Optically Adhesive Polyester Film

A polyester film, adhesive technology, applied in the direction of optics, adhesives, adhesive products, etc., to achieve the effects of inhibiting machinability, excellent moisture and heat resistance, and excellent interference spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

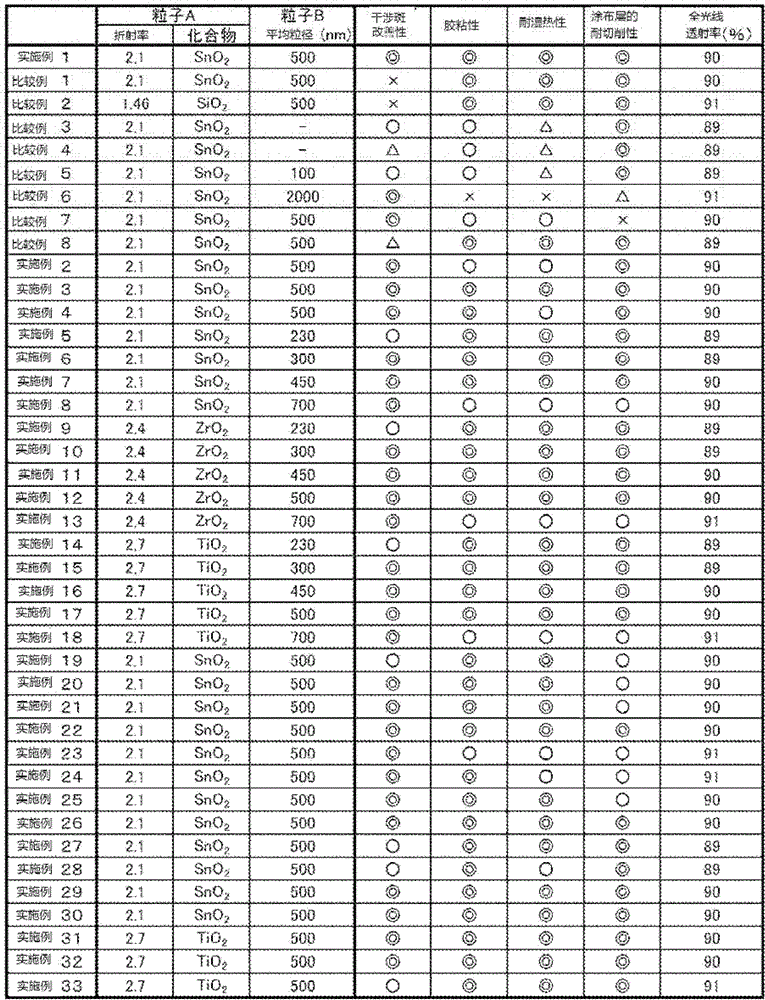

Embodiment 1

[0150] (1) Adjustment of coating liquid

[0151] The following paints were mixed to prepare a coating liquid. Particle A is SnO with a refractive index of 2.1 2 , Particle B is a silica particle with an average primary particle diameter of about 500 nm.

[0152] Water 40.16% by mass

[0153] Isopropanol 30.00% by mass

[0154] Aqueous polyester dispersion (B-1) 18.19% by mass

[0155] Block polyisocyanate aqueous dispersion (C)

[0156] 2.08% by mass

[0157] Particle A

[0158] 9.37% by mass

[0159] (Serame-su S-8 manufactured by Taki Chemical Co., Ltd., solid content concentration 8% by mass)

[0160] Particle B 0.17% by mass

[0161] (シ-hosta-KEW50 manufactured by Nippon Catalyst Co., Ltd., solid content concentration 15% by mass)

[0162] Silicone surfactant 0.03% by mass

[0163] (solid content concentration 100%)

[0164] (2) Manufacture of optically adhesive polyester film

[0165] As a film raw material ...

Embodiment 2

[0208] Except having changed the coating liquid to the following, it carried out similarly to Example 1, and obtained the laminated polyester film for optics.

[0209] Water 44.54% by mass

[0210] Isopropanol 30.00% by mass

[0211] Aqueous polyester dispersion (B-1) 12.21% by mass

[0212] Block polyisocyanate aqueous dispersion (C)

[0213] 3.67% by mass

[0214] Particle A 9.38% by mass

[0215] (Serame-su S-8 manufactured by Taki Chemical Co., Ltd., solid content concentration 8% by mass)

[0216] Particle B 0.17% by mass

[0217] (シ-hosta-KEW50 manufactured by Nippon Catalyst Co., Ltd., solid content concentration 15% by mass)

[0218] Silicone surfactant 0.03% by mass

[0219] (solid content concentration 100% by mass)

Embodiment 3

[0221] Except having changed the coating liquid to the following, it carried out similarly to Example 1, and obtained the laminated polyester film for optics.

[0222] Water 37.29% by mass

[0223] Isopropanol 30.00% by mass

[0224] Aqueous polyester dispersion (B-1) 22.09% by mass

[0225] Block polyisocyanate aqueous dispersion (C)

[0226] 1.04% by mass

[0227] Particle A

[0228] 9.38% by mass

[0229] (Serame-su S-8 manufactured by Taki Chemical Co., Ltd., solid content concentration 8% by mass)

[0230] Particle B

[0231] 0.17% by mass

[0232] (Nippon Catalyst Co., Ltd. シ-hosta-KEW50, solid content concentration 15% by mass)

[0233] Silicone surfactant 0.03% by mass

[0234] (solid content concentration 100% by mass)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com