Method for selecting potassium feldspars in potassium-bearing tailings

A technology of tailings and tailings sand, which is applied in the concentration and recovery of potassium-containing tailings in potassium feldspar, and in the field of tailings beneficiation, so as to reduce the cost of beneficiation, improve the grade of concentrate, and optimize the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

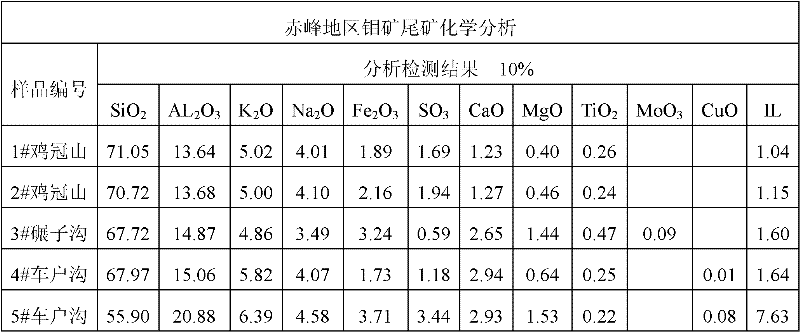

[0039] In 2010, comprehensive mineral processing was carried out for the tailings of the Chehugou copper-molybdenum mine in the Chifeng area of Inner Mongolia.

[0040] After testing the tailings sample K 2 O grade is 5.10%, Na 2 O grade is 2.79%.

[0041] Technological mineralogy has found that in addition to feldspar and quartzite, there are a small amount of sericite, chlorite and carbonate in the tailings sample, as well as trace amounts of chalcopyrite, pyrite, rutile and magnetite, Hematite, molybdenite and other metal minerals.

[0042] The sieve analysis results of the tailings sand showed that the particle size of the tailings sand was relatively coarse, and the content of +0.1mm was 86.9%; the content of -0.074mm was 9.0%.

