Nickel and cobalt-based high-temperature alloy containing rare earth elements and preparation method thereof

A rare earth element and superalloy technology, applied to parts used under high temperature and high stress, nickel-cobalt-based deformed superalloy containing rare earth elements and its preparation field, can solve the problem of easy expansion of fatigue cracks, deterioration of hot working performance, low cycle Fatigue performance reduction and other problems, to achieve the effects of excellent room temperature to high temperature tensile strength, excellent processability, excellent medium temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

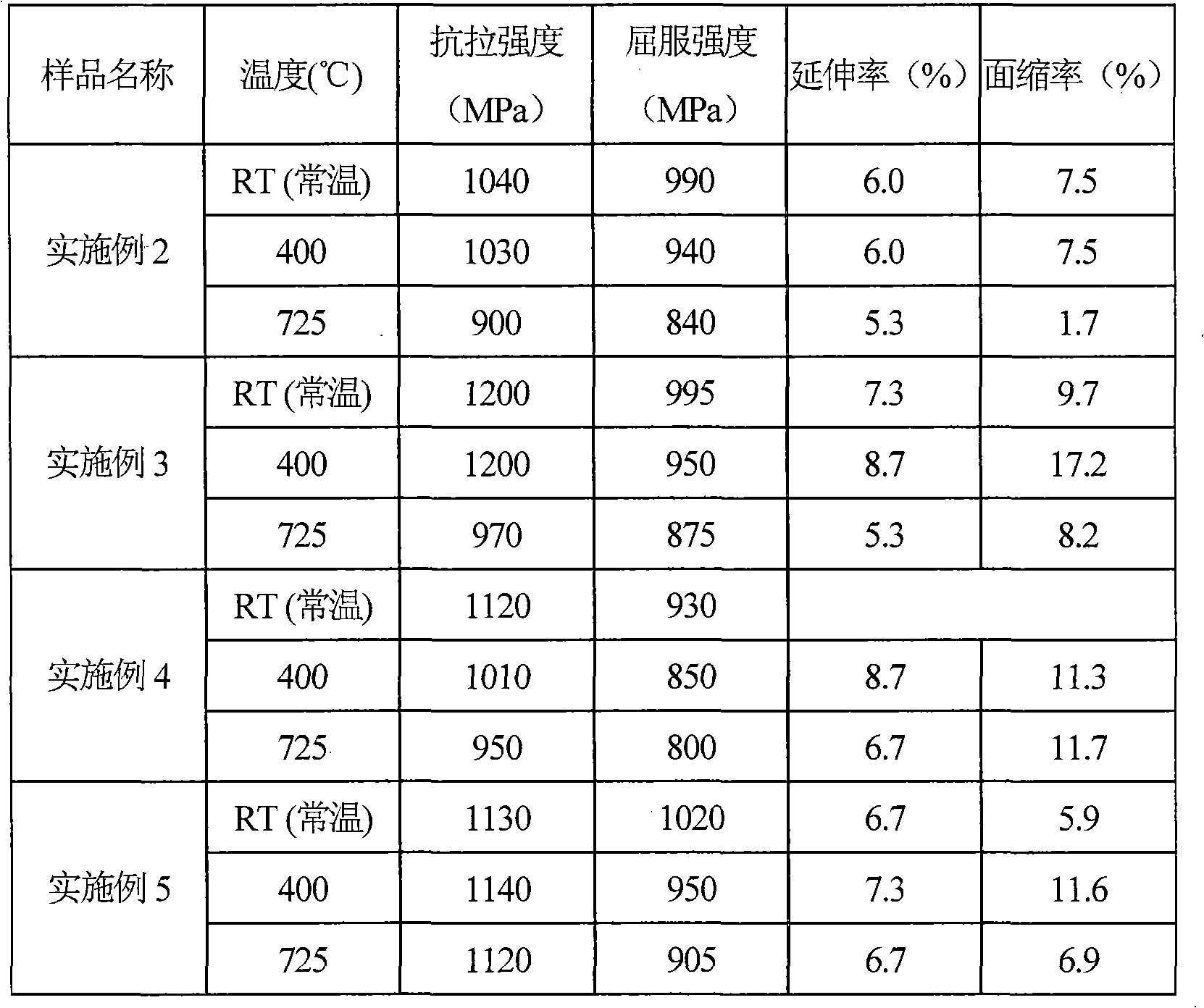

[0026] The present invention will be further described below by way of examples.

