Preparation method of crack-free optical crystal

A photonic crystal, crack-free technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of cumbersome process, high preparation cost, unsafe hazards, etc., and achieve good universality, simple operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

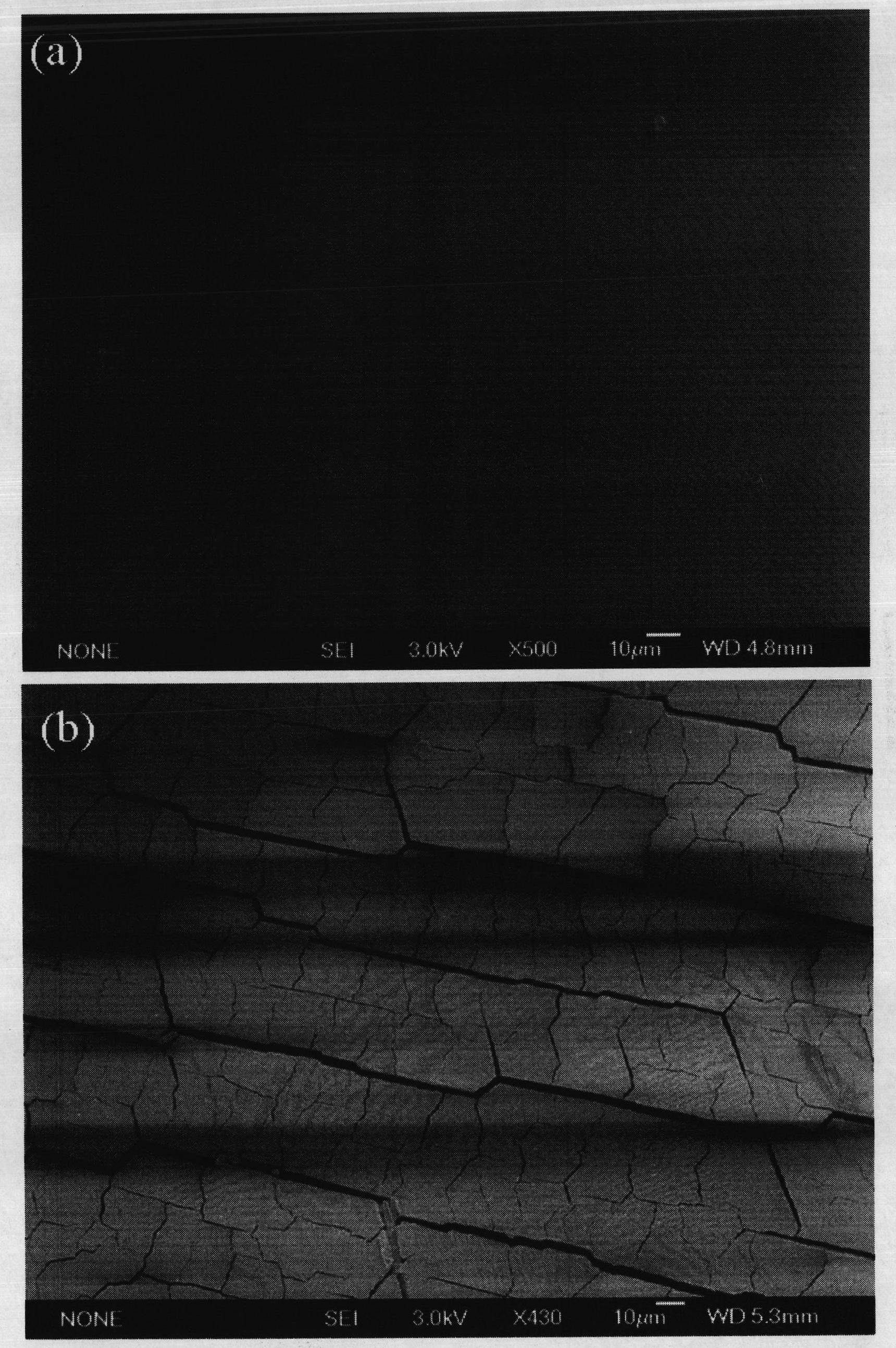

Embodiment 1

[0024] Monodisperse poly(styrene-methyl methacrylate-acrylic acid) polymer colloidal microspheres with a particle size of 80 nm were ultrasonically dispersed in water to form an emulsion with a mass fraction of 0.01%, and then an aluminum foil with a thickness of 0.001 cm was vertically Put it into the emulsion, under the condition that the temperature is 50°C and the relative humidity is 50%, the above-mentioned monodisperse colloidal microspheres are assembled on the surface of the above-mentioned aluminum foil by utilizing the capillary pressure of the meniscus of water formed on the surface of the aluminum foil, and the self-assembly A large-area opal structure photonic crystal without cracks is formed, and its photonic band gap is located at 200nm.

