 90% of the total weight of the monomers, and its general structural formula is

[0044]

[0045] In the general formula, AO is an oxyalkylene group with 2 carbon atoms, n=70;

[0046] 2) Acrylic acid, accounting for 6% of the total weight of monomers;

[0047] 3) Sodium propenyl sulfonate, accounting for 2% of the total weight of the monomer;

[0048] 4) Acrylamide, accounting for 2% of the total weight of monomers.

[0049] 2. The preparation process is as follows:

[0050] The preparation process is completely the same as in Example 1. The inventive product EPC-2 was obtained.

Embodiment 3

[0052] 1. The composition and ratio of the monomers used are as follows:

[0053] 1) Modified polyoxyalkylene ethers with unsaturated double bonds, accounting for 80% of the total weight of monomers, and its general structural formula is

[0054]

[0055] In the general formula, AO is a mixture of oxyalkylene groups with 2 to 4 carbon atoms, n=20;

[0056] 2) Acrylic acid, accounting for 15% of the total weight of monomers;

[0057] 3) Sodium vinyl sulfonate, accounting for 5% of the total monomer weight;

[0058] 4) Acrylamide, accounting for 5% of the total weight of monomers.

[0059] 2. The preparation process is as follows:

[0060] 1) Add the modified polyoxyalkylene ether and sodium vinyl sulfonate into the reaction kettle according to the above ratio, add deionized water, make the concentration of the monomer mixed aqueous solution in the kettle be 50%, and slowly raise the temperature to 50°C;

[0061] 2) Add the mixed solution of acrylic acid, acrylamide and mer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com