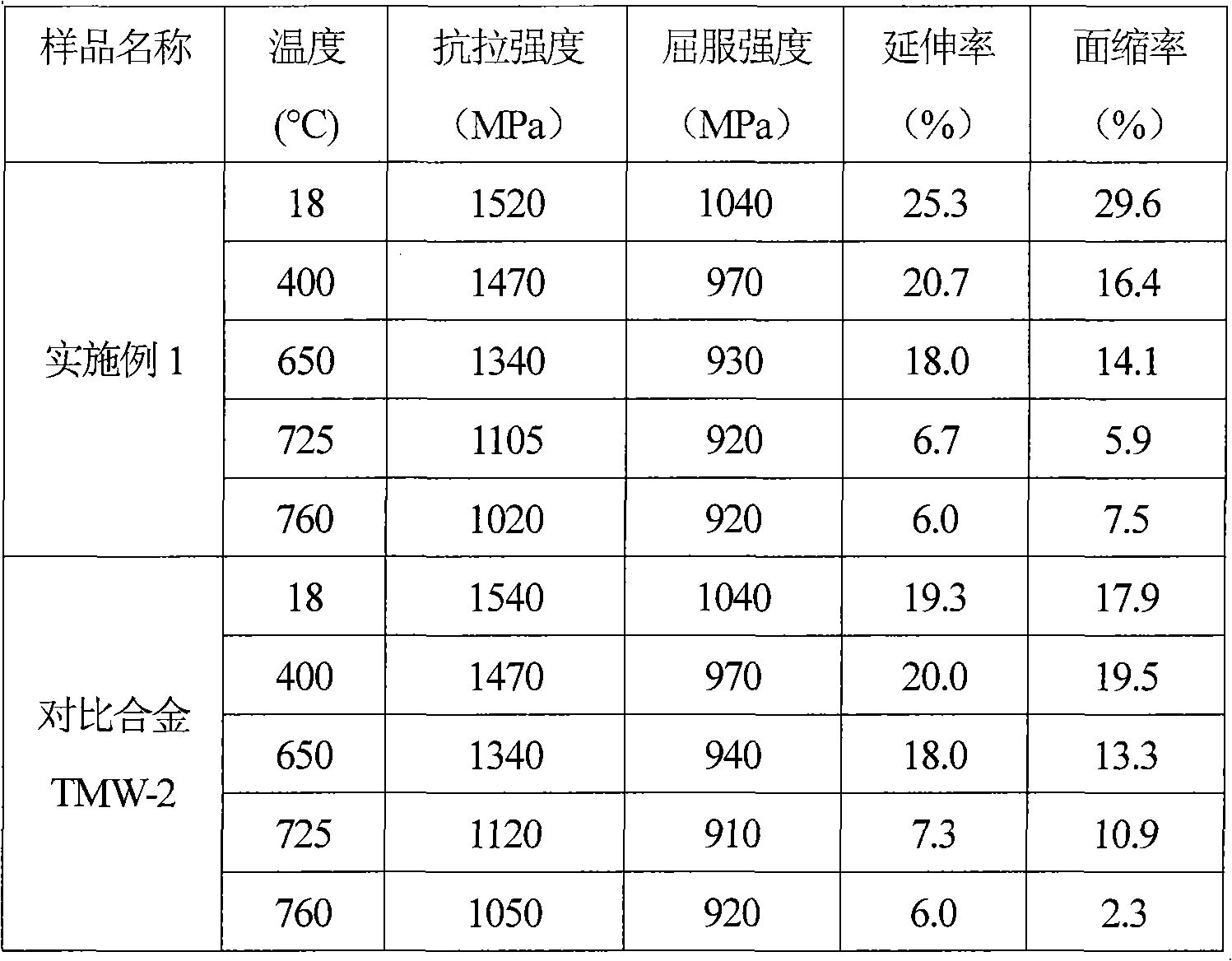

[0027] According to the range of chemical composition, samples of the alloy of the present invention were prepared. The specific chemical composition is shown in Table 1. For the convenience of comparison, the chemical composition of the comparative alloy TMW-2 is also listed in Table 1. The alloy of this example is smelted in a vacuum induction furnace, and cast into a master alloy whose chemical composition meets the requirements and has no obvious casting defects. The ingot is homogenized at 1150°C and 1180°C for 8 hours, wrapped, and then cast at 1150°C. Hot extrusion or hot forging experiments.