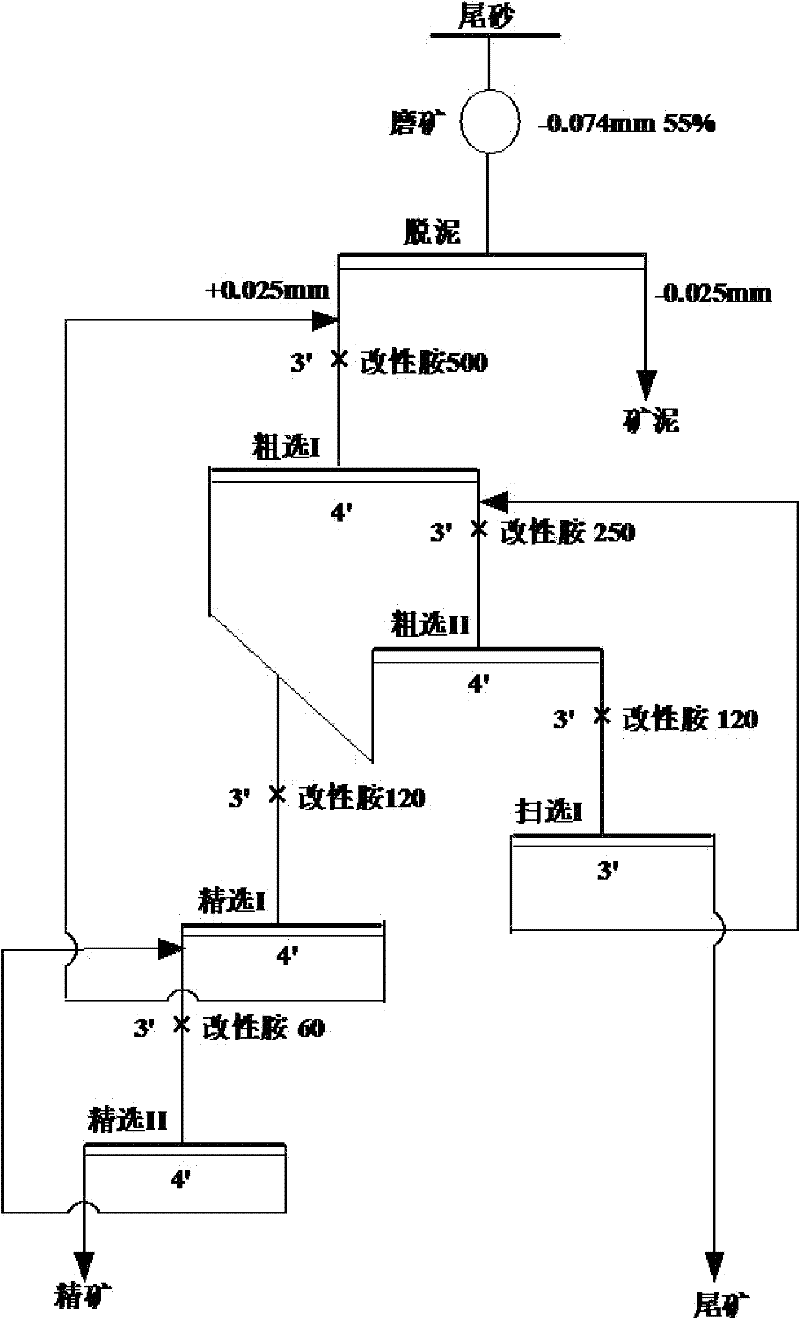

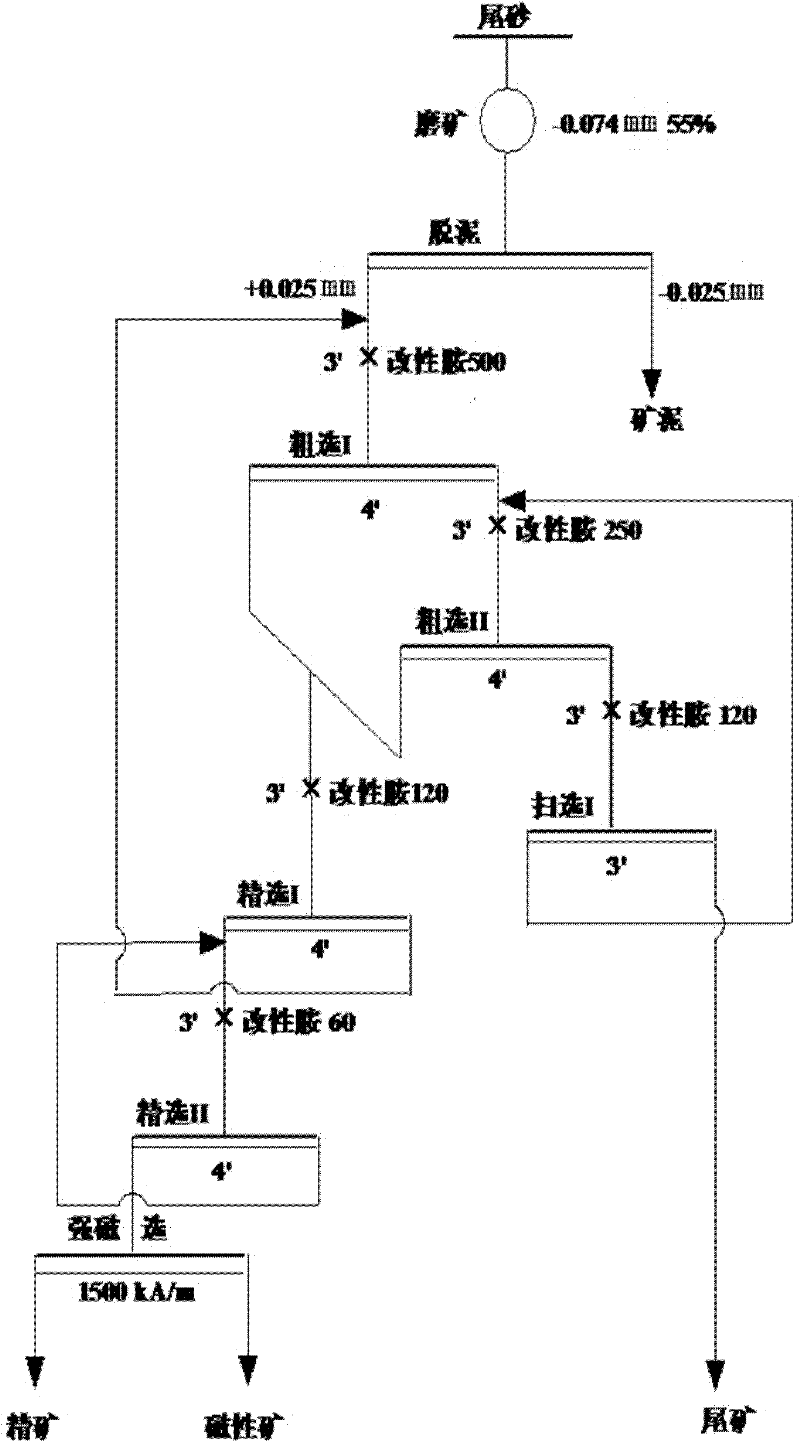

[0043] Specific beneficiation methods, such as figure 1 shown, including the following steps:

[0044] 1) Finely grind the tailings sand of the Chehugou Copper-Molybdenum Mine to a fineness of -0.074mm and a content of 55w / w%;

[0045] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com