Embodiment 2

[0026]Monodisperse polystyrene colloidal microspheres with a particle size of 1100nm were ultrasonically dispersed in water to form an emulsion with a mass fraction of 20%, and then an aluminum foil with a thickness of 0.07cm was vertically placed in the emulsion at a temperature of 85°C. Under the condition of a relative humidity of 85%, the above-mentioned monodisperse colloidal microspheres are assembled on the surface of the above-mentioned aluminum foil by using the capillary pressure of the meniscus of water formed on the surface of the aluminum foil, and self-assemble into a large-area opal structure photonic crystal without cracks. The bandgap is located at 2500nm.

Embodiment 3

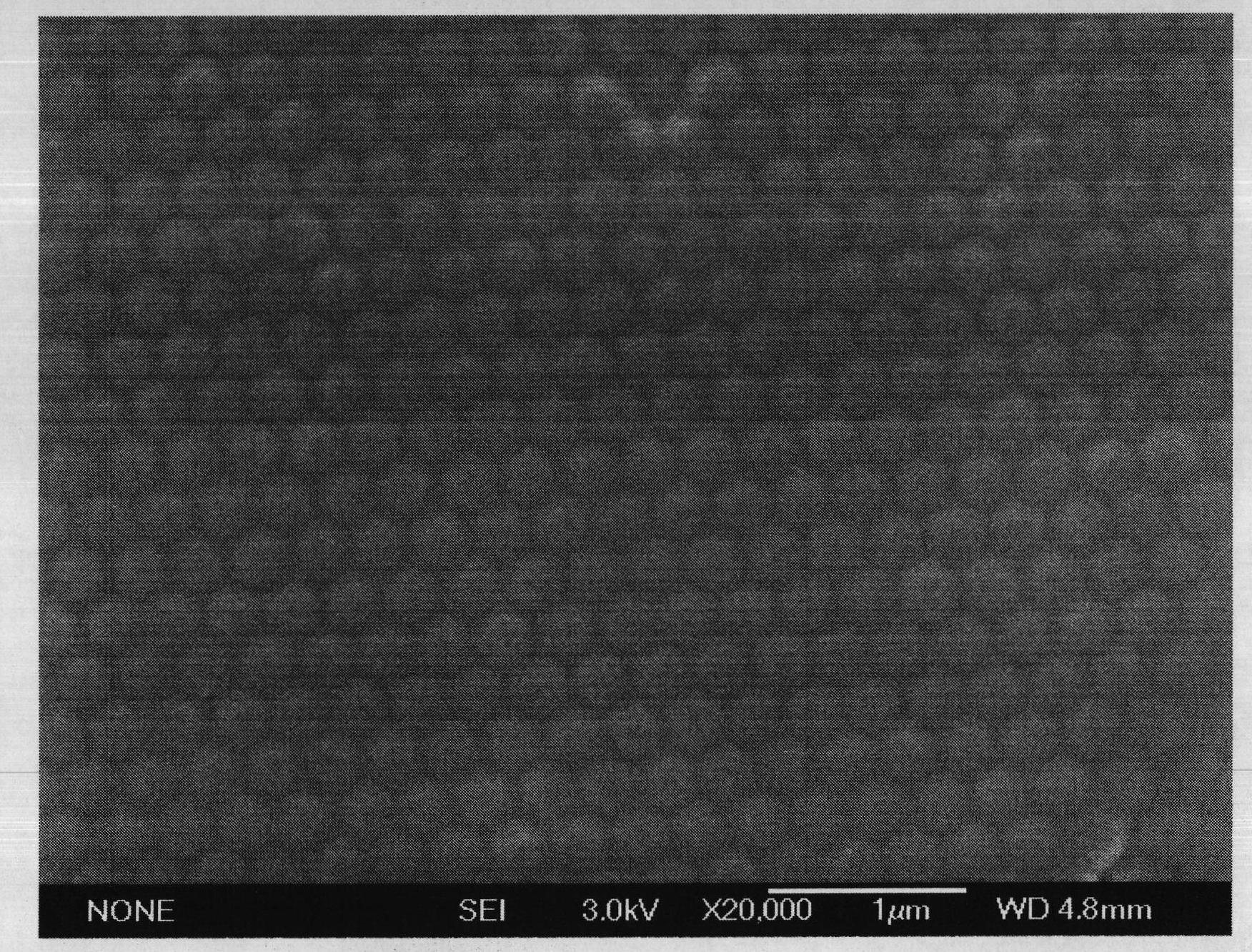