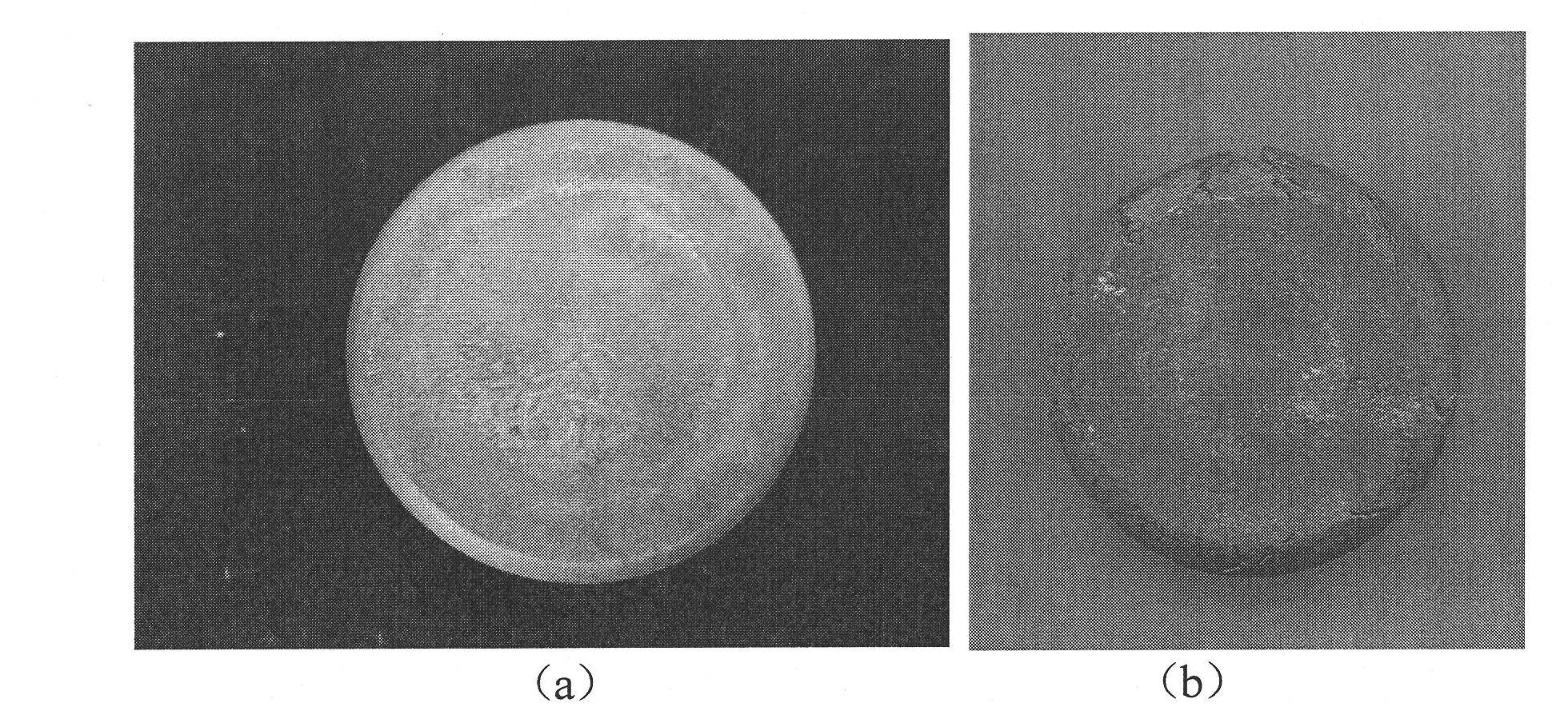

[0028] The samples of the alloy of the present invention and the comparison alloy after hot forging at 1120°C are as follows: figure 1 shown. Depend on figure 1 It can be seen that the alloy of the present invention is smooth and has no cracks, while the surface of the comparative alloy has a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com