Automatic three-spot calibration and temperature compensation method for pH measurer

A technology of temperature compensation and measuring instrument, applied in the direction of electrochemical variables of materials, etc., can solve the problems that the error of the measurement value cannot be fully compensated and the accuracy of the measuring instrument is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

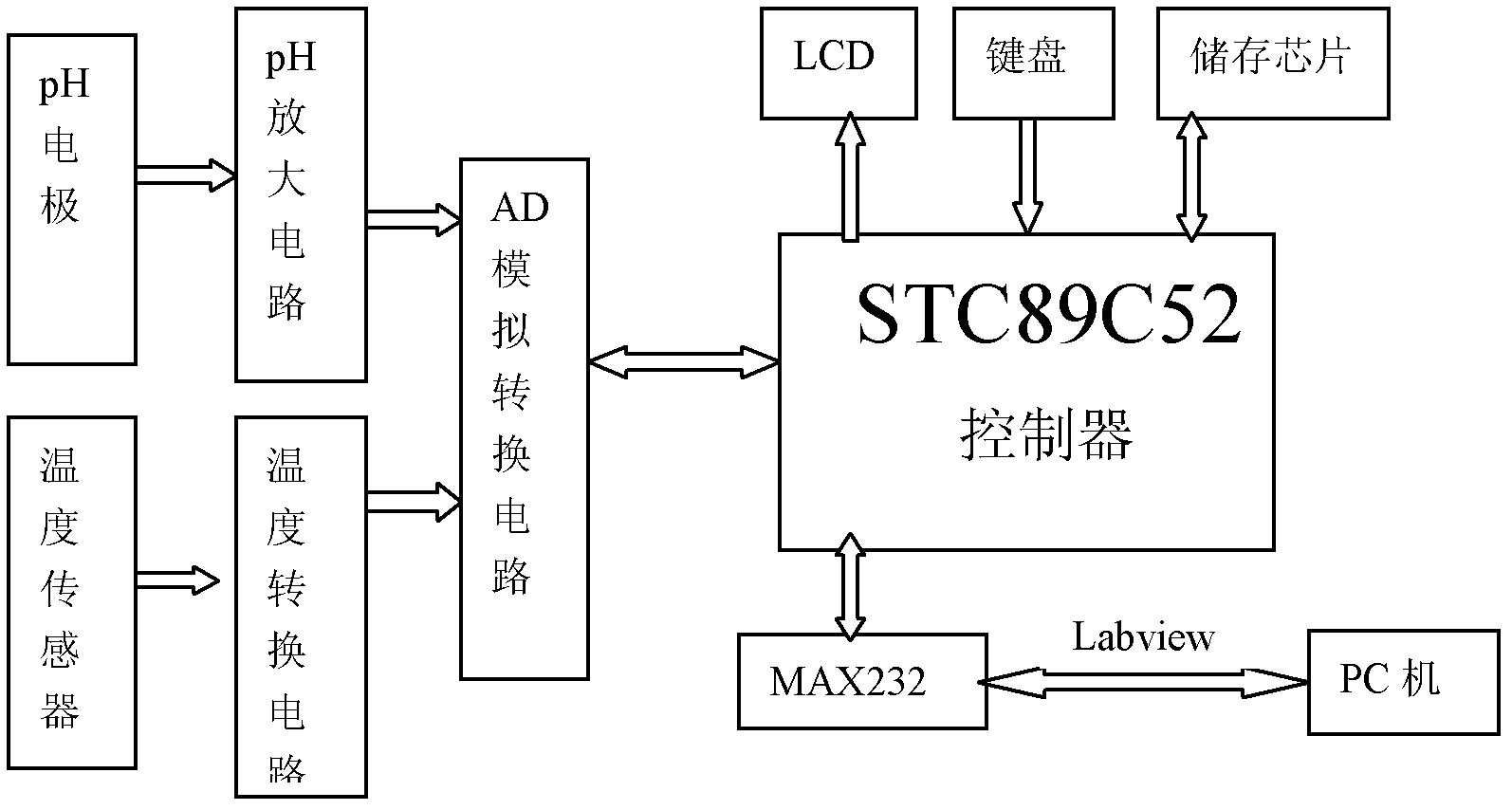

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

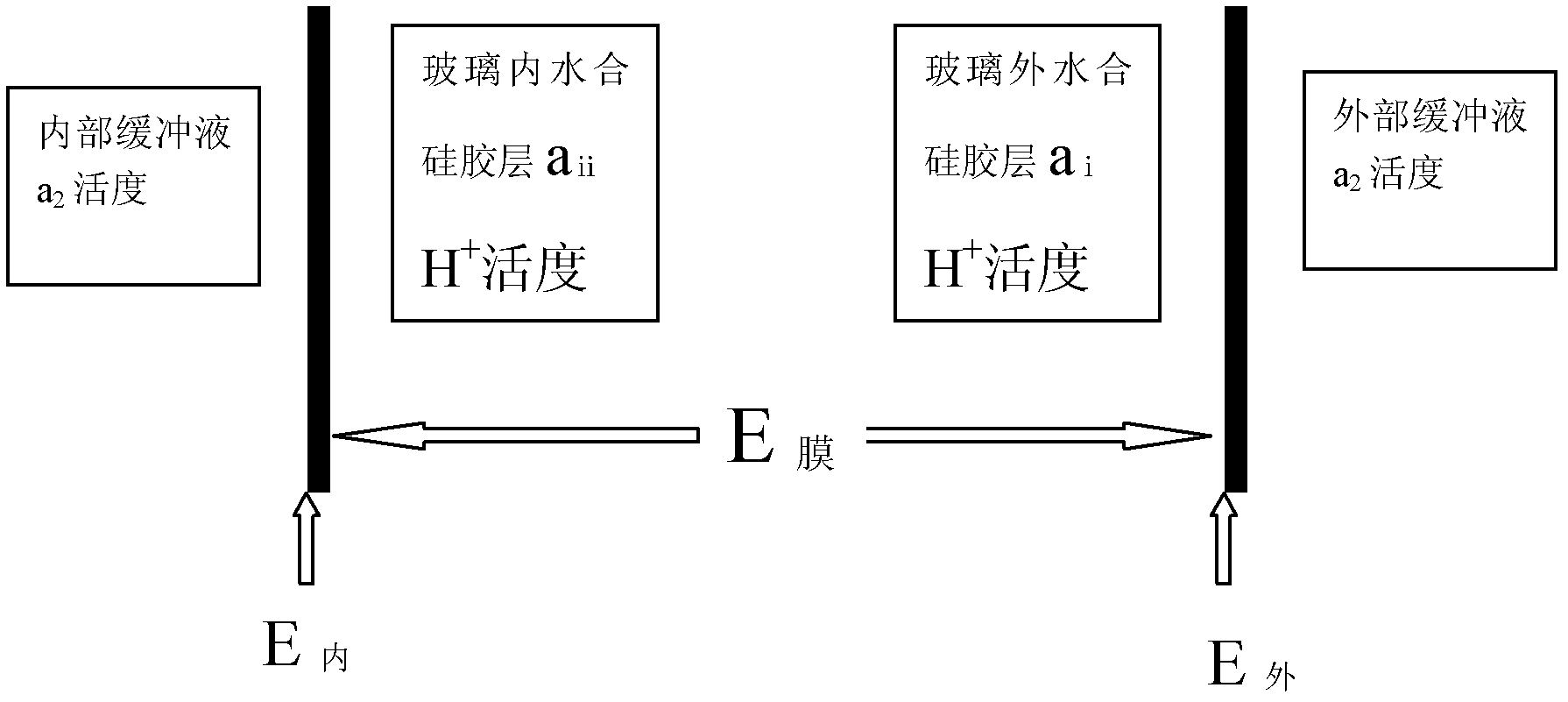

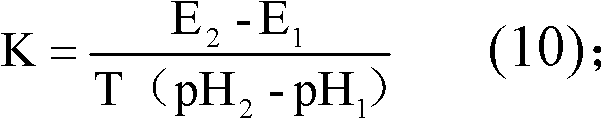

[0024] The invention adopts the composite glass electrode as the measuring electrode, and the principle of the composite glass electrode conforms to the nernst formula. According to the Nernst equation, the electrode potential is:

[0025]

[0026] E- balance electrode potential (V);

[0027] E. 标 - standard electrode potential (V);

[0028] F-Faraday's constant;

[0029] T is the absolute temperature (K) of the measured solution;

[0030] n - the number of electrons gained or lost;

[0031] R——gas constant, 8.314J / (mol K);

[0032] aOxidation state—the activity of the substance in the oxidation state, mol / L;

[0033] aReduced state—the activity of the reduced state substance, mol / L;

[0034] When the activity a oxidation state and a reduction state of the substance in the electrode reaction in formula (1) are both 1, So E=E at this time 标 .

[0035] E. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com