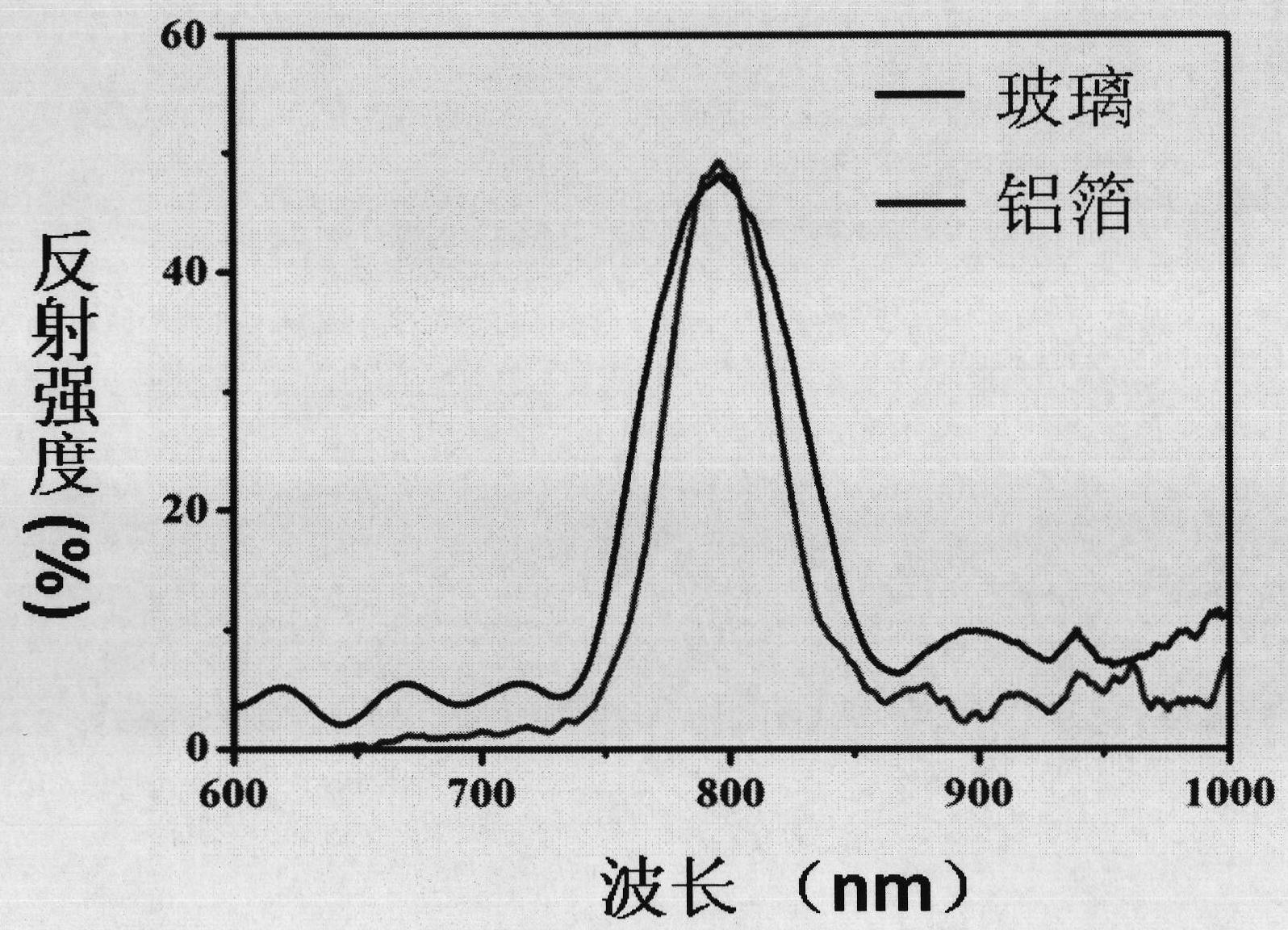

[0028] Monodisperse silica colloidal microspheres with a particle size of 300nm are ultrasonically dispersed in water to form an emulsion with a mass fraction of 0.5%, and then a polyimide film with a thickness of 0.0075cm is vertically placed in the emulsion, at temperature Under the condition of 60 ℃ and relative humidity of 60%, the above-mentioned monodisperse colloidal microspheres are assembled on the surface of the above-mentioned polyimide film by utilizing the capillary pressure of the meniscus of water formed on the surface of the polyimide film, self-assembly A large-area opal structure photonic crystal without cracks is formed, and its photonic band gap is located at 800nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com